Polishing-free water-based intermediate coating for rail transit and preparation method thereof

A technology for rail transit and coatings, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor adhesion, reduce waste, improve production efficiency, and maintain service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

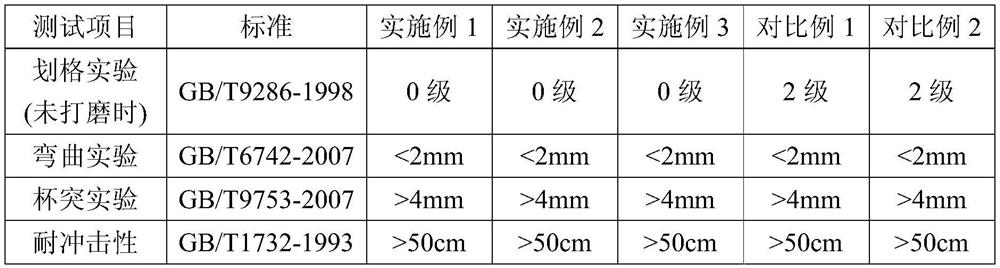

Examples

Embodiment 1

[0030] A non-grinding water-based intermediate coating for rail transit, the coating includes component A and component B, the weight ratio of component A and component B is 4:1, and the component A includes waterborne polyurethane resin 20 parts, 15 parts of hydroxyacrylic acid dispersion, 0.3 parts of non-silicon high polymer defoamer, 5 parts of pigment, 5 parts of filler, 3 parts of coalescent, 0.2 part of anti-settling agent, 0.2 part of thickener, deionized 5 parts of water, of which,

[0031] The waterborne polyurethane resin is Covestro 2457 resin,

[0032] The hydroxyacrylic acid dispersion is Wanhua 2042N,

[0033] The non-silicon high polymer defoamer is BYK011,

[0034] The pigment is an inorganic pigment,

[0035] The filler is barium sulfate,

[0036] The film-forming aid is ethylene glycol butyl ether,

[0037] The anti-settling agent is bentonite anti-settling agent,

[0038] The thickener is a polyurethane associative thickener;

[0039] In the componen...

Embodiment 2

[0046] A non-grinding water-based intermediate coating for rail transit, the coating includes component A and component B, the weight ratio of component A and component B is 4:1, and the component A includes waterborne polyurethane resin 40 parts, 25 parts of hydroxyacrylic acid dispersion, 0.5 parts of amine neutralizer, 0.8 parts of non-silicon high polymer defoamer, 20 parts of pigment, 40 parts of filler, 10 parts of coalescent, 1 part of anti-settling agent, 1 part of thickener, 20 parts of deionized water, wherein,

[0047] The waterborne polyurethane resin is Covestro 2457 resin,

[0048]The hydroxyacrylic acid dispersion is Wanhua 2042N,

[0049] The non-silicon high polymer defoamer is BYK012,

[0050] The pigment is an organic pigment,

[0051] The filler is talcum powder,

[0052] The film-forming aid is diethylene glycol methyl ether,

[0053] The anti-settling agent is bentonite anti-settling agent,

[0054] The thickener is a polyurethane associative thicke...

Embodiment 3

[0062] A non-grinding water-based intermediate coating for rail transit, the coating includes component A and component B, the weight ratio of component A and component B is 4:1, and the component A includes waterborne polyurethane resin 28 parts, 22 parts of hydroxyacrylic acid dispersion, 0.3 parts of amine neutralizer, 0.5 parts of non-silicon high polymer defoamer, 10 parts of pigment, 20 parts of filler, 8 parts of coalescence aid, 0.5 part of anti-settling agent, 0.5 parts of thickener, 15 parts of deionized water, wherein,

[0063] The waterborne polyurethane resin is Covestro 2457 resin,

[0064] The hydroxyacrylic acid dispersion is Wanhua 2042N,

[0065] The non-silicon high polymer defoamer is BYK012 and BYK015 with a weight ratio of 1:1,

[0066] The pigment is carbon black,

[0067] The filler is sericite,

[0068] The film-forming aid is diethylene glycol methyl ether and alcohol ester-12 with a weight ratio of 1:2,

[0069] The anti-settling agent is benton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com