Preparation process and application of highland barley beta-glucan extract

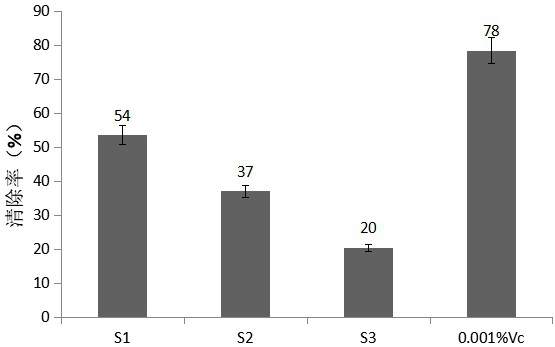

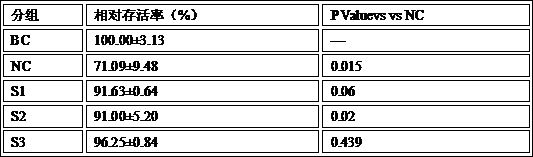

A technology of glucan and extract, which is applied in the field of extraction and preparation of highland barley β-glucan, which can solve the problems that the stability cannot meet the application requirements, unfavorable solid-liquid separation, difficult equipment operation, etc., and achieve good free radical scavenging And anti-radiation effect, good safety and stability, good free radical scavenging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

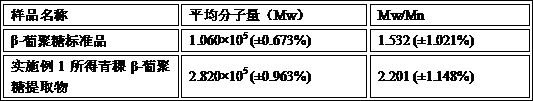

[0059] Example 1 Preparation of barley β-glucan extract

[0060] (1) Raw material pretreatment: dry the highland barley at 50°C, crush, pass through a 0.5mm sieve, and set aside;

[0061] (2) Enzymatic extraction: the pretreated raw materials were extracted by water, the ratio of solid to liquid m / m was 1:15, the pH was adjusted to 7.5, 0.05wt% lipase was added into the water, reacted at 50°C for 1 h, and the pH was adjusted to 5.5 , add 0.05wt% pectinase into the water, and react at 50°C for 1h;

[0062] (3) Coarse filtration: use a frame filter equipped with a filter paper plate with a pore size of 15 μm to achieve solid-liquid separation and collect the coarse filtrate;

[0063] (4) Removal of starch and decolorization: Add 0.02% by weight α-high temperature resistant amylase to the crude filtrate, react at 85°C for 10 minutes, then add activated carbon with a weight percentage of 2% of the crude filtrate, heat up to 95°C for 1 hour, use Plate and frame filtration equippe...

Embodiment 2

[0067] Example 2 Preparation of barley β-glucan extract

[0068] (1) Raw material pretreatment: dry the highland barley at 70°C, crush, pass through a 1.5 mm sieve, and set aside;

[0069] (2) Enzymatic extraction: the pretreated raw materials were extracted with water, the ratio of solid to liquid m / m was 1:30, the pH was adjusted to 7, 0.01wt% lipase was added into the solvent, reacted at 60°C for 3 h, and the pH was adjusted 5.0, add 0.10wt% pectinase in the amount of solvent, and react at 55°C for 3h;

[0070] (3) Coarse filtration: use a frame filter equipped with a filter paper plate with a pore size of 25 μm to achieve solid-liquid separation and collect the crude filtrate;

[0071] (4) Removal of starch and decolorization: Add 0.05% by weight of α-high temperature resistant amylase to the crude filtrate, react at 90°C for 5 minutes, then add activated carbon with a mass percentage of 3% of the crude filtrate, heat up to 100°C for 1 hour, use Plate and frame filtratio...

Embodiment 3

[0075] Example 3 Preparation of Highland Barley-β-glucan Extract

[0076] (1) Raw material pretreatment: dry the highland barley at 60°C, crush, pass through a 1.0 mm sieve, and set aside;

[0077] (2) Enzymatic extraction: the pretreated raw materials are extracted with water, the ratio of solid to liquid m / m is 1:10, the pH is adjusted to 8, 0.10wt% lipase is added into the solvent, reacted at 40°C for 5 hours, and the pH is adjusted to 6.0 , adding 0.01wt% pectinase into the solvent, reacting at 60°C for 5h;

[0078] (3) Coarse filtration: use a frame filter equipped with a 20 μm pore size filter paper plate to achieve solid-liquid separation and collect the crude filtrate;

[0079] (4) Removal of starch and decolorization: add 0.03% by weight α-high temperature resistant amylase to the crude filtrate, react at 80°C for 15 minutes, then add 1% activated carbon to the crude filtrate, heat up to 80°C for 0.5h, Filter with a plate frame equipped with a 0.5 μm pore size filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com