Homogeneous catalyst and heterogeneous catalyst based on ionic liquid, and preparation methods and application thereof

A heterogeneous catalyst, homogeneous catalyst technology, applied in the synthesis of new strong basic ionic liquid, new ionic liquid riveting field, can solve the problem of weak alkalinity, poor nucleophilicity, poor stability of strong basic ionic liquid, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

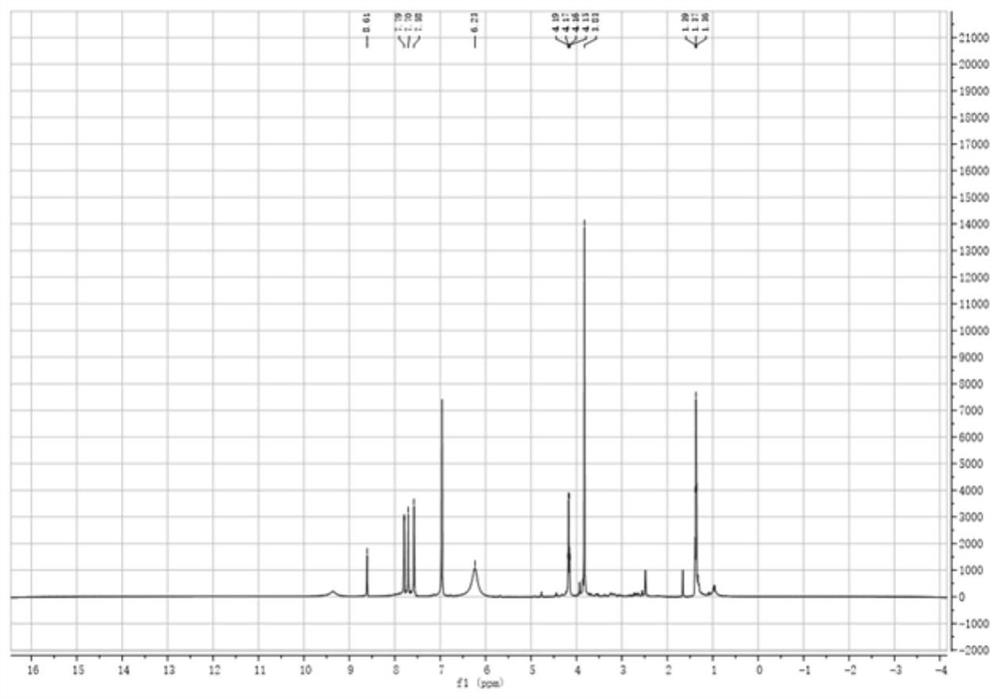

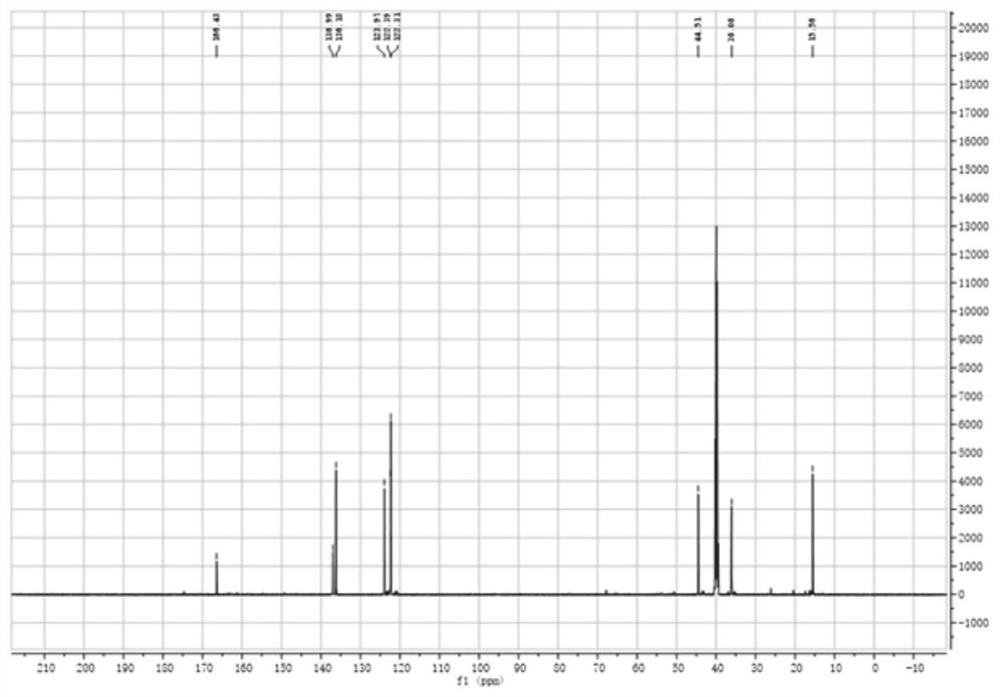

[0127] The specific preparation method of 1-ethyl-3-methylimidazolium imidazolium salt: dissolve 0.5mol imidazole in 60mL ethanol solvent, add equimolar potassium ethoxide to a three-necked flask, stir vigorously at 60°C for 6h, and the reaction is over Finally, under the condition of 65°C in an oil bath, the solvent ethanol and the product ethanol were removed by rotary evaporation under reduced pressure for 2 hours, and dried in a vacuum drying oven for 12 hours to constant weight to prepare imidazole potassium salt. 0.5 mol of commercially purchased [EmIm]Br was added into a three-necked flask, and potassium imidazole was added in an equimolar ratio under the condition of ethanol with water as a solvent, and the reaction was stirred at room temperature for 24 hours. After the reaction was completed, the resulting white solid KBr was removed by filtration, and the solvent was removed by rotary evaporation under reduced pressure for 2 hours in an oil bath at 65°C, and dried in...

Embodiment 2

[0130] Table 1 is a comparison of the activities of commercially purchased ionic liquids and ionic liquids synthesized in the laboratory for the transesterification of dimethyl carbonate and ethanol. Catalyst evaluation conditions are as follows: 46g ethanol and 90g dimethyl carbonate reaction raw materials (molar ratio: 1:1) are uniformly mixed in a 250mL flask, magnetically stirred, the reaction system is heated to 76-78°C, and about 2.72g of ion is added after the reflux is stable. The mass of the liquid and the ionic liquid accounts for 2% of the mass of the reaction raw materials, and the reaction time is 30-240min. The commercially purchased ionic liquids are: 1-ethyl-3-methylimidazolium acetate, 1-ethyl-3-methylimidazolium chloride, 1-ethyl-3-methylimidazolium bromide, 1- Ethyl-3-methylimidazolium iodide, 1-butyl-3-methylimidazolium fluoroborate, 1-butyl-3-methylimidazolium chloride, 1-butyl-3-methylimidazolium bromide salt, 1-butyl-3-methylimidazolium iodide salt, 1,3...

Embodiment 3

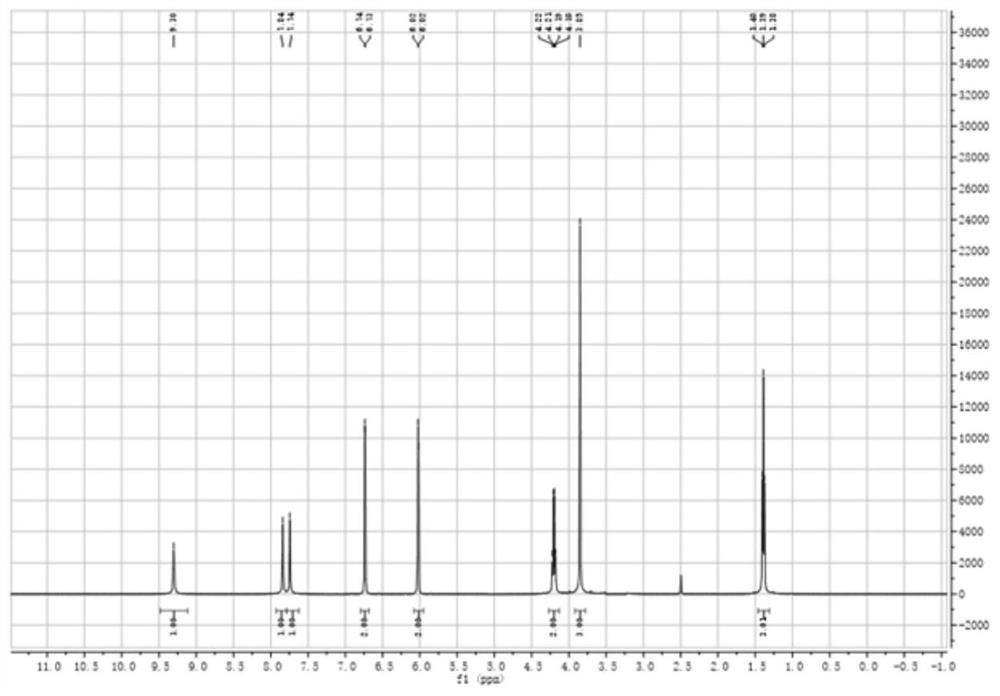

[0137] With 1-butyl-3-methylimidazolium pyrrole salt as catalyst, the initial state of the catalyst is as follows Figure 5 As shown, the color of the prepared ionic liquid is transparent light yellow.

[0138] 1-butyl-3-methylimidazolium pyrrole salt catalyst reuse evaluation conditions are, 46g ethanol and 90g dimethyl carbonate reaction raw materials (molar ratio is 1:1) are uniformly mixed in a 250mL flask, magnetically stirred, and the temperature of the reaction system is raised to 76-78°C, after the reflux is stable, add about 2.72g of 1-butyl-3-methylimidazolium pyrrole salt ionic liquid, the mass of the ionic liquid accounts for 2% of the mass of the reaction raw materials, and the reaction time is 30min. After the reaction, the reaction raw materials, products and ionic liquid were rotary evaporated at 110° C. for 30 minutes under reduced pressure. The remaining liquid in the rotary evaporator is the 1-butyl-3-methylimidazole pyrrole salt catalyst, which is directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com