Processing equipment for solid oxide fuel cell

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problem of failure fuel cell startup heat energy consumption, prone to carbon deposition cells, mismatched hydrogen production rate, etc. problems, to maximize energy utilization, reduce anode carbon deposition, and reduce carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The catalyst used in the processing equipment of the solid oxide fuel cell of the present invention is prepared according to the following preparations:

[0032] (1) Dissolve 8mmol cerium nitrate hexahydrate and 2.5mmol nickel nitrate hexahydrate in 40ml deionized water, and simultaneously dissolve 480mmol sodium hydroxide in 40ml deionized water, then mix and stir the above two solutions to obtain the first product; wherein , the stirring temperature is 25° C., the stirring speed is 500 r / min, and the stirring time is 30 min.

[0033] (2) Mix block foam ceramics with the first product, perform hydrothermal reaction, and then wash and dry to obtain the second product; wherein, the temperature of the hydrothermal reaction is 100°C, and the hydrothermal time is 24h; the used The preparation method of the block foam ceramics is prepared by slurrying and sintering the polyurethane sponge of 40PPI twice, wherein, the slurry for slurrying is 300g, alumina powder, 0.2g dispers...

Embodiment 2

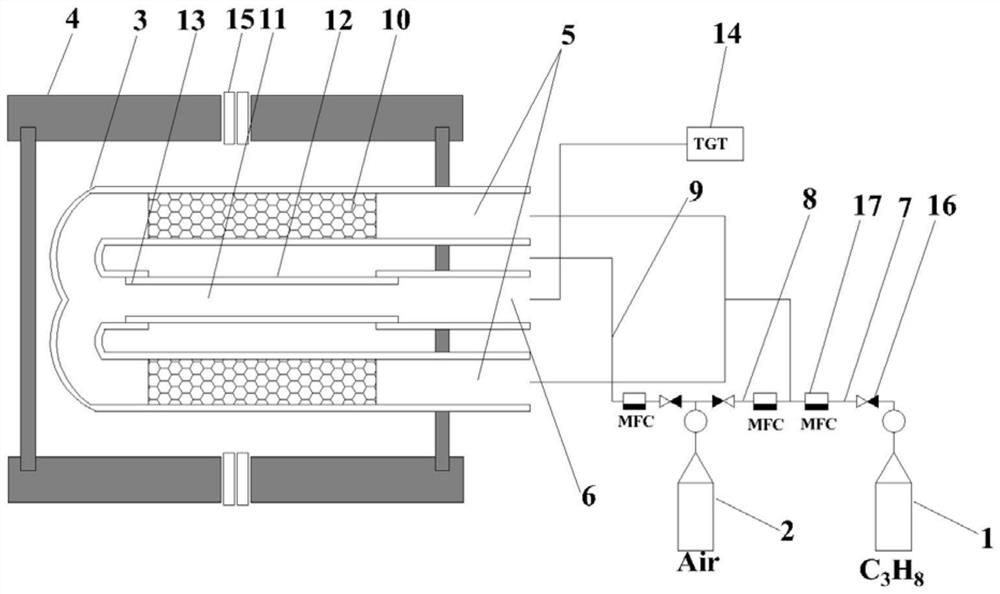

[0038] Processing equipment for solid oxide fuel cell tubes, such as figure 2 As shown, it includes a propane tank 1, an air tank 2, a quartz glass tube 3 and a cylindrical tube furnace 4;

[0039] The quartz glass tube is in the shape of m and has 3 openings in total. The openings at both ends are the inlet 5, the middle opening is the outlet 6, and the middle outlet section of the quartz glass tube has 2 gaps;

[0040]The air inlet pipe 7 of the propane tank and the first air inlet pipe 8 of the air tank are connected to two inlets of the quartz glass tube after they merge, and the second air inlet pipe 9 of the air tank communicates with the inner cavity of the cylindrical tube furnace, and the quartz glass tube is placed Inside the cylindrical tube furnace, the inlet and outlet of the quartz glass tube are installed on the side wall of the cylindrical tube furnace, the catalyst 10 is placed inside the inlet section at both ends of the quartz glass tube, and the solid oxid...

Embodiment 3

[0045] Utilize the processing equipment of the solid oxide fuel cell tube described in embodiment 2, and the catalyst obtained in embodiment 1 to start the fuel cell:

[0046] In the first step, the catalyst obtained in Example 1 is placed in a quartz glass tube, the gas path is connected, and then the cylindrical tube furnace is heated, and the temperature is detected by a temperature detector. When the temperature reaches the starting temperature of the catalyst and the battery, it is generally 600- 700°C.

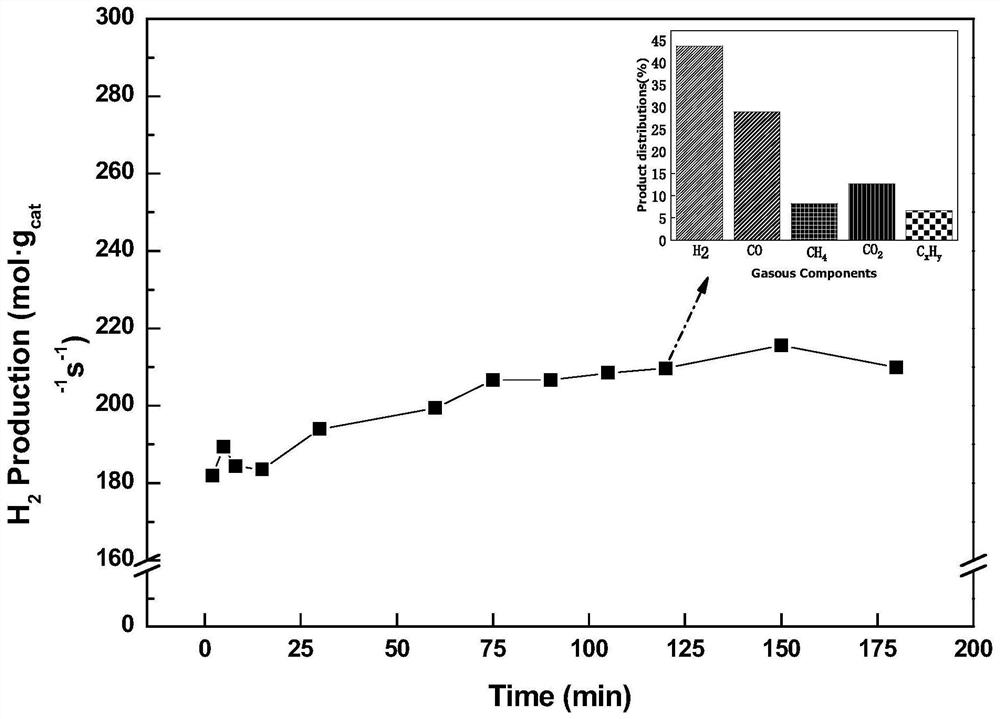

[0047] In the second step, open the propane tank first, then open the air tank, and control the flow through the rotameter respectively. The mixed gas A of 40 sccm of propane and 285 sccm of air enters the quartz glass, and the partial oxidation reforming reaction is carried out under the catalytic action of the catalyst. Hydrogen gas is produced.

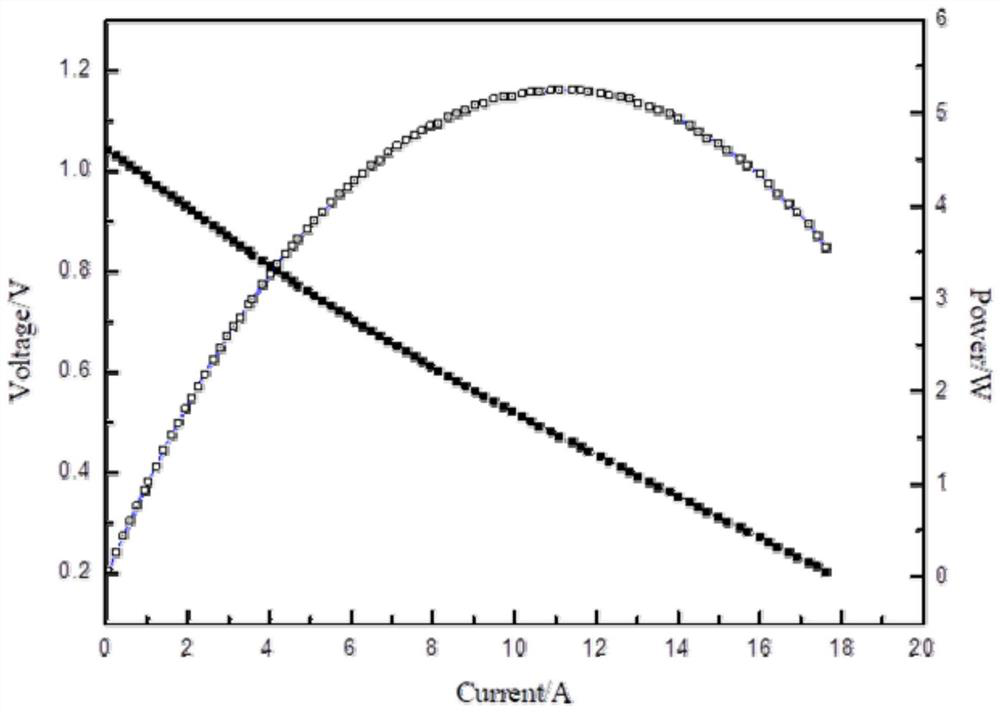

[0048] The third step is to adjust the flow control valve of the air tank, so that the dry air enters the interior of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com