Quick-setting cement-based capillary crystalline waterproof material and preparation method thereof

A technology of permeable crystallization and quick-setting cement, applied in the field of quick-setting cement-based permeable crystalline waterproof material and its preparation, can solve the problems of damaged concrete structure, slow hydration speed, long water storage time, etc., and achieve high early strength , to ensure the effect of compactness and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

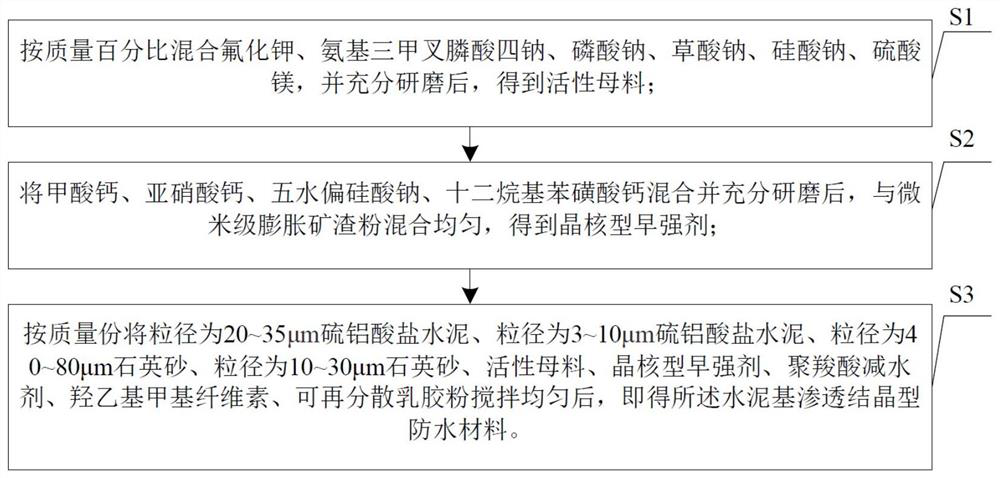

[0023] The preparation method of quick-setting cement-based permeable crystalline waterproof material comprises the following steps:

[0024] S1: Weigh 10% of potassium fluoride, 10% of tetrasodium aminotrimethylene phosphonate, 20% of sodium phosphate, 10% of sodium oxalate, 10% of magnesium sulfate, and make up the balance with sodium silicate, mix well and grind thoroughly After that, the active masterbatch is obtained;

[0025] S2: After mixing and fully grinding calcium formate, calcium nitrite, sodium metasilicate pentahydrate, and calcium dodecylbenzenesulfonate, they are evenly mixed with micron-sized expanded slag powder with a particle size of 1-3 μm to obtain crystal nuclei Type early strength agent; described crystal nucleus type early strength agent is 1:0.5 by the mass ratio of calcium formate, calcium nitrite, sodium metasilicate pentahydrate, calcium dodecylbenzenesulfonate, micron-scale expansion slag powder: 0.6:0.3:1.2;

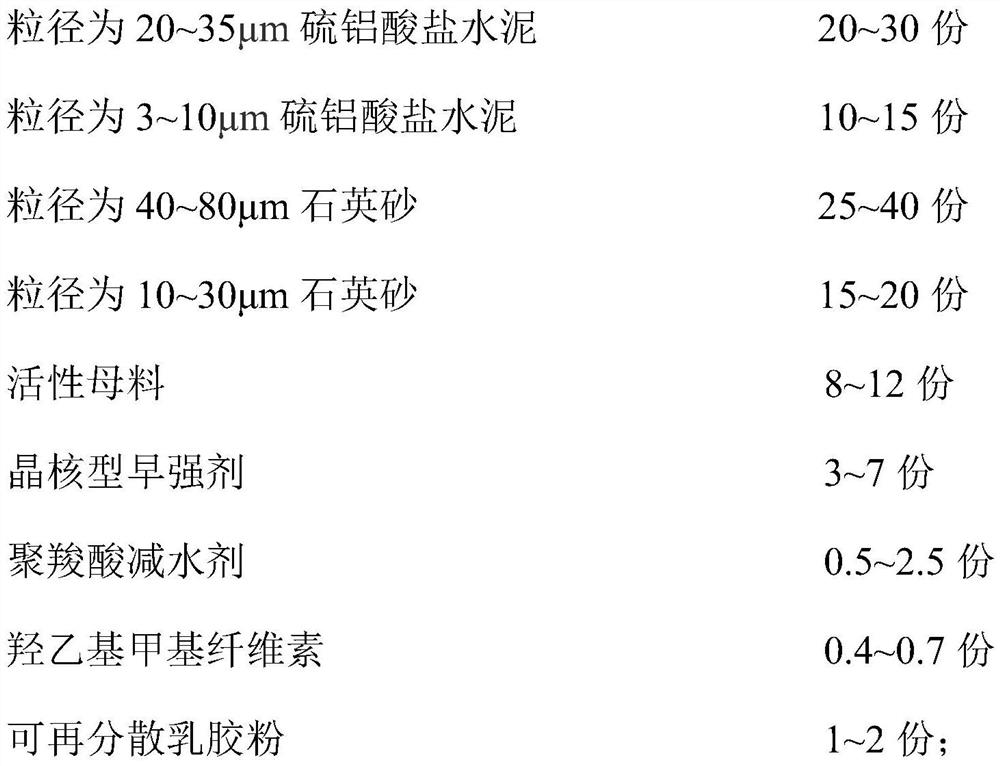

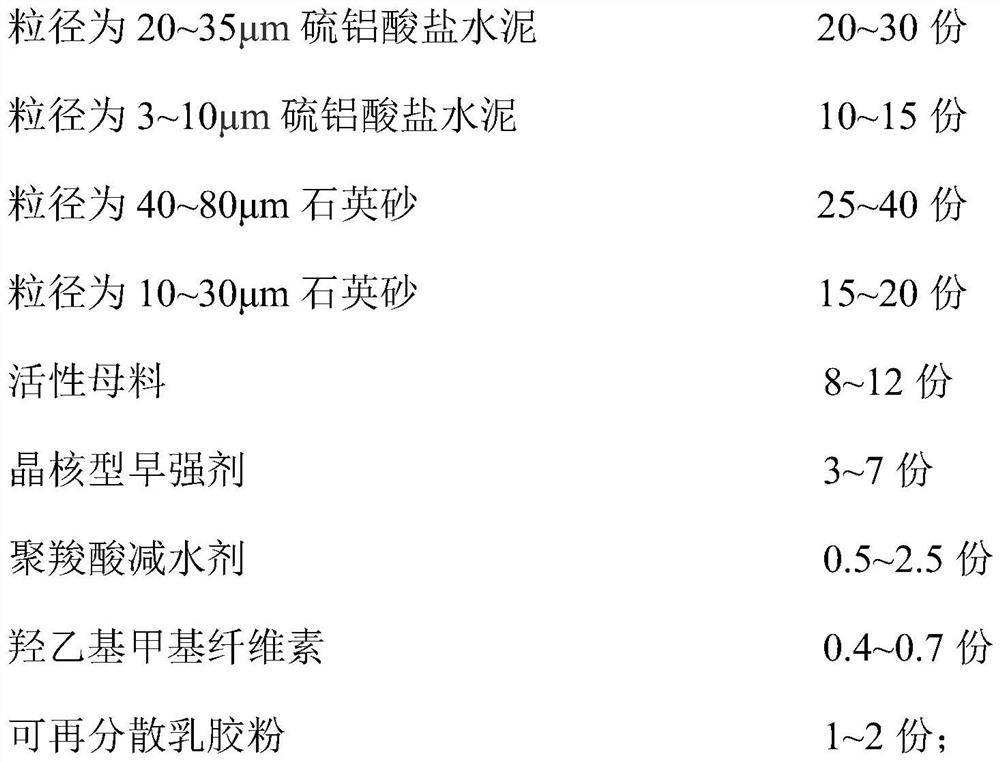

[0026] S3: In parts by mass, 20 pa...

Embodiment 2

[0028] The preparation method of quick-setting cement-based permeable crystalline waterproof material comprises the following steps:

[0029] S1: Weigh 12% of potassium fluoride, 12% of tetrasodium aminotrimethylene phosphonate, 21% of sodium phosphate, 12% of sodium oxalate, 12% of magnesium sulfate according to mass percentage, make up the balance with sodium silicate, mix well and grind thoroughly After that, the active masterbatch is obtained;

[0030] S2: After mixing and fully grinding calcium formate, calcium nitrite, sodium metasilicate pentahydrate, and calcium dodecylbenzenesulfonate, they are evenly mixed with micron-sized expanded slag powder with a particle size of 1-3 μm to obtain crystal nuclei Type early strength agent; the mass ratio of described crystal nucleus type early strength agent by calcium formate, calcium nitrite, sodium metasilicate pentahydrate, calcium dodecylbenzenesulfonate, micron-scale expansion slag powder is 1:0.6: 0.9:0.4:1.6;

[0031] S3...

Embodiment 3

[0033] The preparation method of quick-setting cement-based permeable crystalline waterproof material comprises the following steps:

[0034] S1: Weigh 14% of potassium fluoride, 14% of tetrasodium aminotrimethylene phosphonate, 23% of sodium phosphate, 14% of sodium oxalate, 14% of magnesium sulfate according to mass percentage, make up the balance with sodium silicate, mix well and grind thoroughly After that, the active masterbatch is obtained;

[0035] S2: After mixing and fully grinding calcium formate, calcium nitrite, sodium metasilicate pentahydrate, and calcium dodecylbenzenesulfonate, they are evenly mixed with micron-sized expanded slag powder with a particle size of 1-3 μm to obtain crystal nuclei Type early strength agent; described crystal nucleus type early strength agent is 1:0.7 by the mass ratio of calcium formate, calcium nitrite, sodium metasilicate pentahydrate, calcium dodecylbenzenesulfonate, micron-scale expansion slag powder: 1.2:0.5:2;

[0036] S3: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com