Acidic carbon quantum dot, preparation method and application thereof

A carbon quantum dot and acidic technology, which is applied in the field of acidic carbon quantum dots and its preparation, can solve the problems of environmental pollution and low conversion rate, and achieve the effects of no three wastes, improved particle size, and environmentally friendly raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

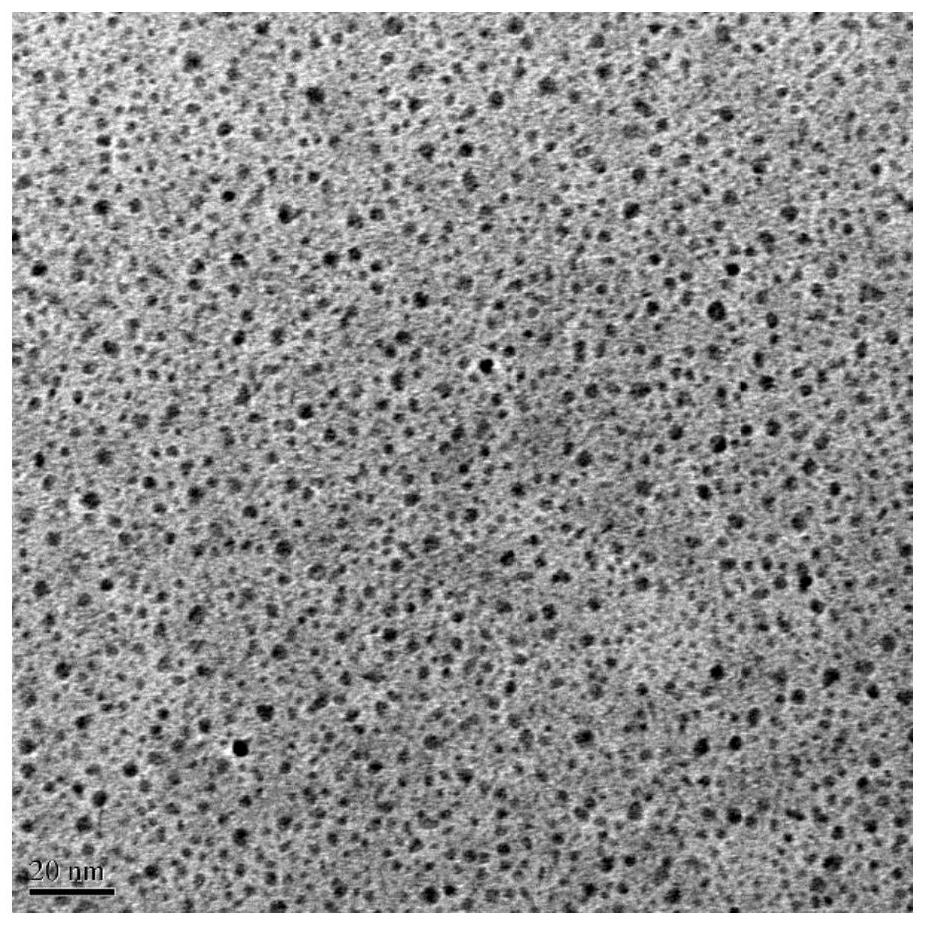

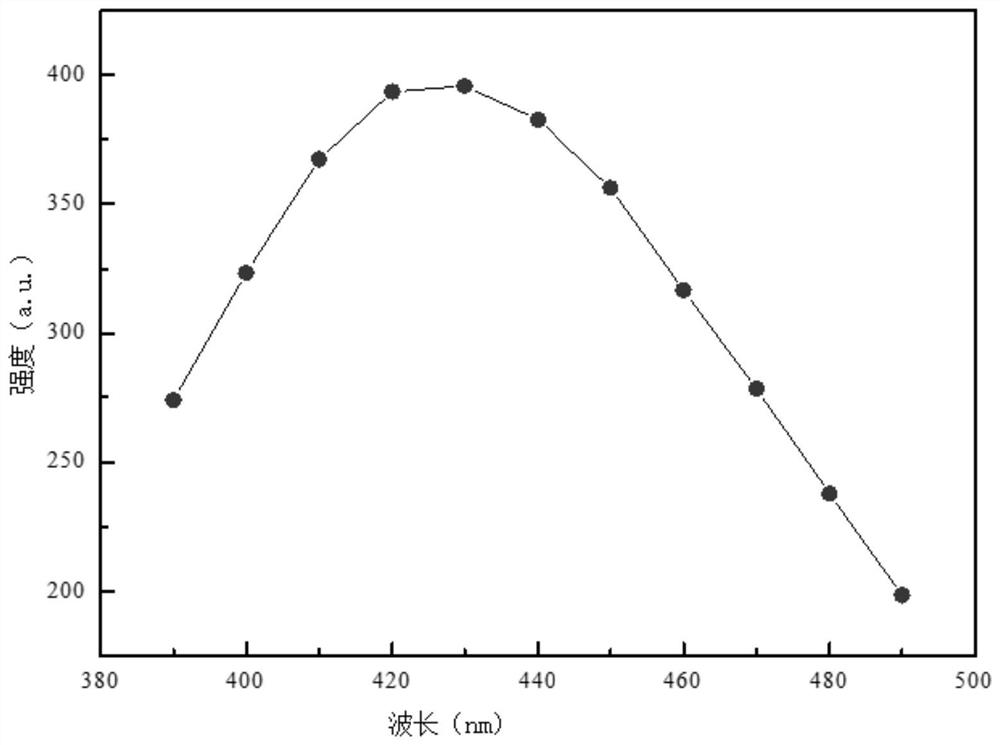

[0030] A preparation method of acidic carbon quantum dots, comprising the steps of:

[0031] S1: Mix L-phenylalanine and methanesulfonic acid (6.46g in total) with a substance ratio of 1:3 into a 100mL three-necked flask and raise the temperature to 110°C. After 2 hours of reaction, a uniform transparent solution is obtained. That is, the deep eutectic solvent A;

[0032] S2: Add 1g of deep eutectic solvent A and 30mL of distilled water into the hydrothermal kettle, put the hydrothermal kettle into an oven, and react at 210°C for 14h. Freeze-drying for 30 h to obtain acidic carbon quantum dots A.

[0033] Using the above-mentioned acidic carbon quantum dots A to catalyze the hydrolysis of cellulose to prepare furfural, the specific method includes the following steps:

[0034] Mix 1 g of absorbent cotton (100% cellulose content), 0.10 g of acidic carbon quantum dots A and 3 g of distilled water, and conduct a photocatalytic reaction at 110° C. for 6 h under natural light. A...

Embodiment 2

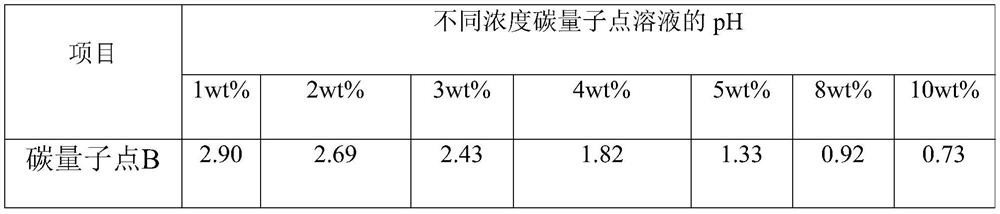

[0036] A preparation method of acidic carbon quantum dots, comprising the steps of:

[0037] S1: Mix p-aminophenylacetic acid and p-toluenesulfonic acid (total 8.39g) with a substance ratio of 1:2 into a 100mL three-necked flask and heat up to 120°C. After 1.5h of reaction, a uniform transparent solution is obtained. That is, the deep eutectic solvent B;

[0038] S2: Add 1g of deep eutectic solvent B and 35mL of distilled water into the hydrothermal kettle, put the hydrothermal kettle into an oven, and react at 200°C for 10h. Freeze-drying for 48 hours to obtain acidic carbon quantum dots B.

[0039] Using the above-mentioned acidic carbon quantum dots B to catalyze the hydrolysis of cellulose to prepare furfural, the specific method includes the following steps:

[0040] 1 g of corn stalks (88% cellulose content), 0.04 g of acidic carbon quantum dots B and 3 g of distilled water were mixed, and a photocatalytic reaction was carried out at 100° C. for 4 h under visible light...

Embodiment 3

[0042] A preparation method of acidic carbon quantum dots, comprising the steps of:

[0043] S1: Mix D-p-hydroxyphenylglycine and formic acid (total 8.54g) with a substance ratio of 1:0.5 and add it into a 100mL three-necked flask and raise the temperature to 60°C. After 2 hours of reaction, a uniform transparent solution is obtained, that is, low Eutectic solvent C;

[0044] S2: Add 1 g of deep eutectic solvent C and 25 mL of distilled water into the hydrothermal kettle, put the hydrothermal kettle in an oven, and react at 220°C for 8 hours. Freeze-drying for 24 hours to obtain acidic carbon quantum dots C.

[0045] Using the above-mentioned acidic carbon quantum dots C to catalyze the hydrolysis of cellulose to prepare furfural, the specific method includes the following steps:

[0046]Mix 1 g of rice husk (42% cellulose content), 0.01 g of acidic carbon quantum dots C and 3 g of distilled water, and conduct a photocatalytic reaction at 80° C. for 1.5 h under visible light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com