Preparation method of potassium hydroxide modified magnetic corncob biochar composite material applied to removal of imidacloprid in water

A potassium hydroxide and composite material technology, applied in the directions of alkali metal oxides/hydroxides, chemical instruments and methods, water pollutants, etc., can solve problems such as large-scale application limitations, poor adsorption performance, etc., and achieve resource utilization Utilize, realize the effect of recycling and regeneration, reduce ecological risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0048] Example 1: Put the corncobs in a blast oven at 70°C and dry them to constant weight, then transfer them to a high-temperature tube furnace (N 2 The flow rate is 1.0L / min, the heating rate is 10°C / min), pyrolyzed at 400°C for 120min, and ground through a 100-mesh sieve to obtain corncob biochar CBC. Mix CBC (5.0g in mass) and KOH (5.0g in mass) and transfer them into a high-temperature tube furnace (the pyrolysis conditions are the same as the preparation process of CBC), grind them through a 100-mesh sieve, and obtain potassium hydroxide modified Corn cob biochar KOH-CBC. Add 150mL of CBC with a mass of 5.0g to dissolve FeCl 3 ·6H 2 O (mass 2g) and ZnCl 2 (2g) in the solution, at 25 DEG C and rotating speed be the constant temperature shaking box of 150rmp / min shaking 1440min, be placed in 70 DEG C of blast ovens and dry to constant weight, then change over to pyrolysis in the high-temperature tube furnace ( The pyrolysis conditions are the same as the preparation p...

example 2

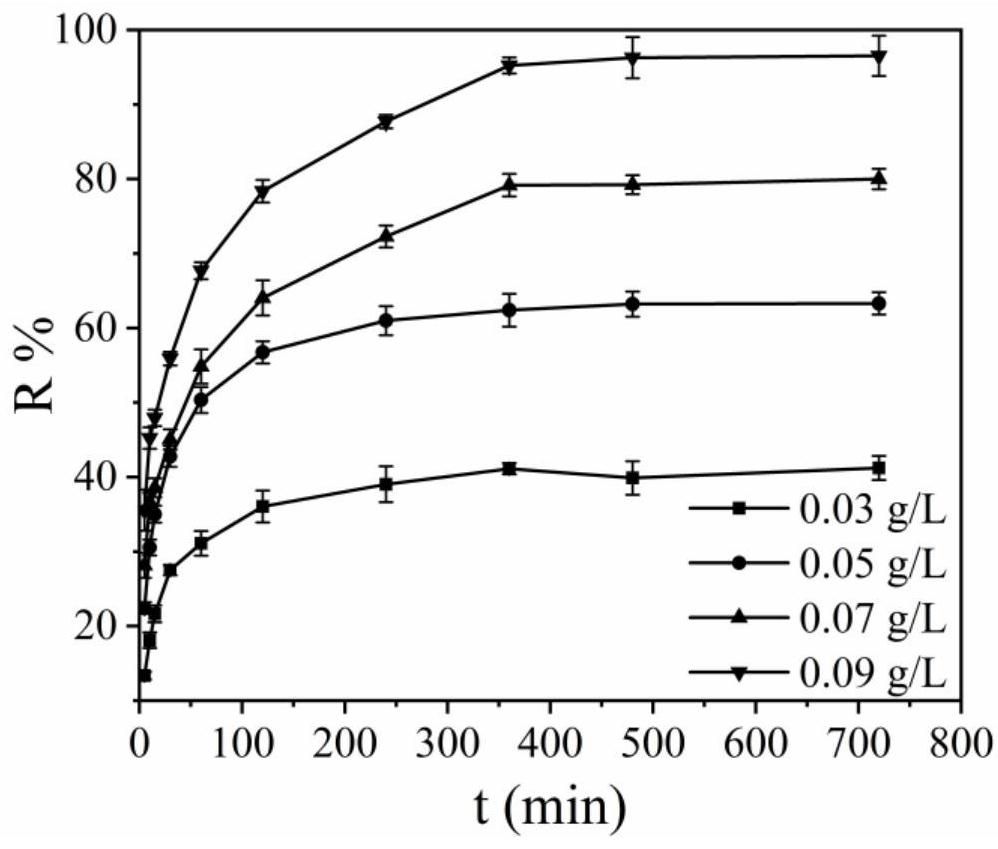

[0049] Example 2: 0.03-0.09g / L of KOH+Fe / Zn-CBC was added into the imidacloprid solution with a volume of 100mL and a concentration of 20mg / L, and the adsorption experiment was carried out in a constant temperature shaking box (150rmp / min) at 25°C. Sampling at the set time (5-720min), measure the absorbance of imidacloprid at λ=270nm with a UV photometer, and calculate the removal rate of imidacloprid at different times.

[0050] It can be seen from Figure 1(a) that KOH+Fe / Zn-CBC can achieve efficient removal of imidacloprid at the initial stage of the experiment, and the removal rate of imidacloprid increases with the increase of adsorbent dosage and reaction time. When the dosage is 0.09g / L, the removal rate of imidacloprid can reach 96.54% in 720min.

example 3

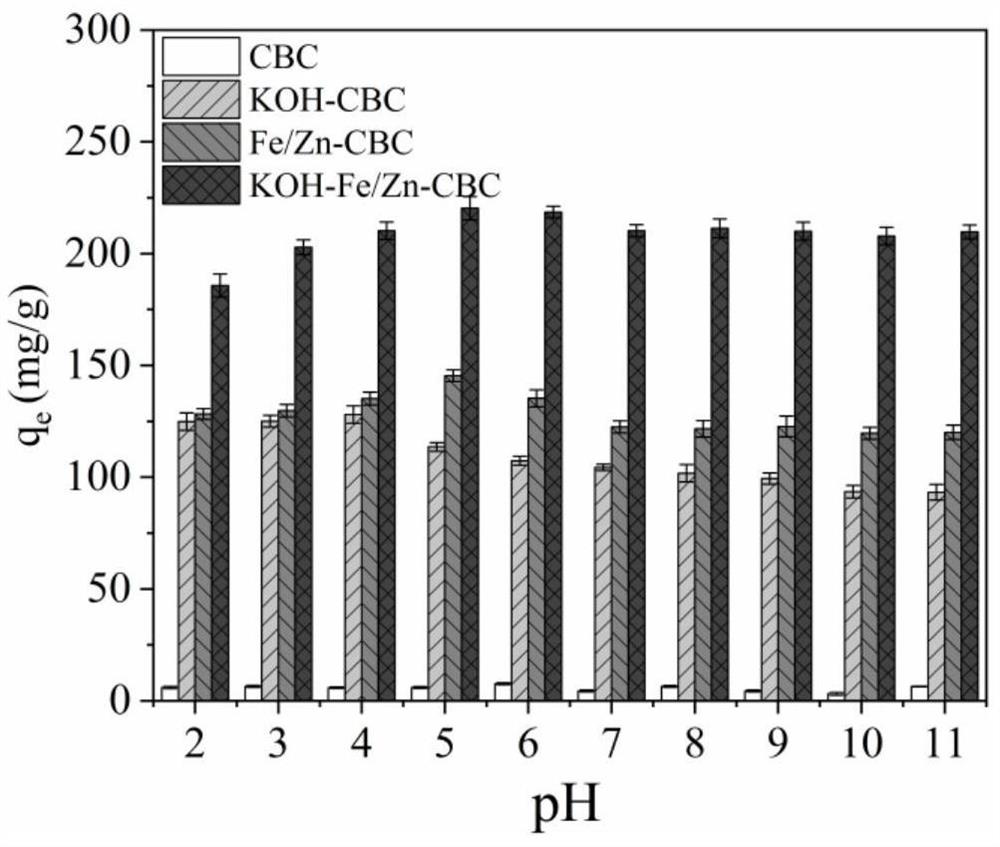

[0051] Example 3: Adding CBC, KOH-CBC, Fe / Zn-CBC and KOH+Fe / Zn-CBC with a dose of 0.07g / L to an imidacloprid solution with a volume of 100mL and a concentration of 20mg / L and pH=2-11 (Use 0.1 mol / L HCl and NaOH to adjust the pH of the solution), put it in a constant temperature shaking box (150rmp / min) at 25°C for adsorption experiments, and when the adsorption is balanced, use a UV photometer to measure imidacloprid at λ=270nm The absorbance of the four biochars was calculated to calculate the adsorption capacity of the four biochars.

[0052] It can be seen from Figure 1(b) that the adsorption capacity of imidacloprid by the adsorbents CBC, KOH-CBC, Fe / Zn-CBC and KOH+Fe / Zn-CBC is not greatly affected by the pH of the solution, but the four biochars are all at pH =5-6, the adsorption capacity of imidacloprid is the strongest, and the maximum adsorption capacity of KOH+Fe / Zn-CBC to imidacloprid can reach 220.3mg / g when pH=5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com