Polyimide modified epoxy resin composite conductive adhesive and preparation method thereof

A composite conductive and epoxy resin technology, applied in the direction of epoxy resin glue, conductive adhesive, adhesive, etc., can solve the problems of high water absorption, low mechanical strength, poor high temperature resistance, etc., to improve flexibility, Excellent overall performance and enhanced flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the composite conductive agent will be described in detail below.

[0032] The operation of each step will be described in detail below.

[0033] (1) Soluble active polyimide

[0034] In the present invention, the preparation of the soluble reactive polyimide can be carried out by methods known in the art, preferably a two-step method.

[0035] According to some embodiments of the present invention, the preparation of the solvent-reactive polyimide can be carried out according to the method described in CN1927908A.

[0036] The solvent-reactive polyimide is obtained by chemical dehydration using a two-step process.

[0037] Specifically, the preparation of the soluble active polyimide includes:

[0038] After reacting long side chain diamine, hydroxyl diamine and alicyclic dianhydride in a strong polar aprotic organic solvent under nitrogen protection at 0°C-30°C for 3-12 hours, transparent and viscous polyhydroxyl Amic acid solution, where...

Embodiment approach

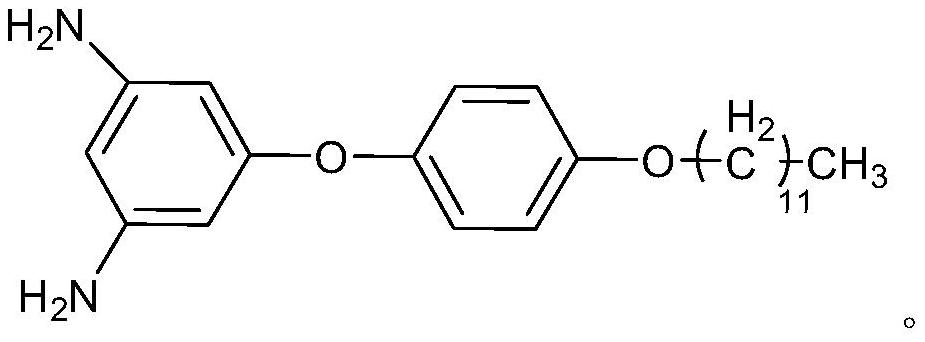

[0042] According to some embodiments of the present invention, the long side chain diamine monomer is 5-(4-(dodecyloxy)phenoxy)benzene-1,3-diamine (DPBDA), the structure of which is :

[0043]

[0044] According to some embodiments of the present invention, the hydroxydiamine is 4,6-diamino-1,3-resorcinol (DADHB), 2,2-bis(3-amino-4-hydroxyl-1,1 , 13,3,3-hexafluoropropane (BAHPFP), 2,2-bis(3-amino-4-hydroxyphenyl)propane (BAHPP), 3,3'-diamine-4,4-dihydroxydi Phenyl ether (DAHDPE), 3,3'-diamino-4,4-dihydroxydiphenyl sulfide (DAHDPS), 3,3'-diamino-4,4-dihydroxybiphenyl (DAOHBP), 3, At least one of 3'-diamino-4,4-dihydroxydiphenylmethane (DAHDPM) and 3,3'-diamino-4,4-dihydroxydiphenylsulfone (DAHDPS).

[0045] In some embodiments, the hydroxydiamine is 4,6-diamino-1,3-resorcinol, 2,2-bis(3-amino-4-hydroxyl-1,1,13,3, 3-hexafluoropropane, 2,2-bis(3-amino-4-hydroxyphenyl)propane, 3,3'-diamino-4,4-dihydroxydiphenyl ether, 3,3'-diamino- 4,4-dihydroxydiphenylsulfide, 3,3'-diamino...

Embodiment 1-9

[0085] According to the amount of each component in Table 3, in terms of mass percentage, bisphenol A type epoxy resin, alicyclic epoxy resin 3,4-epoxycyclohexylcarboxylate-3',4'-epoxy Cyclohexyl methyl ester and soluble agent active polyimide are added into the organic solvent, stirred and dissolved at 50°C, then added with amine curing agent and accelerator and stirred and mixed, finally added coupling agent and conductive filler, continued to stir and mix evenly, and obtained Composite conductive adhesive.

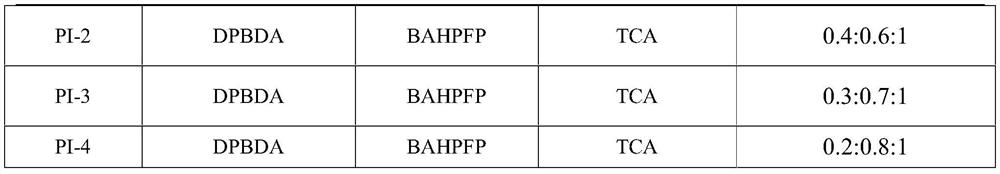

[0086] table 3

[0087]

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com