Preparation and application method of a gypsum composite antifungal agent with waterproof function

A technology of antifungal agent and gypsum, which is applied in the direction of botanical equipment and methods, applications, biocides, etc., can solve problems such as surface mold, gypsum products are not suitable for continued use, and affect durability and aesthetics, so as to improve water resistance. , The preparation method and application method are simple and easy to operate, and the effect of improving water resistance and mildew resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

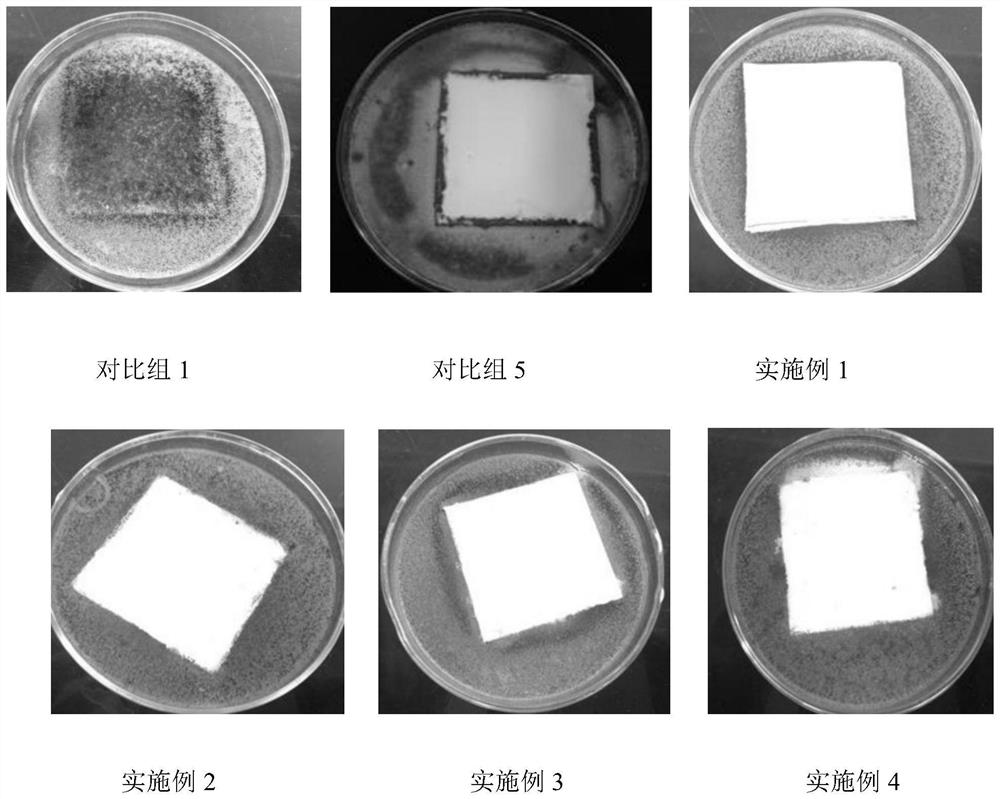

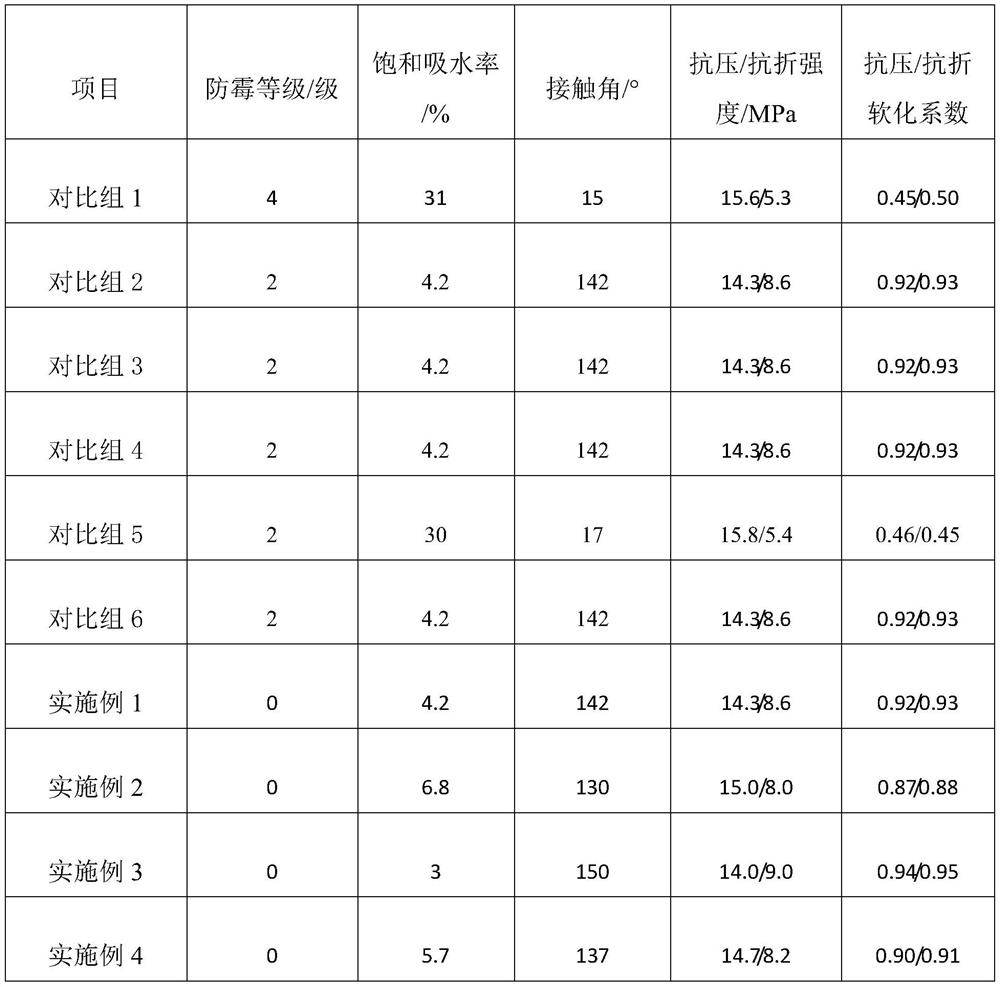

Embodiment 1

[0055] The gypsum composite antifungal agent with waterproof function is composed of the following components in mass fractions: 4 parts of inorganic antibacterial components, 4 parts of chitosan, 5 parts of sodium methyl silicate, 13 parts of silicon acrylic emulsion, and 1.5 parts of sodium bicarbonate 1 part of sodium lauryl sulfate. The inorganic antibacterial components include 1 part of nano-silver, 1 part of borax, 2 parts of nano-titanium dioxide, and 12 parts of montmorillonite.

Embodiment 2

[0057] The gypsum composite antifungal agent with waterproof function is composed of the following components in mass fractions: 3 parts of inorganic antibacterial components, 3 parts of chitosan, 3 parts of sodium methyl silicate, 4 parts of silicon acrylic emulsion, lauryl sulfuric acid Sodium 0.1 part, sodium bicarbonate 0.2 part. The inorganic antibacterial components include 1 part of nano-silver, 1 part of borax, 1 part of nano-titanium dioxide, and 6 parts of montmorillonite.

Embodiment 3

[0059] The gypsum composite antifungal agent with waterproof function is composed of the following components in mass fractions: 8 parts of inorganic antibacterial components, 8 parts of chitosan, 7 parts of sodium methyl silicate, 14 parts of silicon acrylic emulsion, anhydrous dihydrogen phosphate 2 parts sodium, 1 part sodium lauryl sulfate. The inorganic antibacterial components include 2 parts of nano-silver, 1 part of borax, 5 parts of nano-titanium dioxide, and 40 parts of montmorillonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com