A kind of modified bagasse retarder and preparation method thereof

A technology of bagasse and retarder, applied in the field of building materials, can solve problems such as improper handling of bagasse, and achieve the effects of rapid and efficient response, prolonging the setting time, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

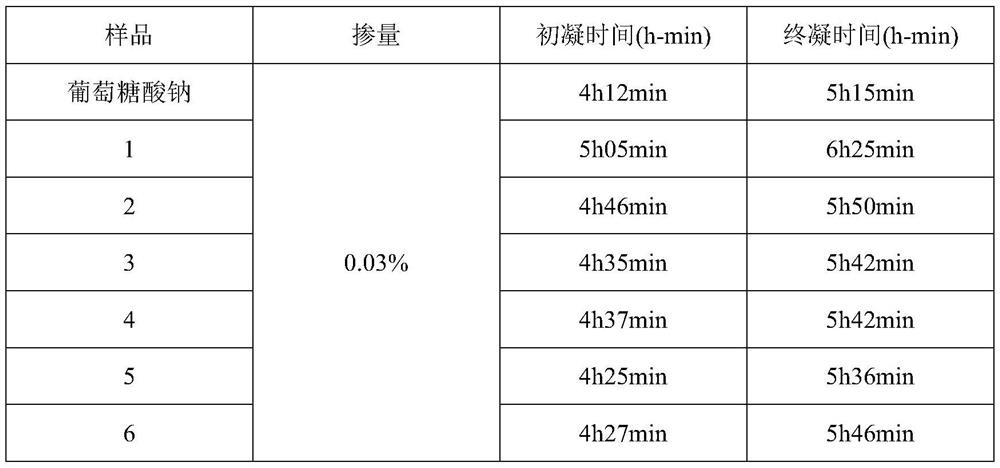

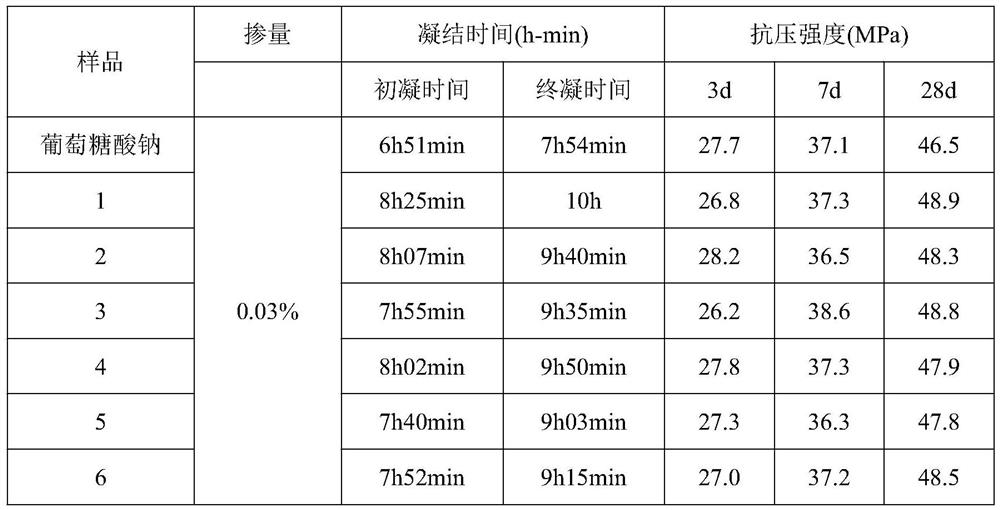

Examples

Embodiment 1

[0026] 1) Pretreatment: Weigh 13.5g of sodium chlorite and 8g of bagasse respectively, mix them evenly, and react at 180° C. for 15min. After the reaction is completed, suction filtration to obtain a filter cake, and the filter cake is repeatedly washed with deionized water. , remove excess sodium chlorite, the color of the filter cake after washing is white, and then the filter cake is placed in an oven to be fully dried, and after drying, it is crushed and ground, and passed through a 100-mesh sieve.

[0027] 2) Acid catalysis: a compound acid is prepared in advance, as follows: 5 g of phosphoric acid, 0.2 g of nitric acid, 0.8 g of sulfuric acid and 2 g of oxalic acid are weighed and dissolved in 50 mL of water. 6 g of pretreated bagasse powder and the above-mentioned composite acid were weighed and put into a flask after stirring evenly, and 1 g of phosphotungstic acid with a concentration of 90% was added thereto as a catalyst. The reaction was carried out under heating i...

Embodiment 2

[0029] 1) Pretreatment: Weigh 15.3g potassium chlorite and 8g bagasse respectively, mix them evenly, react at 170°C for 20min, after the reaction, suction filtration to obtain a filter cake, and the filter cake is repeatedly washed with deionized water to remove For the excess potassium chlorite, the color of the filter cake after washing is white, and then the filter cake is placed in an oven to be fully dried. After drying, it is crushed and ground into powder, and passed through a 100-mesh sieve.

[0030] 2) Acid catalysis: The compound acid was prepared in advance, as follows: 4.5 g of phosphoric acid, 0.5 g of sulfuric acid, 1 g of lactic acid and 1.2 g of nitric acid were weighed and dissolved in 50 mL of water. 6 g of pretreated bagasse powder and the above-mentioned composite acid were weighed and put into a flask after stirring evenly, and 1.2 g of phosphomolybdic acid with a concentration of 90% was added to it as a catalyst. The reaction was carried out under the he...

Embodiment 3

[0032] 1) Pretreatment: Weigh 16.5g potassium sulfite and 8g bagasse respectively, mix them evenly, and react at 160°C for 30min. After the reaction is completed, suction filtration to obtain a filter cake, and the filter cake is repeatedly washed with deionized water. Remove excess potassium sulfite, the color of the filter cake after washing is white, and then the filter cake is placed in an oven to be fully dried, and after drying, it is crushed and ground, and passed through a 100-mesh sieve.

[0033] 2) Acid catalysis: The compound acid is prepared in advance, as follows: 4 g phosphoric acid, 1 g formic acid, 1 g fumaric acid and 2.5 g oxalic acid are weighed and dissolved in 50 mL of water. 6 g of pretreated bagasse powder and the above-mentioned composite acid were weighed and put into a flask after stirring evenly, and 0.8 g of phosphomolybdic acid with a concentration of 90% was added to it as a catalyst. The reaction was carried out under heating in a water bath at 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com