Microbial remediation agent and preparation method thereof

A technology of microbial remediation and bacterial agent, applied in the field of microbial remediation, can solve the problems of complex process and high treatment cost, and achieve the effect of simple treatment process, short cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

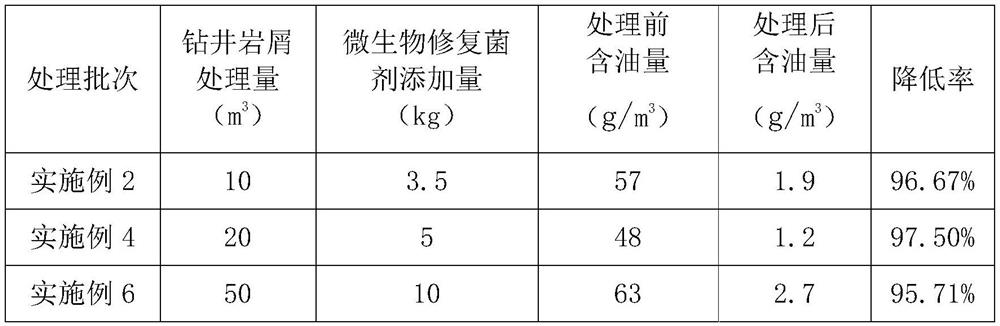

Examples

Embodiment 1

[0026] Embodiment 1: a kind of microbiological restoration bacterium agent, it comprises the raw material of following weight portion: 10 parts of Acinetobacter calcium acetate; 20 parts of Bacillus subtilis; 5 parts of Bacillus licheniformis; 15 parts of Pseudomonas aeruginosa; Dentella 25 parts; Pseudomonas saccharolyticus 15 parts; Microbacterium oxidans 5 parts; Denitrifying Achromobacter 20 parts. Among them, Acinetobacter calcium acetate has the function of degrading alkanes; Bacillus subtilis has the function of producing surfactant; Bacillus licheniformis has the function of degrading alkanes; Pseudomonas aeruginosa has the function of producing surfactant; It has the function of degrading organic oil; Pseudomonas saccharolyticum has the function of degrading organic oil; Microbacterium oxidizer has the function of degrading organic oil; Achromobacter denitrifying has the function of degrading polymer; the above bacteria can be coordinated after being combined in propor...

Embodiment 2

[0028] Embodiment 2: the preparation method of embodiment 1 microbial repair bacterial agent, it comprises the steps: (1) take bacterial classification by following weight ratio; (2) bacterial classification activation; (3) primary seed fermentation; (4) Secondary seed fermentation; (5) industrial fermentation; (6) component deployment to prepare the finished microbial restoration liquid bacterial agent; among them,

[0029] (1) Take raw materials by weight ratio as follows: 10 parts of Acinetobacter calcoacetate; 20 parts of Bacillus subtilis; 5 parts of Bacillus licheniformis; 15 parts of Pseudomonas aeruginosa; 15 parts of pseudopallidum; 5 parts of microbacterium oxidizer; 20 parts of denitrifying achromobacter;

[0030] (2) Strain activation: the bacterial strains Acinetobacter calcium acetate bacterial classification, Bacillus subtilis bacterial classification, Bacillus licheniformis bacterial classification, Pseudomonas aeruginosa bacterial classification, alkane-eating...

Embodiment 3

[0036] Embodiment 3: a kind of microbiological restoration bacterium agent, it comprises the raw material of following weight portion: 1 part of Acinetobacter calcium acetate; 10 parts of Bacillus subtilis; 1 part of Bacillus licheniformis; 5 parts of Pseudomonas aeruginosa; Dentella 1 part; Pseudomonas saccharolyticus 10 parts; Microbacterium oxidans 1 part; Denitrifying Achromobacter 1 part. Among them, Acinetobacter calcium acetate has the function of degrading alkanes; Bacillus subtilis has the function of producing surfactant; Bacillus licheniformis has the function of degrading alkanes; Pseudomonas aeruginosa has the function of producing surfactant; It has the function of degrading organic oil; Pseudomonas saccharolyticum has the function of degrading organic oil; Microbacterium oxidizer has the function of degrading organic oil; Achromobacter denitrifying has the function of degrading polymer; the above bacteria can be coordinated after being combined in proportion Coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com