Local additive manufacturing method of bimetal composite oil well pipe screwed joint

A threaded joint and additive manufacturing technology, which is applied in the field of oil drilling and production equipment, can solve problems such as small size, ensure material strength, avoid corrosion and leakage later, and realize structural integrity of threaded joints and high-pressure gas tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

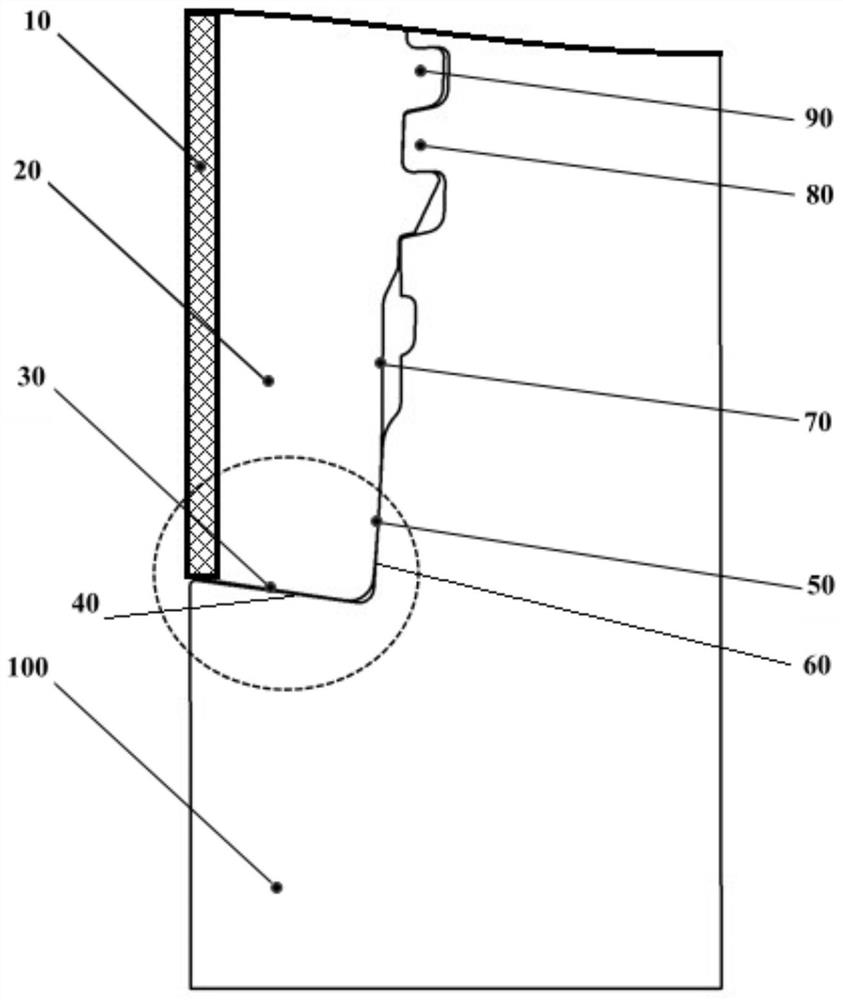

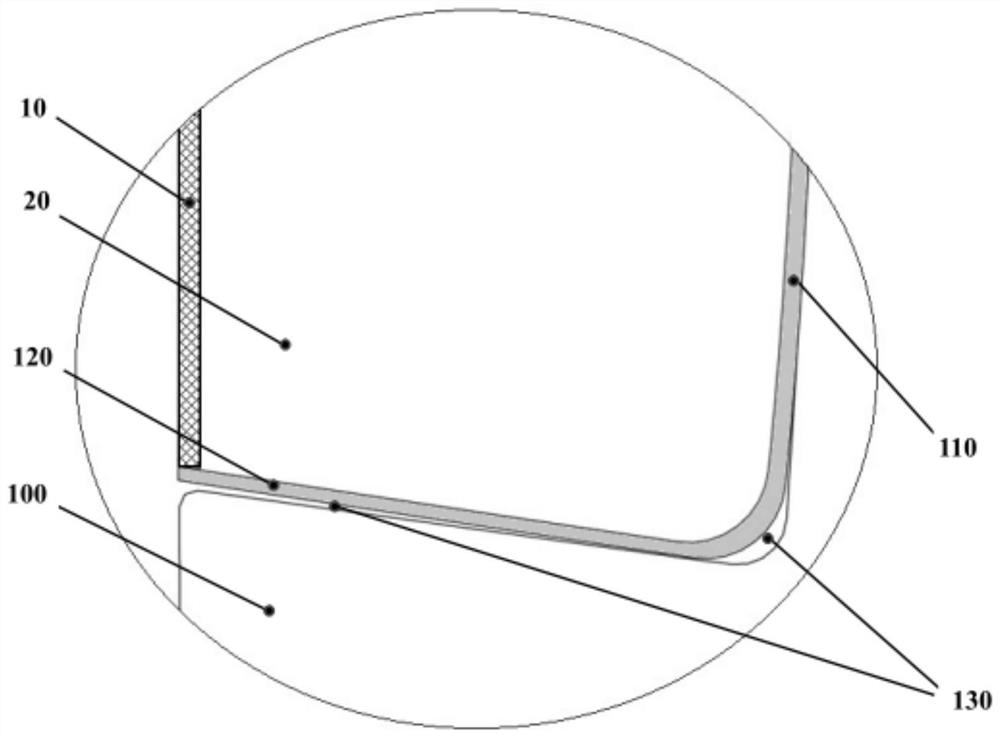

[0032]Embodiment 1: Select nickel-based alloy powder, the nickel-based alloy powder has a particle size of about 75-100 μm spherical nickel-based powder, protected by argon to ensure that the oxygen content is less than 50 ppm. The laser power is 1.0kW~1.2kW, the scanning speed is 5mm / s, the laser spot diameter is 2mm, the synchronous powder feeding speed is 0.4g / min-0.7g / min, and the multi-pass overlapping rate is 40%; the additive manufacturing process The scanning path is set according to the topography of the sealing surface 50 and the torque shoulder surface 30, and the corrosion-resistant alloy layers are accumulated layer by layer. The powder feeding rate used in the first pass is about 0.7 / min, and the accumulation thickness of a single pass is about 0.2mm, so as to reduce the dilution rate. The powder feeding rate used in the rest of the passes is about 0.4g / min, and the thickness of the accumulated material in a single pass is less than 0.1mm, and the average total t...

Embodiment 2

[0033] Embodiment 2: Select nickel-based alloy powder, nickel-based spherical powder with a particle size of 75-100 μm, and protect it with argon to ensure that the oxygen content is less than 50 ppm. The laser power is 1.0kW~1.2kW, the scanning speed is 5mm / s, the laser spot diameter is 2mm, the synchronous powder feeding speed is 0.4g / min-0.7g / min, and the multi-pass overlapping rate is 40%; the additive manufacturing process Set the scanning path according to the shape of the sealing surface 50 and the torque shoulder surface 30, and accumulate the corrosion-resistant alloy layer layer by layer; the powder feeding rate used in the first pass is 0.7 / min, and the single-pass accumulation thickness is 0.2mm, reducing the dilution rate . The powder feeding rate used in the rest of the passes is 0.4g / min, the thickness of the single-pass accumulation material is less than 0.5mm, and the average total accumulation thickness is 1.5mm through the multi-pass processing.

Embodiment 3

[0034] Embodiment 3: Select nickel-based alloy powder, nickel-based spherical powder with a particle size of 75-100 μm, and protect it with argon to ensure that the oxygen content is less than 50 ppm. The laser power is 1.0kW~1.2kW, the scanning speed is 5mm / s, the laser spot diameter is 2mm, the synchronous powder feeding speed is 0.4g / min-0.7g / min, and the multi-pass overlapping rate is 40%; the additive manufacturing process Set the scanning path according to the shape of the sealing surface 50 and the torque shoulder surface 30, and accumulate the corrosion-resistant alloy layer layer by layer; the powder feeding rate used in the first pass is 0.7 / min, and the single-pass accumulation thickness is 0.2mm, reducing the dilution rate . The powder feeding rate used in the rest of the passes is 0.5g / min, the thickness of the single-pass accumulation material is 0.08mm, and the average total accumulation thickness is 2.0mm through the multi-pass processing process.

[0035] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com