A kind of vegetable oil derivative modified amphoteric polyurethane retanning agent and preparation method thereof

A technology of vegetable oil derivatives and polyurethane, which is applied in the field of leather retanning agents, can solve the problems of no related research on retanning agents, and achieve good biodegradability, low reaction temperature, and simple synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

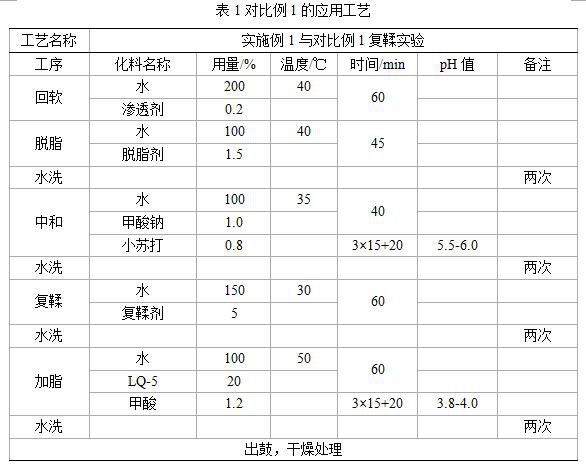

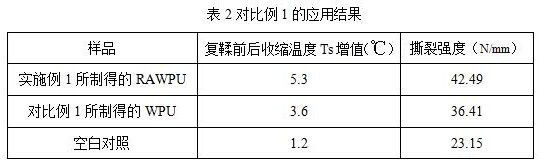

Examples

Embodiment 1

[0018] Embodiment 1: be the amphoteric polyurethane of isocyanate synthetic ricinoleic acid modification by IPDI

[0019] Polyurethane prepolymer was obtained by reacting isophorone diisocyanate (IPDI), polytetrahydrofuran diether alcohol (PTMG-1000) and dibutyltin dilaurate (DBTDL) at 60°C for 3 h; Methylolpropionic acid (DMPA) and N ~Methyldiethanolamine (MDEA) was reacted for 3 hours; then ricinoleic acid (RA) was added to react for 3 hours; then the temperature was lowered to 40°C, neutralized by adding triethylamine, and emulsified with distilled water to obtain translucent blue light Amphoteric polyurethane emulsion.

[0020] IPDI:PTMG-1000:DMPA:MEDA:Molar ratio=16:5:3:3:3 of RA.

Embodiment 2

[0021] Embodiment 2: Change isocyanate from IPDI to diphenylmethane diisocyanate (MDI)

[0022] The polyurethane prepolymer was obtained by reacting diphenylmethane diisocyanate (MDI), PTMG-1000, and DBTDL at 65°C for 2 h; the temperature was raised to 85°C, and DMPA and MDEA were added to react for 2 h; then RA was added to react for 2 h; Lower the temperature to 45°C, add triethylamine for neutralization, and emulsify with distilled water to obtain a translucent blue-light amphoteric polyurethane emulsion.

[0023] The molar ratio of MDI:PTMG-1000:DMPA:MEDA:RA=16: 5: 3: 4: 2

Embodiment 3

[0024] Embodiment 3: Change isocyanate from IPDI to toluene diisocyanate (TDI)

[0025] React toluene diisocyanate (TDI) and PTMG-1000DBTDL at 75°C for 3 h to obtain a polyurethane prepolymer; raise the temperature to 90°C, add DMPA and MDEA to react for 3 h; then add RA for 2 h; then lower the temperature to Add triethylamine to neutralize at 50°C, and emulsify with distilled water to obtain translucent blue-light amphoteric polyurethane emulsion.

[0026] The molar ratio of TDI:PTMG-1000:DMPA:MEDA:RA=16:5:3:3.5:3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com