High-temperature high-strength wear-resistant self-lubricating material and preparation method thereof

A self-lubricating material and high-temperature technology, which is applied in the field of metal material manufacturing and powder metallurgy, can solve the problems of reducing the matching accuracy, service life and reliability of parts, reducing the service life of the engine, system safety, and increasing energy consumption. The effect of particle size reduction, good density, and microhardness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

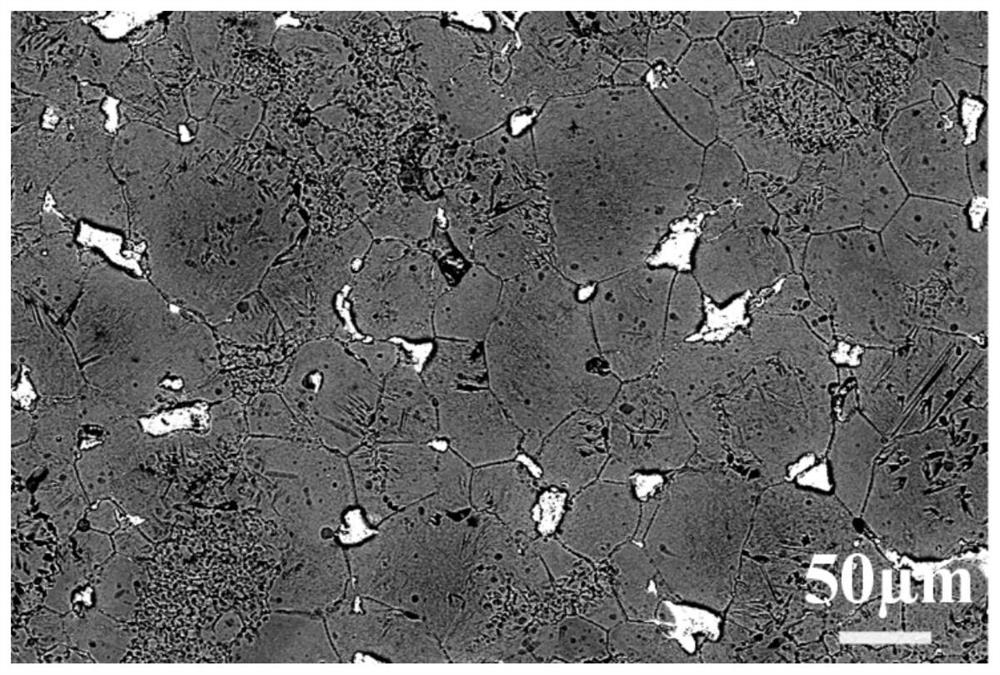

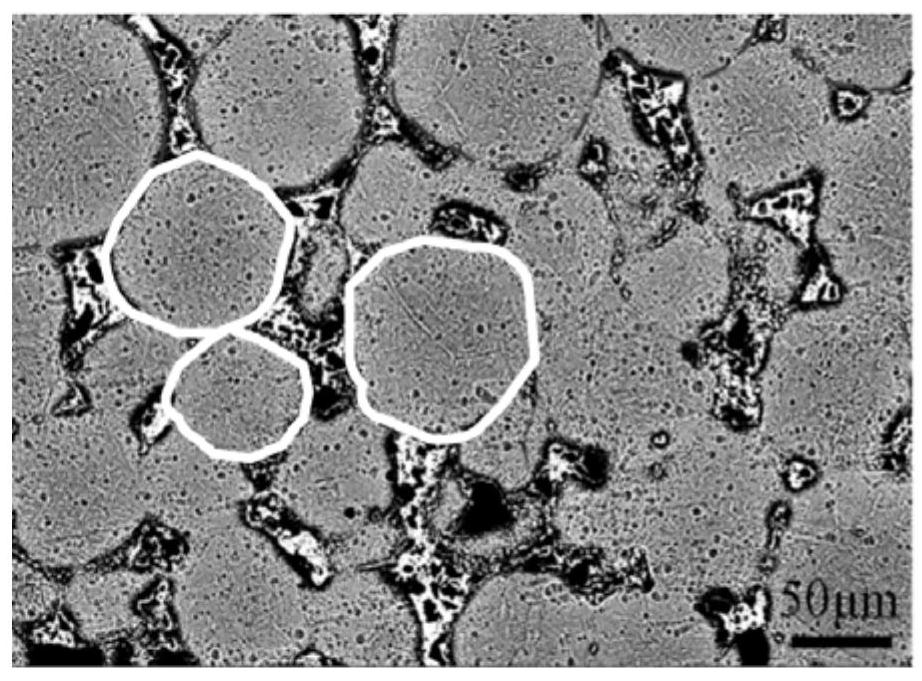

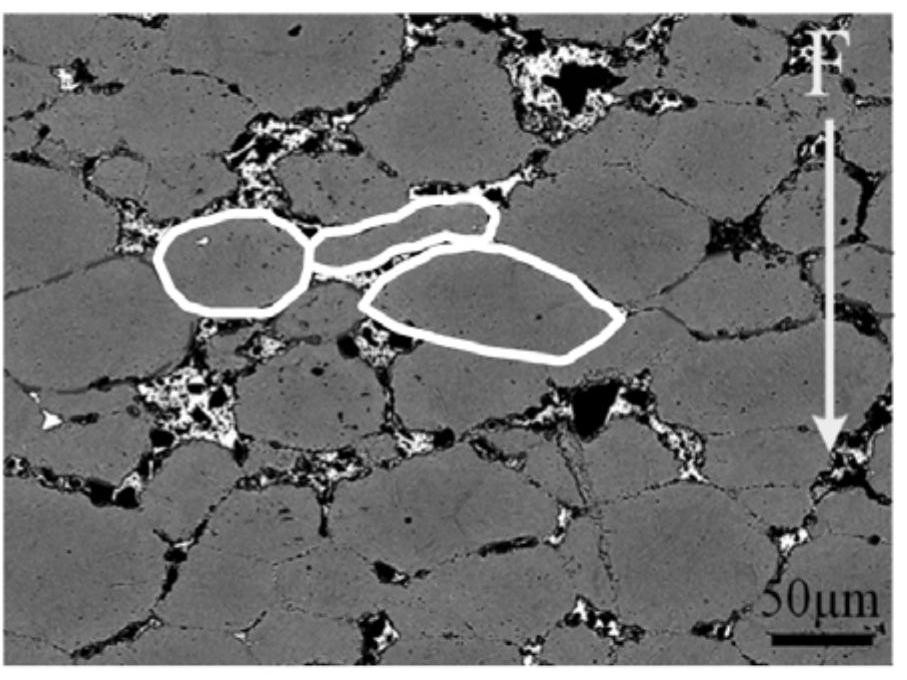

Image

Examples

preparation example Construction

[0036] A method for preparing a high-temperature, high-strength wear-resistant self-lubricating material of the present invention, the specific steps are as follows:

[0037] (1) Argon gas is passed to the vacuum glove box, and Ag powder and TiB are weighed in the vacuum glove box 2 Powder and Ti 2 AlNb spherical pre-alloyed powder, in mass percentage: the mass of Ag powder is Ag powder, TiB 2 Powder and Ti 2 1% to 15% of the total mass of AlNb spherical pre-alloyed powder, TiB 2 The mass is Ag powder, TiB 2 Powder and Ti 2 1% to 7% of AlNb spherical pre-alloyed powder, and the argon atmosphere is always kept in the glove box during the weighing process; among them, the particle size of Ag powder is 1 μm to 2 μm; TiB 2 The particle size of powder is 3μm~5μm; Ti 2 AlNb pre-alloyed powder is a spherical powder prepared by gas atomization, with a particle size of 80 μm to 100 μm;

[0038] The weighed Ag powder, TiB 2 Powder and Ti 2 The AlNb spherical pre-alloyed powder ...

Embodiment 1

[0045] The preparation method of the high-temperature high-strength wear-resistant self-lubricating material of this embodiment is carried out according to the following steps:

[0046] (1) By mass percentage, the content of Ag powder is Ag powder, TiB 2 Powder and Ti 2 15% of the total mass of AlNb spherical pre-alloyed powder, TiB 2 The powder content is Ag powder, TiB 2 Powder and Ti 2 1% of the total mass of AlNb spherical pre-alloyed powder, weighing Ag powder and TiB in a glove box in an argon atmosphere state 2 Powder and Ti 2 AlNb pre-alloyed powder. Place the weighed powder into an anhydrous ethanol solution for ultrasonic dispersion in a 35°C water bath for 3 hours to make the powder into a slurry-like material;

[0047] (2) Put the slurry-like material prepared in step (1) together with stainless steel grinding balls into the ball milling tank. During this process, the argon atmosphere is always maintained in the glove box, and the ball-to-material ratio is 6:...

Embodiment 2

[0054] The preparation method of the high-temperature high-strength wear-resistant self-lubricating material of this embodiment is carried out according to the following steps:

[0055] (1) By mass percentage, the content of Ag powder is Ag powder, TiB 2 Powder and Ti 2 10% of the total mass of AlNb spherical pre-alloyed powder, TiB 2 The powder content is Ag powder, TiB 2 Powder and Ti 2 2% of the total mass of AlNb spherical pre-alloyed powder, weighing Ag powder and TiB in a glove box in an argon atmosphere state 2 Powder and Ti 2 AlNb pre-alloyed powder. Place the weighed powder into an anhydrous ethanol solution for ultrasonic dispersion in a water bath at 35°C for 6 hours, so that the powder becomes a slurry-like material;

[0056] (2) Put the slurry-like material prepared in step (1) together with stainless steel grinding balls into the ball milling tank. During this process, the argon atmosphere is always maintained in the glove box, and the ball-to-material rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com