Method for enhancing vegetable protein meat flavor by adding sulfur-containing amino acid

A technology for vegetable protein meat and vegetable protein, which is applied in the field of food processing technology, can solve the problems of heavy powder taste, weak aroma, poor embedding effect, etc., and achieves the effects of simple process, high nutritional value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

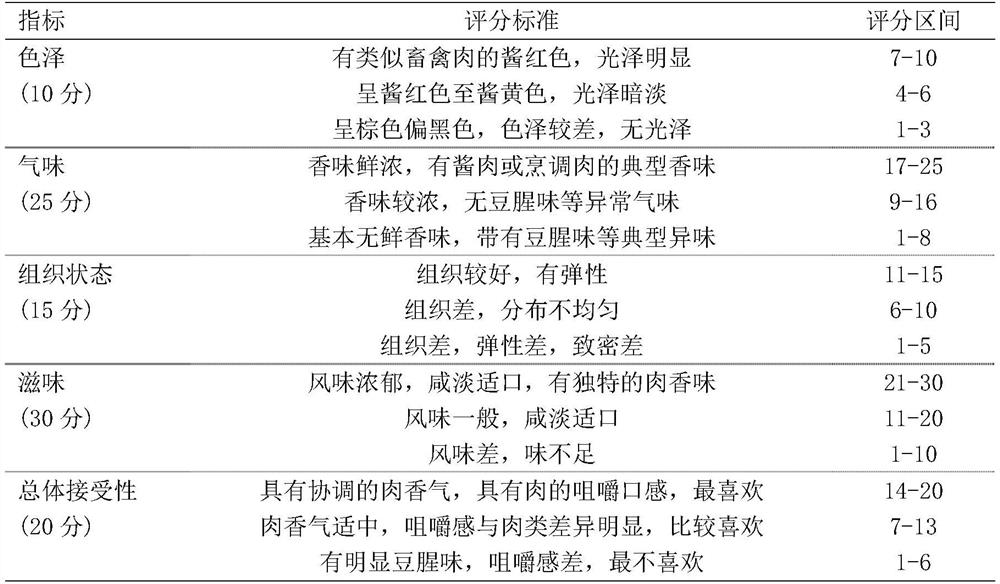

Examples

Embodiment 1

[0033] Step 1: According to mass parts, weigh 8-10 parts of soybean protein powder and 100 parts of water, add soybean protein powder to water, ultrasonic wave for 20 minutes, and then add special enzyme for plant protein hydrolysis and flavor enzyme mixture for 55℃ enzymolysis 4 -6 hours, the mixed enzyme is added according to the metering of 5000U / g soybean protein powder (the enzyme activity of the special enzyme for plant protein hydrolysis is 20000U / g, the enzyme activity of the flavor enzyme is 21000U / g, and the mass ratio is 1:2). After the enzymolysis is completed, heat at 85°C for 15-20 minutes to inactivate the enzyme to obtain an enzymatic hydrolysis solution. The enzymolysis solution was vacuum freeze-dried to obtain a powder.

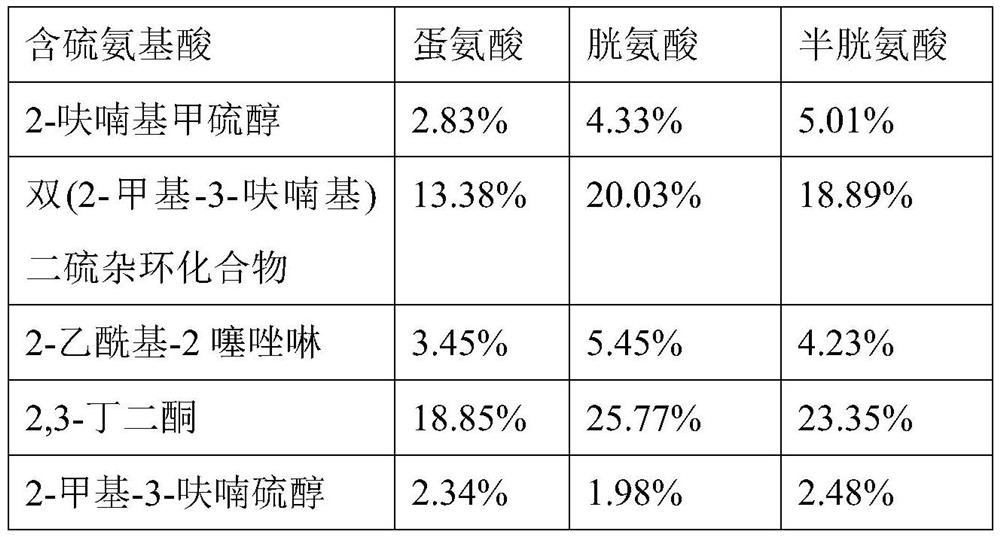

[0034] Step 2: Weigh 6 parts of soybean protease hydrolysate powder, 2 parts of single reducing sugar (glucose), 2 parts of sulfur-containing amino acid (one of methionine, cystine, and cysteine) by weight, and add water The substrate concent...

Embodiment 2

[0038] Step 1: According to mass parts, weigh 8-10 parts of soy protein powder, 100 parts of water, special enzyme for plant protein hydrolysis and flavor enzyme mixture and calculate 5000 U / g (ratio 1:1, 1:2, 2:1 respectively , The enzyme activity of the special enzyme for plant protein hydrolysis is 20000U / g, and the enzyme activity of the flavor enzyme is 21000U / g). The above soybean protein powder is added to water, ultrasonic wave is used to aid dissolution for 20 minutes, then enzymes are added for enzymolysis at 55°C for 4-6 hours, and after enzymolysis is completed, the enzymes are inactivated by heating at 85°C for 15-20 minutes to obtain an enzymatic hydrolysis solution. The enzymolysis solution was vacuum freeze-dried to obtain a powder.

[0039] Step 2: Weigh 6 parts of soybean protease hydrolysate powder, single reducing sugar (glucose) or mixed reducing sugar (by mass ratio, glucose: fructose: maltose=1:1:1) by weight, and 2 parts containing sulfur Amino acid (one ...

Embodiment 3

[0043] Step 1: In parts by weight, 55-60 parts of yeast extract, 20 parts of compound acid hydrolyzed vegetable protein seasoning powder, sulfur-containing amino acids (one or three of methionine, cystine, cysteine) Mix at a mass ratio of 1:1:1) 8 parts, 8 parts salt, 5 parts maltodextrin, 8 parts single reducing sugar (glucose) or mixed reducing sugar (glucose: fructose: maltose=1:1:1), 80-95 parts of water are dissolved and mixed uniformly, placed in a reactor, and reacted at 95°C for 2 hours to obtain Maillard reaction products.

[0044] Step 2: Add 15-20 parts of Maillard reaction product to 100 parts of vegetable protein powder, 2 parts of table salt, 5 parts of vegetable oils and fats, 4 parts of sorghum red, food colorant, and 0.5 parts of food glue, Kodran gum , Adding water to adjust the water content of the material to 50%-55%, placing it in a co-rotating twin-screw extruder to extrude into vegetable protein meat with meat flavor.

[0045] The vegetable protein meat prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com