Composite hydrogel, preparation method and application thereof, and method for stimulating and responding to composite hydrogel by multiple factors

A composite hydrogel, stimuli-responsive technology, applied in the field of shape memory polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing the composite hydrogel described in the above technical solution, comprising the following steps:

[0040] Under acidic conditions, PVA, CMC, water, DA and a cross-linking agent are mixed to carry out a cross-linking reaction to obtain the composite hydrogel.

[0041] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in this field.

[0042]In the present invention, the order in which the PVA, CMC, water, DA and crosslinking agent are mixed is preferably: DA and the first part of water are first mixed to obtain the DA aqueous solution; the crosslinking agent and the second part of water are second Mix to obtain a cross-linking agent solution; after mixing the PVA, CMC and the remaining water for the third time, then mix with the DA aqueous solution for the fourth time, and then mix with the cross-linking agent aqueous solution for the fif...

Embodiment 1

[0101] (1) Mix 2gPVA, 0.5gCMC and 20mL of double distilled water at 80°C to obtain a mixed solution, wherein the mass concentration of the PVA solution is 0.10g / mL, and the mass concentration of the CMC solution is 0.025g / mL;

[0102] (2) In the obtained mixed solution, add dropwise a hydrochloric acid solution with a molar concentration of 3.0mol / L at a rate of 30 μL / min, adjust the pH value to 2.0, and add 2 mL of hydrochloric acid solution with a molar concentration of 0.2mol / L in a nitrogen atmosphere. DA solution, magnetically stirred for 30min, after mixing evenly, then add 0.5mL glutaraldehyde solution with a mass concentration of 5%, after mixing evenly, pour it into a hydrogel prefabricated mold, and carry out cross-linking in a water bath at 40°C After 20 minutes of reaction, the DA / CMC / PVA composite hydrogel was obtained.

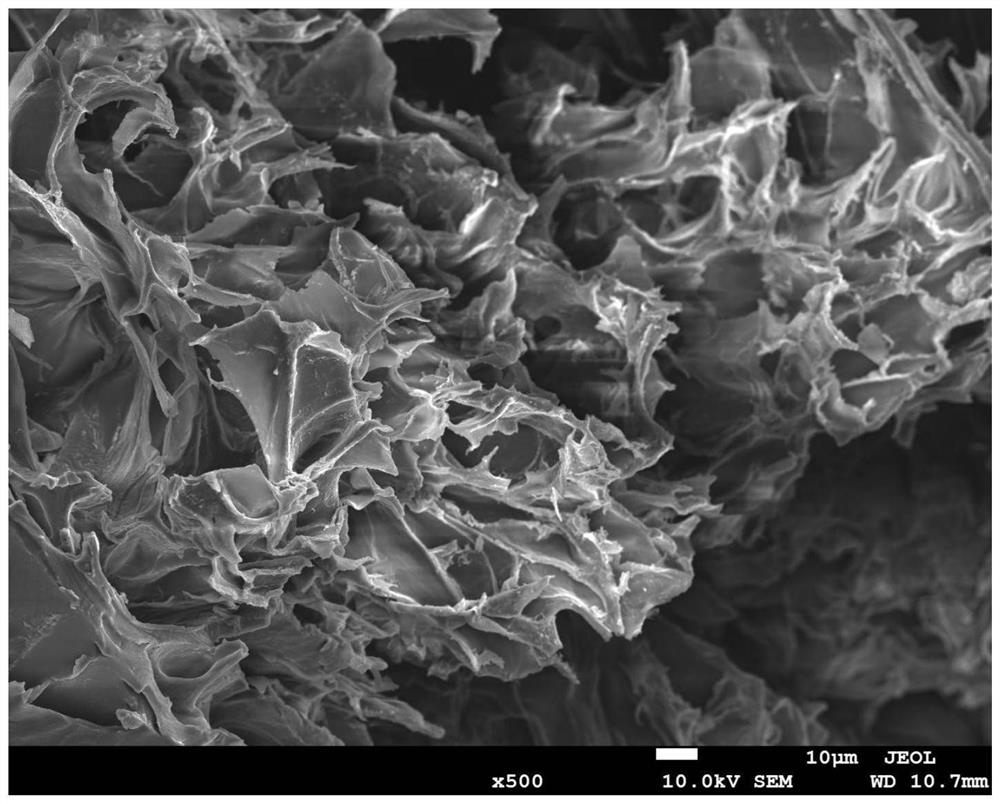

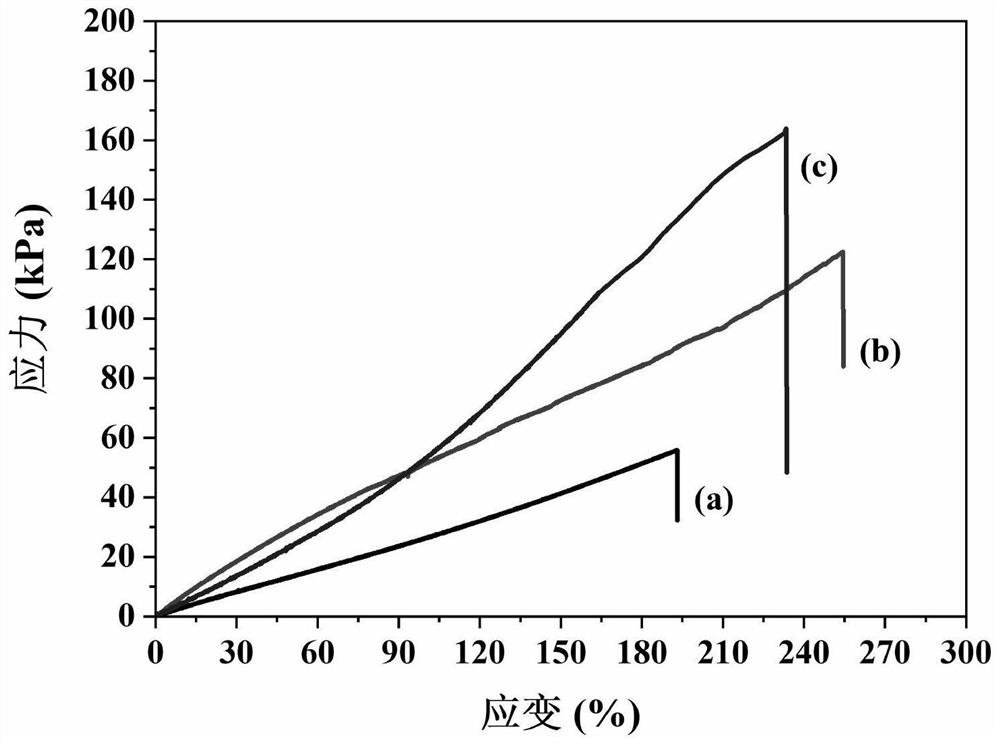

[0103] figure 1It is the HRSEM image of the DA / CMC / PVA composite hydrogel prepared in Example 1. It can be seen from the figure that the surfac...

Embodiment 2

[0118] (1) 3gPVA, 1gCMC and 20mL90°C double distilled water are mixed to obtain a mixed solution, wherein the mass concentration of the PVA solution is 0.15g / mL, and the mass concentration of the CMC solution is 0.05g / mL;

[0119] (1) In the obtained mixed solution, add dropwise a hydrochloric acid solution with a molar concentration of 2.0 mol / L at a rate of 30 μL / min to adjust the pH value to 3.0, and add 2 mL of a hydrochloric acid solution with a molar concentration of 0.8 mol / L in a nitrogen atmosphere. DA solution, magnetically stirred for 30min, after mixing evenly, then add 0.5mL glutaraldehyde solution with a concentration of 10%, after mixing evenly, pour it into the hydrogel prefabricated mold, and carry out the cross-linking reaction under the condition of 60°C water bath , after 20min, the DA / CMC / PVA composite hydrogel was obtained;

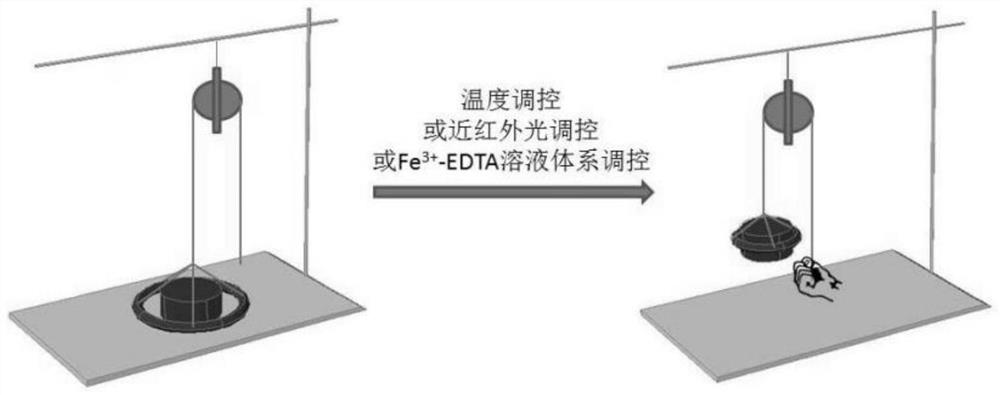

[0120] Shape memory and recovery experiments

[0121] Fe 3+ stimulus response

[0122] 5-10g of the DA / CMC / PVA composite hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com