Acetic acid-magnesium acetate liquid carbon source as well as production process and application thereof

A liquid carbon source and production process technology, applied in chemical instruments and methods, biological water/sewage treatment, special compound water treatment, etc., can solve the problems of large influence on pH value of water body, easy crystallization of liquid products, inconvenient storage and transportation, etc. , to achieve the effect of less dosage, not easy to crystallize, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

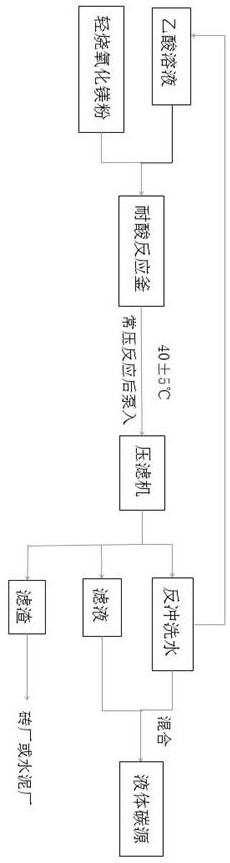

[0023] like figure 1 Shown, a kind of acetic acid-magnesium acetate liquid carbon source production technique comprises the following steps:

[0024] 1) At 40°C and normal pressure, lightly burned magnesium oxide powder was reacted with acetic acid solution for 2 hours to obtain a mixture with a pH value of 4.5~6.0;

[0025] 2) Press filter the mixture in a chamber filter press, and obtain filtrate, backwash water and filter residue after backwashing and air drying;

[0026] 3) Mix backwash water and filtrate at a mass ratio of 0.1:1 to obtain an acetic acid-magnesium acetate liquid carbon source with a pH value of 4.5-6.0.

[0027] Wherein, the light-burned magnesia powder is the burning product of magnesite powder at 400-600°C, its particle size is 100-200 mesh, and the MgO content is 80%; the concentration of the acetic acid solution is 20wt%; the acetic acid solution React with light-burned magnesia powder in an acid-resistant reactor, the mass ratio of MgO in the light-...

Embodiment 2

[0030] like figure 1 Shown, a kind of acetic acid-magnesium acetate liquid carbon source production technique comprises the following steps:

[0031] 1) At 35°C and normal pressure, lightly burned magnesium oxide powder was reacted with acetic acid solution for 3 hours to obtain a mixture with a pH value of 4.5~6.0;

[0032] 2) Press filter the mixture in a chamber filter press, and obtain filtrate, backwash water and filter residue after backwashing and air drying;

[0033] 3) Mix backwash water and filtrate at a mass ratio of 0.3:1 to obtain an acetic acid-magnesium acetate liquid carbon source with a pH value of 4.5-6.0.

[0034] Wherein, the light-burned magnesia powder is the burning product of magnesite powder at 400-600°C, its particle size is 100-200 mesh, and the MgO content is 82%; the concentration of the acetic acid solution is 25wt%; the acetic acid solution React with light-burned magnesia powder in an acid-resistant reactor, the mass ratio of MgO in the light-...

Embodiment 3

[0037] like figure 1 Shown, a kind of acetic acid-magnesium acetate liquid carbon source production technique comprises the following steps:

[0038] 1) At 45°C and normal pressure, lightly burned magnesium oxide powder was reacted with acetic acid solution for 2 hours to obtain a mixture with a pH value of 4.5~6.0;

[0039] 2) Press filter the mixture in a chamber filter press, and obtain filtrate, backwash water and filter residue after backwashing and air drying;

[0040] 3) Mix backwash water and filtrate at a mass ratio of 0.5:1 to obtain an acetic acid-magnesium acetate liquid carbon source with a pH value of 4.5-6.0.

[0041] Wherein, the light-burned magnesia powder is the burning product of magnesite powder at 400-600°C, its particle size is 100-200 mesh, and the MgO content is 80%; the concentration of the acetic acid solution is 30wt%; the acetic acid solution React with light-burned magnesia powder in an acid-resistant reactor, the mass ratio of MgO in the light-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com