Collagen peptide-containing polycaprolactone microsphere filler and preparation method therefor

A technology of collagen peptide and polycaprolactone, which is applied in skin care preparations, microcapsules, capsule delivery, etc., can solve the problems of low skin penetration and low stability, achieve high tissue repair properties, and improve wrinkles , The effect of rapid collagen formation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] As a specific example of the preparation method of the collagen peptide-containing polycaprolactone microspheres of the present disclosure, such a preparation method includes the following steps: (a) dissolving polycaprolactone in the first solvent and dissolving the collagen peptide dissolving in a second solvent to prepare respective solutions, and then uniformly mixing the two solutions to prepare a single solution, to prepare a dispersed phase; (b) by mixing said dispersed phase with an aqueous solution (continuous phase) containing a surfactant to prepare an emulsion; (c) by extracting an organic solvent from the dispersed phase in said emulsion prepared in step (b) into the continuous phase and evaporating to form microspheres; and (d) from step (c) The continuous phase recovers the microspheres to prepare polycaprolactone microspheres containing collagen peptides.

[0032] In step (a), the polycaprolactone preferably has an intrinsic viscosity in the range of 0.1...

Embodiment 1

[0052] Example 1: Preparation of Microspheres Encapsulated with Collagen Peptides

[0053] By completely dissolving 9.99 g of biocompatible polymer Purasorb PC 04 (manufacturer: Corbion, Netherlands) and 0.01 g of palmitoyl-KTTKS (manufacturer: Incospharm, Korea) in 39.96 g of dichloromethane (manufacturer: JT Baker , USA) and 2.02 mL of methanol (manufacturer: Sigma Aldrich, USA), and then mix the two solutions to prepare a dispersed phase. A 2 w / v% polyvinyl alcohol aqueous solution (viscosity: 4.8 to 5.8 mPa·s) was used as the continuous phase, and 3200 mL of the continuous phase was supplied to an emulsification device equipped with a 10 μm diameter porous membrane while injecting the prepared dispersion phase to prepare microspheres. The prepared microsphere suspension was placed in a preparation container and stirred at a speed of 150 rpm. The temperature of the membrane emulsification device and the preparation vessel was maintained at 25°C.

[0054]When the inject...

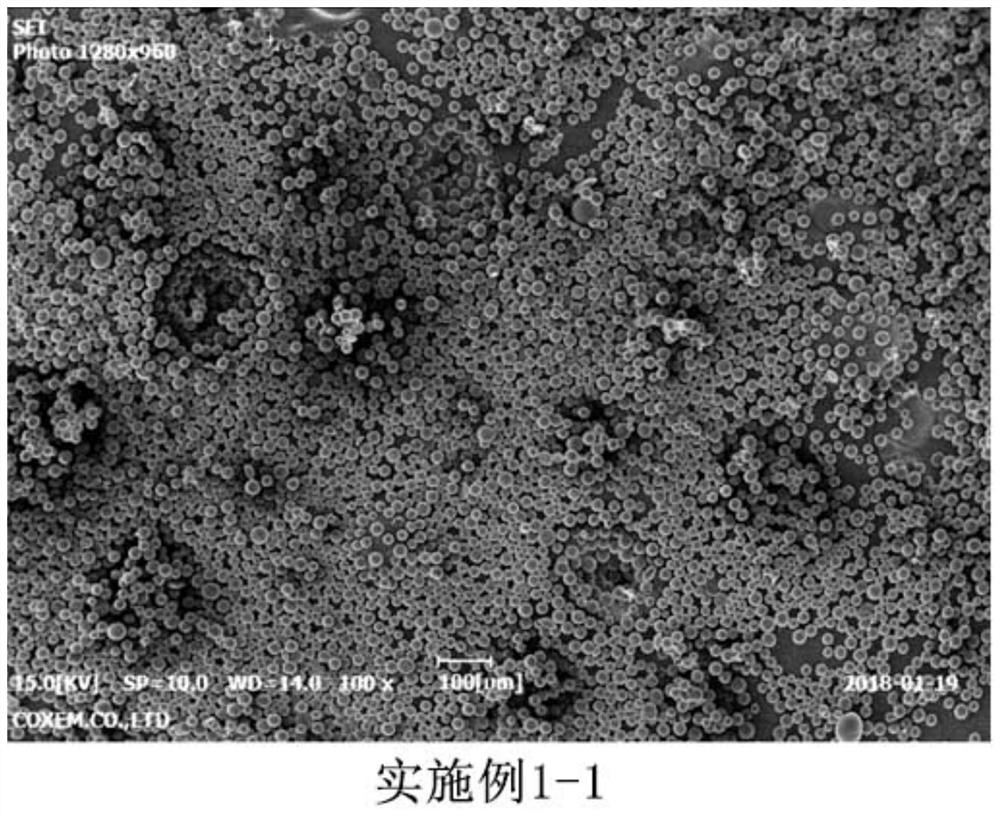

Embodiment 1-1

[0055] Example 1-1: Preparation of microspheres encapsulated with collagen peptides

[0056] By completely dissolving 9.98 g of biocompatible polymer Purasorb PC 04 (manufacturer: Corbion, Netherlands) and 0.02 g of palmitoyl-KTTKS (manufacturer: Incospharm, Korea) in 39.92 g of dichloromethane (manufacturer: JT Baker , USA) and 2.52 mL of methanol (manufacturer: Sigma Aldrich, USA), and then mix the two solutions to prepare a dispersed phase. A 2 w / v% polyvinyl alcohol aqueous solution (viscosity: 4.8 to 5.8 mPa·s) was used as the continuous phase, and 4000 mL of the continuous phase was supplied to an emulsification device equipped with a 10 μm diameter porous membrane while injecting the prepared dispersion phase to prepare microspheres. The prepared microsphere suspension was placed in a preparation container and stirred at a speed of 150 rpm. The temperature of the membrane emulsification device and the preparation vessel was maintained at 25°C.

[0057] When the inj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com