High-stability all-inorganic CsPbI2Br perovskite thin film and preparation method thereof

A high-stability, perovskite technology, applied in coatings, photovoltaic power generation, electrical components, etc., can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Clean the FTO conductive glass substrate (2×2.5cm 2 ), then use N 2 Dry and treat with ultraviolet ozone for 15 minutes;

[0039] 2) TiO 2 The sol was coated on the FTO conductive glass substrate and rotated at a speed of 3000rpm for 30s, and then annealed in air at 500°C for 60min; after natural cooling to room temperature, a dense TiO 2 layer (~60nm);

[0040] 3) methylamine bromide is dissolved in organic solvent A methanol and isopropanol, and the molar concentration is made into a 0.1mol / L solution as an antisolvent;

[0041] 4) According to the molar ratio of 1:1:2 with 277mg PbI 2 , 222mg PbBr 2 and 312mg CsI were completely dissolved in DMSO, stirred at room temperature for 12h, and prepared as CsPbI with a molar concentration of 1.2mol / L 2 Br precursor solution;

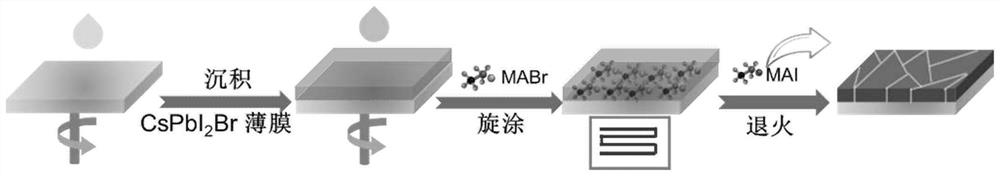

[0042] 5) Then apply the precursor solution to the FTO / TiO 2 On the substrate, the deposited CsPbI 2 Before the Br perovskite film, use ultraviolet ozone treatment for 10min; rotate at a s...

Embodiment 2

[0046] 1) Clean the FTO conductive glass substrate (2×2.5cm 2 ), then use N 2 Dry and treat with ultraviolet ozone for 15 minutes;

[0047] 2) TiO 2 The sol was coated on the FTO conductive glass substrate and rotated at a speed of 3000rpm for 30s, and then annealed in air at 500°C for 60min; after natural cooling to room temperature, a dense TiO 2 layer (~60nm);

[0048] 3) methylamine bromide is dissolved in organic solvent A toluene, and the molar concentration is made into a solution of 0.05mol / L as anti-solvent;

[0049] 4) According to the molar ratio of 1:1:2, 277mg PbI 2 , 222mg PbBr 2 and 312mg CsI were completely dissolved in DMF, stirred at room temperature for 12h, and prepared into CsPbI with a molar concentration of 1.25mol / L 2 Br precursor solution;

[0050] 5) Then apply the precursor solution to the FTO / TiO 2 On the substrate, the deposited CsPbI 2 Before the Br perovskite film, use ultraviolet ozone treatment for 15min; rotate at a speed of 1800rpm f...

Embodiment 3

[0054] 1) Clean the FTO conductive glass substrate (2×2.5cm 2 ), then use N 2 Dry and treat with UV-ozone for 15min.

[0055] 2) TiO 2 The sol was coated on the FTO conductive glass substrate and rotated at 3000rpm for 30s, and then annealed in air at 500°C for 60min. After natural cooling to room temperature, dense TiO 2 layer (~60nm);

[0056] 3) methylamine bromide is dissolved in organic solvent A chlorobenzene, is made into molar concentration and is 0.2mol / L solution as anti-solvent;

[0057] 4) According to the molar ratio of 1:1:2, 277mg PbI 2 , 222mg PbBr 2 and 312mg CsI were completely dissolved in DMSO, stirred at room temperature for 12h, and prepared as CsPbI with a molar concentration of 0.6mol / L 2 Br precursor solution;

[0058] 5) Then apply the precursor solution to the FTO / TiO 2 On the substrate, the deposited CsPbI 2 Before the Br perovskite film, use ultraviolet ozone treatment for 5min; rotate at a speed of 2000rpm for 20s, and then rotate at a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com