Preparation method of reusable solid-phase extraction material based on beta-cyclodextrin

A solid-phase extraction material, β-cyclodextrin technology, applied in the field of environmental chemistry and analysis and detection, can solve the problems of insufficient sensitivity of the instrument, low target content, inaccurate determination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

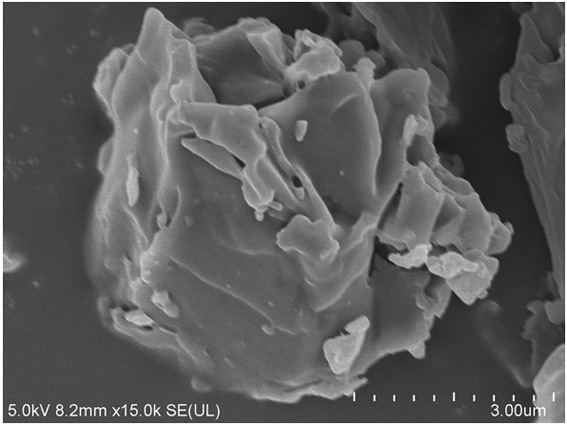

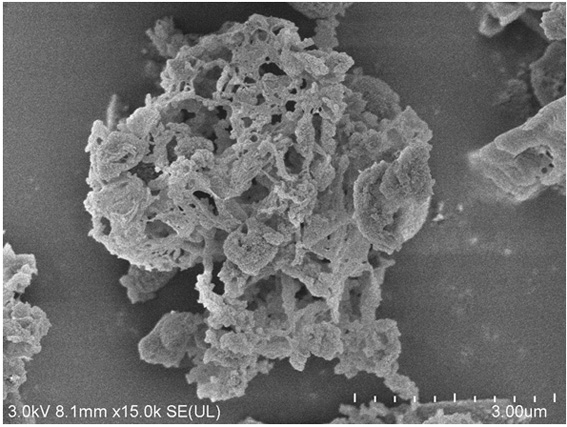

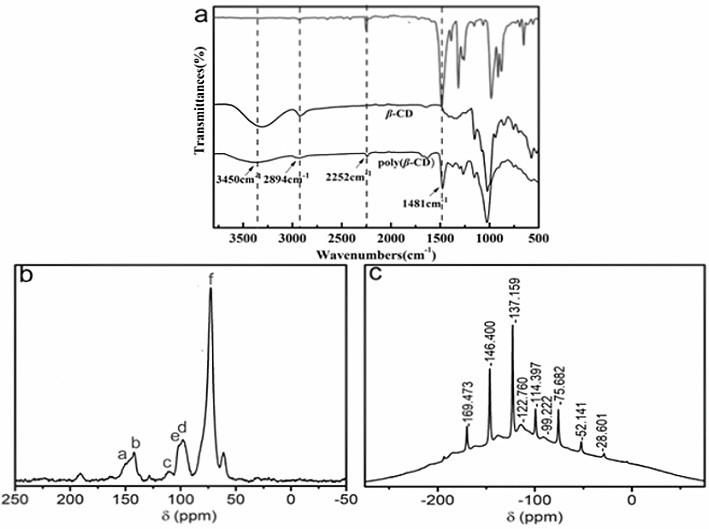

Image

Examples

preparation example Construction

[0028] A method for preparing a reusable solid phase extraction material based on β cyclodextrin, the specific steps are as follows:

[0029] (1) Add 0.10-0.50mol β-cyclodextrin, 0.10-0.50mol benzene-containing halide, 0.10-0.50mol carbonate in a flame-dried scintillation counting flask, and fill with nitrogen for 5 minutes;

[0030] (2) Add 5-10 mL of organic solvent A, 0.1-0.3 mol of initiator, and fill with nitrogen for 5 minutes;

[0031] (3) Turn off the nitrogen and react for 36-72h under the conditions of 70-90℃ and stirring speed of 300-500 r / min;

[0032] (4) Wash the polymer synthesized by the reaction with 1M acid until there is no bubbling, then wash with deionized water several times, then wash with organic solvent A twice, and organic solvent B twice;

[0033] (5) The polymer after washing is vacuum dried at 40°C for 24h, or liquid nitrogen at -196°C for 10min to prepare β-cyclodextrin polymer which can be used as solid phase extraction material.

[0034] Wherein, the benze...

Embodiment 1

[0042] (1) Add 0.10mol β-cyclodextrin, 0.10mol tetrachloroterephthalonitrile, and 0.10mol calcium carbonate to a flame-dried scintillation counting flask, and fill with nitrogen for 5 min;

[0043] (2) Add 5 mL of butyl acetate, 0.1 mol of benzophenone, and fill with nitrogen for 5 minutes;

[0044] (3) Turn off the nitrogen, and react for 36 hours at 70°C and a stirring speed of 400 r / min;

[0045] (4) Wash the polymer synthesized by the reaction with 1M acid until no bubbling, then wash it with deionized water several times, then wash it with butyl acetate twice, and wash it twice with diethyl ether;

[0046] (5) The polymer after washing is vacuum dried at 40°C for 24 hours to prepare β-cyclodextrin polymer which can be used as solid phase extraction material.

Embodiment 2

[0048] (1) Add 0.20mol β-cyclodextrin, 0.30mol decafluorobiphenyl, 0.15mol sodium carbonate to a flame-dried scintillation counting flask, and fill it with nitrogen for 5 minutes;

[0049] (2) Add 6 mL of propanol, 0.2 mol of azobisisobutyronitrile, and fill with nitrogen for 5 minutes;

[0050] (3) Turn off the nitrogen, and react for 72 hours at 80°C and a stirring speed of 300 r / min;

[0051] (4) Wash the polymer synthesized by the reaction with 1M acid until there is no bubbling, then wash it with deionized water several times, then wash it twice with propanol and twice with isobutanol;

[0052] (5) Dry the polymer after washing with liquid nitrogen at -196°C for 10 minutes to prepare β-cyclodextrin polymer that can be used as a solid phase extraction material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com