Safe and green production method of high-quality 2, 6-difluoroaniline

A green production technology for difluoroaniline, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino compounds, etc., can solve the problems of reducing the purity of raw materials and products, and achieve the effect of reducing the amount of waste water produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

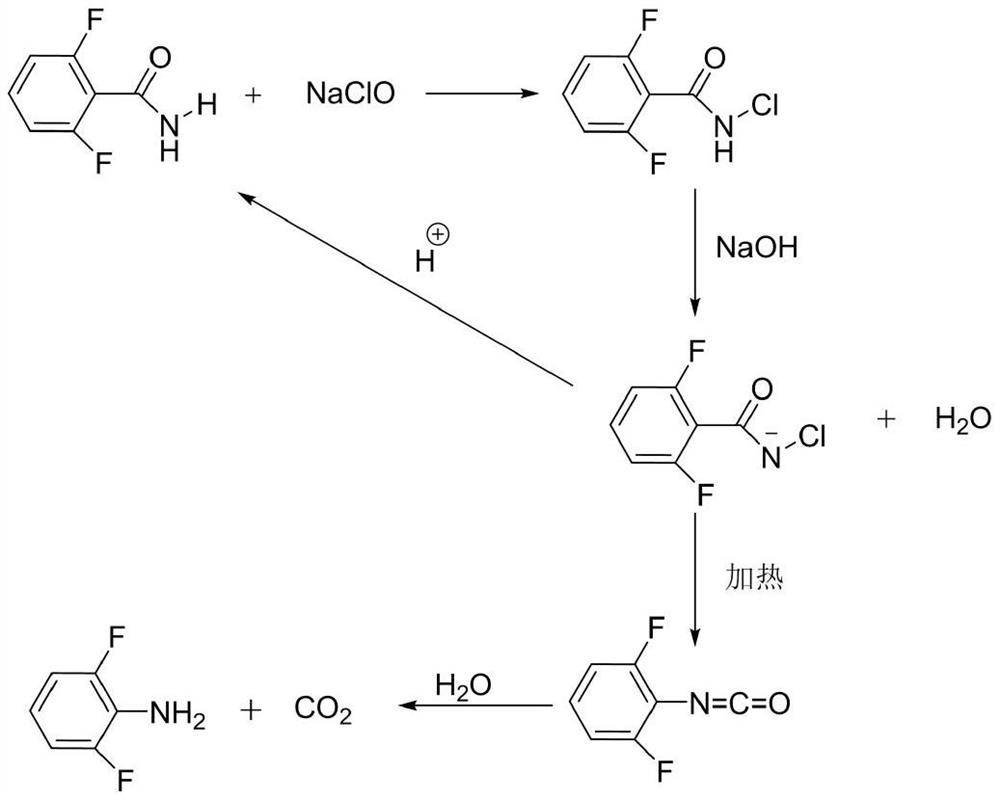

Image

Examples

Embodiment 1

[0026] Hofmann degradation reaction stages:

[0027] 2050 kilograms of water and 407 kilograms of sodium hydroxide are dropped into the reactor. Cool down to 25-35°C, and add 800 kg of 2,6-difluorobenzamide. Control the temperature at 25-35°C and add 4360 kg of sodium hypochlorite from the elevated tank. After sodium hypochlorite was added, the reaction was continued for 1.5 hours. At this point the system clarifies.

[0028] Steam distillation stage:

[0029] Put 2050 kilograms of water into another reactor, heat up to reflux with steam. Pump the above-mentioned reaction solution after the reaction to the high-level tank, and add the above-mentioned boiling water at 25-35°C while keeping it warm. At this time, a product will be formed and evaporated with water vapor. When the reaction solution was added, continue to distill until the distillate was clear and free of oil. Distillation continues until 4500 kg of recovered water is collected. The residual waste water wei...

Embodiment 2

[0033] Hofmann degradation reaction stages:

[0034] 2050 kilograms of water and 567 kilograms of potassium hydroxide are dropped into the reactor. Cool down to 25-35°C, and add 800 kg of 2,6-difluorobenzamide. Control the temperature at 25-35°C and add 4360 kg of sodium hypochlorite from the elevated tank. After sodium hypochlorite was added, the reaction was continued for 1.5 hours. At this point the system clarifies.

[0035] Steam distillation stage:

[0036] Put 2050 kilograms of water into another reactor, heat up to reflux with steam. Pump the above-mentioned reaction solution after the reaction to the high-level tank, and add the above-mentioned boiling water at 25-35°C while keeping it warm. At this time, a product will be formed and evaporated with water vapor. When the reaction solution was added, continue to distill until the distillate was clear and free of oil. Distillation continues until 4500 kg of recovered water is collected. The residual waste water ...

Embodiment 3

[0038] 2050 kilograms of embodiment one reclaimed water and 407 kilograms of sodium hydroxide are dropped in the reactor. Cool down to 25-35°C, and add 800 kg of 2,6-difluorobenzamide. Control the temperature at 25-35°C and add 4360 kg of sodium hypochlorite from the elevated tank. After sodium hypochlorite was added, the reaction was continued for 1.5 hours. At this point the system clarifies.

[0039] Steam distillation stage:

[0040] In another reactor, drop into 2050 kilograms of the reclaimed water in embodiment one, heat up to reflux with steam. Pump the above-mentioned reaction solution after the reaction to the high-level tank, and add the above-mentioned boiling water at 25-35°C while keeping it warm. At this time, a product will be formed and evaporated with water vapor. When the reaction solution was added, continue to distill until the distillate was clear and free of oil. Distillation continues until 4500 kg of recovered water is collected. The residual wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com