Preparation method and application of porphyrin-metal organic framework material

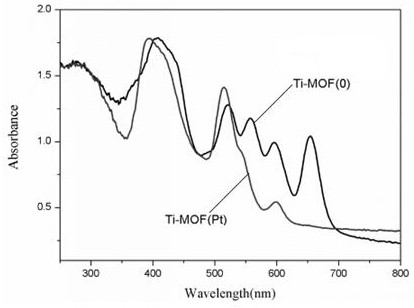

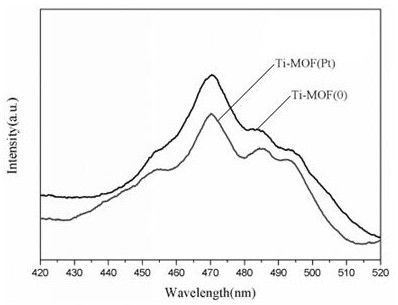

A technology of metal-organic framework and porphyrin, which is applied in the field of preparation of porphyrin-metal-organic framework materials, can solve the problems of low transfer rate and separation efficiency of photogenerated carriers, and low photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of Pt-TCPP

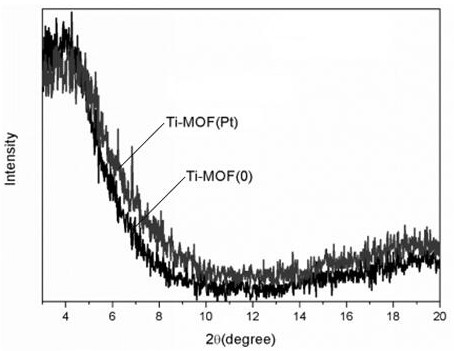

[0032] 1) see figure 1 , 6.9 g of methyl 4-formylbenzoate was completely dissolved in 100 mL of propionic acid, 3 mL of pyrrole was added dropwise, and the mixture was refluxed for 12 h. After the reaction, the mixture was cooled to room temperature, and the precipitate was obtained by suction filtration. , the collected precipitate was washed with ethyl acetate and THF and dried at 70°C for 12 h to obtain a purple powder, which was TMCPP;

[0033] 2) Add 452mg of PtCl 2 and 724mg TMCPP were added to 100mL benzonitrile, and at 190°C and N 2 Reflux overnight under air. After cooling, the solvent was spin-dried, and the resulting residue was purified by column chromatography to obtain PtTMCPP. The obtained solid was added to 20 mL, 2 mol / L KOH aqueous solution and THF / MeOH 1:1 mixed solution and refluxed for 12 h. After cooling to room temperature, part of the solvent was removed, and the solution was acidified with 1M HCl until no more p...

Embodiment 2-5

[0040] In Example 2-5, the same method as in Example 1 was used to prepare the porphyrin-metal organic framework material, wherein the ingredients and ratios in Example 2-5 are shown in Table 1.

[0041] Ingredient list in table 1 embodiment 2-6

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com