Preparation method of artificial graphite material special for lithium ion battery negative electrode

A lithium-ion battery, artificial graphite technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as high price, inability to achieve high capacity and high rate performance, and complex negative electrode production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

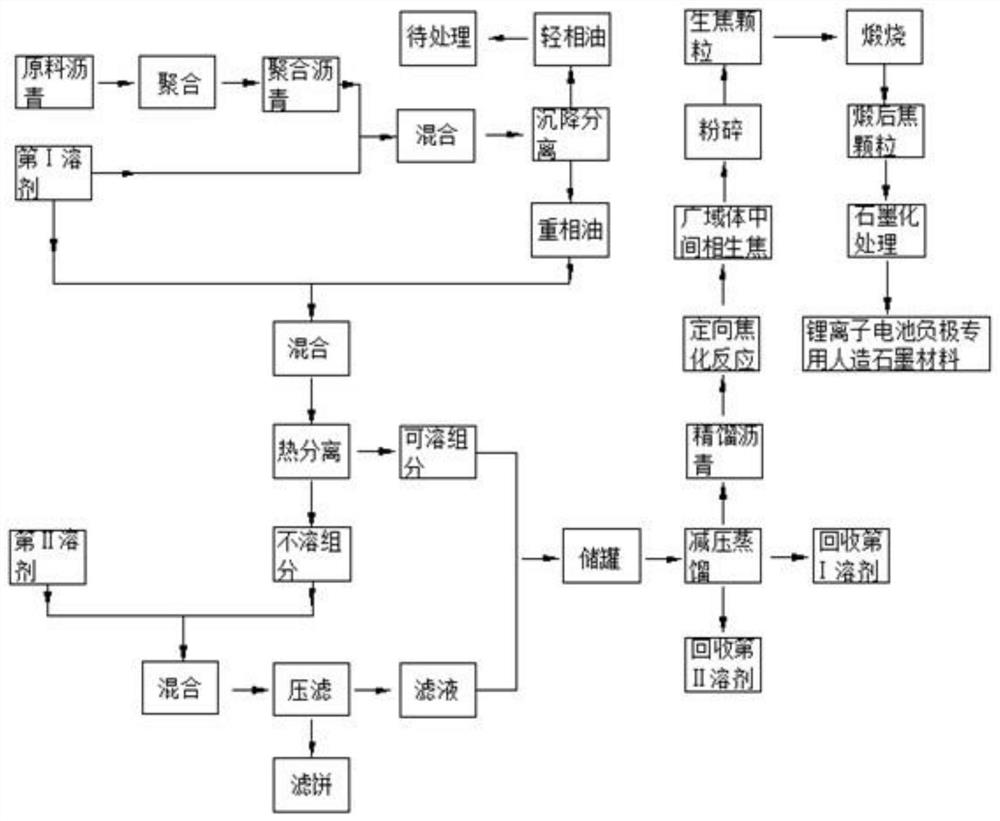

[0050] Such as figure 1 Shown, the preparation method of a kind of lithium-ion battery negative electrode special-purpose artificial graphite material of the present invention, comprises the steps:

[0051] Step 1, according to the reactivity of the high-reactivity components contained in the raw pitch, by controlling the thermal reaction conditions, the raw pitch undergoes a thermal polymerization reaction in an inert atmosphere to form microcrystalline units to obtain polymerized pitch; the thermal polymerization The reaction temperature is 350-400°C, the constant temperature time is 0.5-8h, and the heating rate is 0.5-5°C / min;

[0052] Step 2: Mix the polymerized asphalt obtained in Step 1 with the first solvent according to the set solvent-oil ratio, and then carry out static sedimentation separation after full stirring, and separate according to the set ratio to obtain light phase oil and heavy phase oil, and light phase oil As a by-product asphalt oil to be treated; the...

Embodiment 1

[0077] In this embodiment, the raw pitch is coal-based soft pitch with a softening point of 30°C, and its quinoline insoluble matter content is 1.83%. The heating rate was raised from room temperature to 400°C at a rate of min, and the temperature was kept at a constant temperature for 4 hours to form microcrystalline units and obtain polymerized pitch.

[0078]Mix the polymerized asphalt and wash oil at a mass ratio of 3:1, stir well at a temperature of 120°C, and then pour it into a static settling device with a length-to-diameter ratio of 8:1 for settling and separation. The settling temperature is 130°C, and the settling time is 3h, then separate the light phase oil and heavy phase oil according to the mass ratio of 8:2, and measure the density of the light phase oil to be 1.0g / cm 3 , the heavy phase oil density is 1.3g / cm 3 . Mix according to heavy phase oil:washing oil mass ratio of 1:3, heat to 70°C, fully stir for 2h, centrifugal speed 800rad / min, separation solid ph...

Embodiment 2

[0083] In this embodiment, the raw pitch is coal-based soft pitch with a softening point of 70°C, and its quinoline insoluble matter content is 3.85%. Raise the temperature from room temperature to 390°C at a rate of min, and stay at constant temperature for 5 hours to form microcrystalline units and obtain polymerized pitch.

[0084] Mix the polymerized asphalt and dianthracene oil at a mass ratio of 2:1, stir well at 150°C, and then pour it into a static settling device with a length-to-diameter ratio of 9:1 for settling and separation. The settling temperature is 140°C and the settling time is for 3 hours, then separate the light phase oil and heavy phase oil according to the mass ratio of 7:3, and measure the density of the light phase oil to be 0.9g / cm 3 , the heavy phase oil density is 1.2g / cm 3 . Mix heavy phase oil: dianthracene oil at a mass ratio of 1:4, heat to 80°C, stir thoroughly for 2 hours, centrifuge at 1000rad / min, and separate solid phase density at 1.1g / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com