Epoxy resin micro-nano blended composite material for packaging power electronic high-power device and preparation method thereof

A high-power device, epoxy resin technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of increasing the interface and limiting the conductivity of composite materials, so as to achieve thermal conductivity, promote heat conduction network, and promote Dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

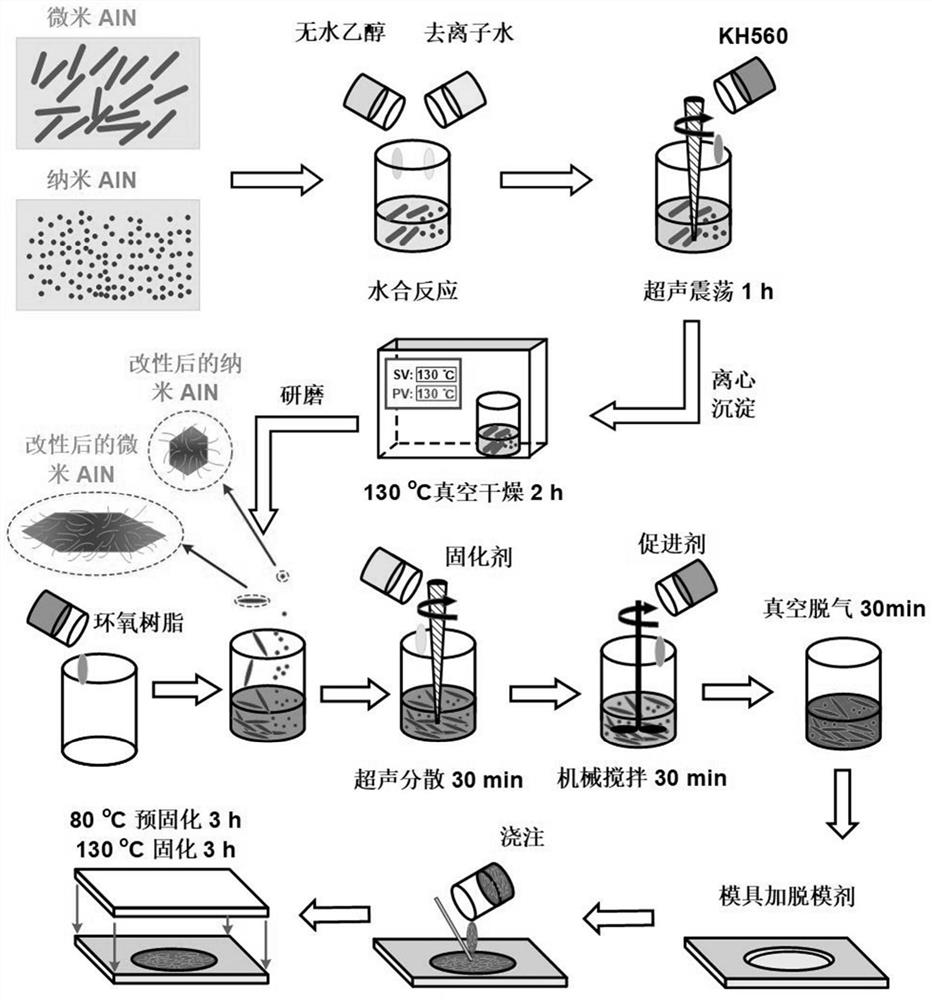

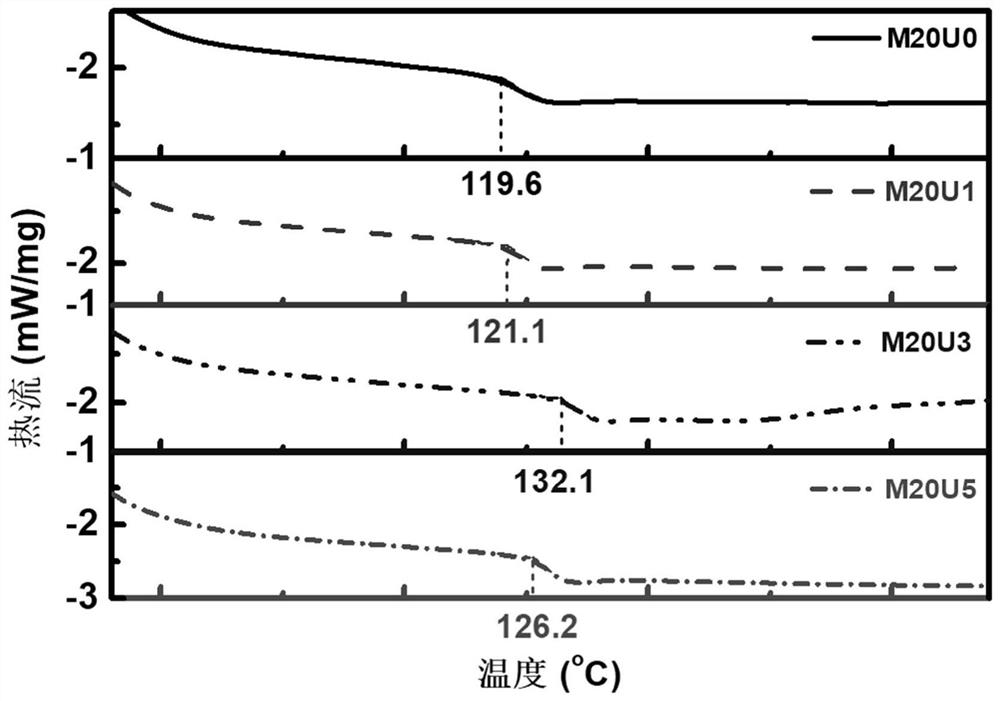

[0036] An epoxy resin micro-nano blend composite material for encapsulation of power electronic high-power devices, according to the parts by mass, the preparation method is as follows:

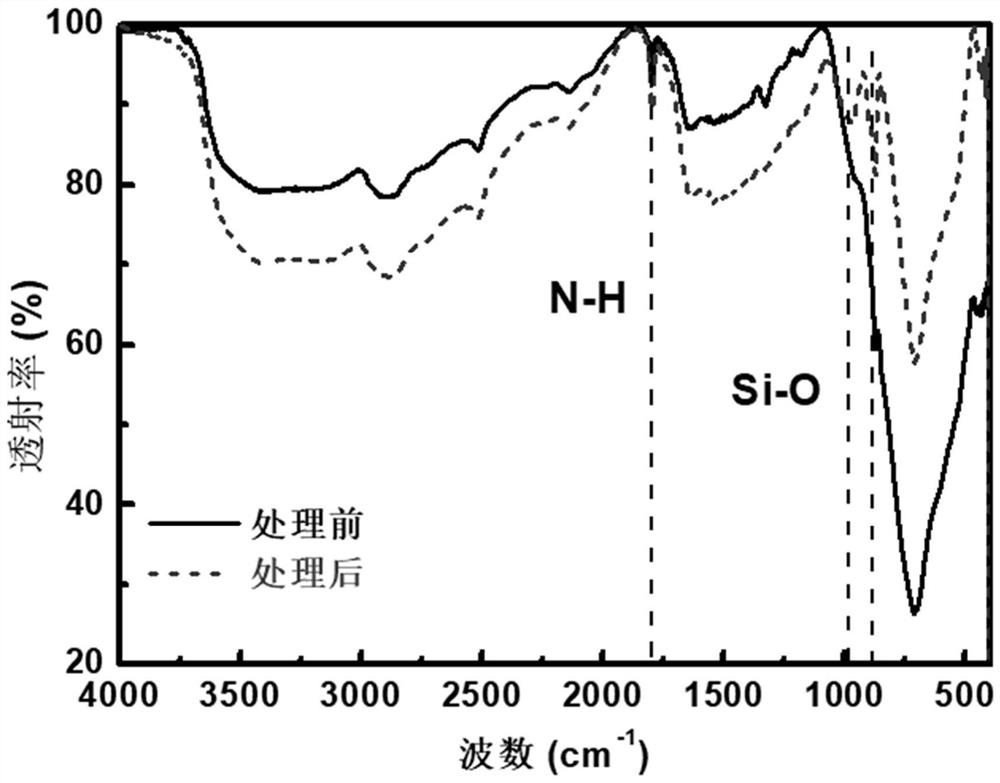

[0037] 1 Put 45.5 parts of micron aluminum nitride in a vacuum oven at 130°C for drying, put absolute ethanol and distilled water in 34.2 parts: 11.4 parts into a beaker and mechanically stir for 1 minute, then dry the dried micronano aluminum nitride Hydration reaction occurs at 40°C in the ethanol aqueous solution of Granule Road;

[0038] 2 Add 3 parts of silane coupling agent KH560 to the solution, oscillate ultrasonically for 30 minutes, then use a centrifuge to separate the micro-nano aluminum nitride from the solution, put it in a vacuum oven at 130°C for 2 hours, grind and dry to obtain the modified Micronano aluminum nitride particles;

[0039] 3 Put the micro-nano aluminum nitride into 100 parts of epoxy resin, ultrasonically disperse the mixed solution at 40°C for 1 hour, and let ...

Embodiment 2

[0043] An epoxy resin micro-nano blend composite material for encapsulation of power electronic high-power devices, according to the parts by mass, the preparation method is as follows:

[0044] 1 Put micron aluminum nitride and nano aluminum nitride particles in 46 parts: 2.3 parts into a vacuum drying oven at 130°C for drying, and put anhydrous ethanol and distilled water in a beaker according to 36.3 parts: 12.1 parts and mechanically stir for 1 minute, Then, the dried micronano-aluminum nitride particles are hydrated at 40°C in an aqueous ethanol solution;

[0045] 2 Add 3.1 parts of silane coupling agent KH560 to the solution, oscillate ultrasonically for 30 minutes, then use a centrifuge to separate the micro-nano aluminum nitride from the solution, put it in a vacuum oven at 130°C for 2 hours, grind and dry to obtain the modified Micronano aluminum nitride particles;

[0046] 3 Put the micro-nano aluminum nitride into 100 parts of epoxy resin, ultrasonically disperse t...

Embodiment 3

[0050] An epoxy resin micro-nano blend composite material for encapsulation of power electronic high-power devices, according to the parts by mass, the preparation method is as follows:

[0051] 1 Put the micron aluminum nitride and nano aluminum nitride particles in 47.5 parts: 7.1 parts in a vacuum drying oven at 130°C for drying, and put anhydrous ethanol and distilled water in a beaker according to 42 parts: 13 parts and mechanically stir for 1 minute, Then, the dried micronano-aluminum nitride particles are hydrated at 40°C in an aqueous ethanol solution;

[0052] 2 Add 3.5 parts of silane coupling agent KH560 to the solution, oscillate ultrasonically for 30 minutes, then use a centrifuge to separate the micro-nano aluminum nitride from the solution, put it in a vacuum oven at 130°C for 2 hours, grind and dry to obtain the modified Micronano aluminum nitride particles;

[0053] 3 Put the micro-nano aluminum nitride into 100 parts of epoxy resin, ultrasonically disperse t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com