Segmented enzymolysis process of plukenetia volubilis linneo, and plukenetia volubilis linneo peptide prepared by same

The technology of meridian fruit and enzymolysis, applied in the field of meridian fruit peptide, can solve the problems of difficult to control fermentation process, complicated preparation process, complicated operation, etc., and achieve the effect of improving peptide yield, uniform molecular weight and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A segmented enzymatic hydrolysis process of saiteng fruit, comprising the steps of:

[0033] S1. Raw material pretreatment: pulverize the cane fruit cake, and then pass through a 100-mesh sieve to obtain the cane fruit meal powder for later use;

[0034] S2. High-temperature treatment: add sachaeji fruit meal powder into pure water according to the material-to-liquid ratio of 1:20 (w / v), heat it in a water bath at 95°C, and keep it warm for 6 hours;

[0035] S3. Proteolysis: After high-temperature denaturation of cane fruit protein, take it out and cool it to about 50°C, add 0.75% alkaline protease, enzymolyze it at pH 10 and 60°C for 6 hours, centrifuge after the enzymolysis is completed, and collect the solution A;

[0036] S4. Secondary enzymatic hydrolysis: Add pure water to the sediment according to the ratio of material to liquid 1:10 (w / v), add 0.25% neutral protease, and enzymolyze at pH 7 and 50°C for 3 hours. After the enzymolysis is completed Perform centri...

Embodiment 2

[0040] A segmented enzymatic hydrolysis process of saiteng fruit, comprising the steps of:

[0041] S1. Raw material pretreatment: pulverize the cane fruit cake, and then pass through a 100-mesh sieve to obtain the cane fruit meal powder for later use;

[0042] S2. High-temperature treatment: add sachaeji fruit meal powder into pure water according to the material-to-liquid ratio of 1:30 (w / v), heat in a water bath at 100°C, and keep warm for 4 hours;

[0043] S3. Proteolysis: After high-temperature denaturation of the cane fruit protein, take it out and cool it to about 50°C, add 0.9% alkaline protease, and enzymolyze it at pH 9 and 50°C for 3 hours, centrifuge after the enzymolysis is completed, and collect the solution A;

[0044] S4. Secondary enzymatic hydrolysis: add pure water to the sediment according to the ratio of material to liquid 1:15 (w / v), add 0.4% neutral protease, and enzymolyze at pH 7 and 50°C for 3 hours, after the enzymolysis is completed Perform centri...

experiment example 1

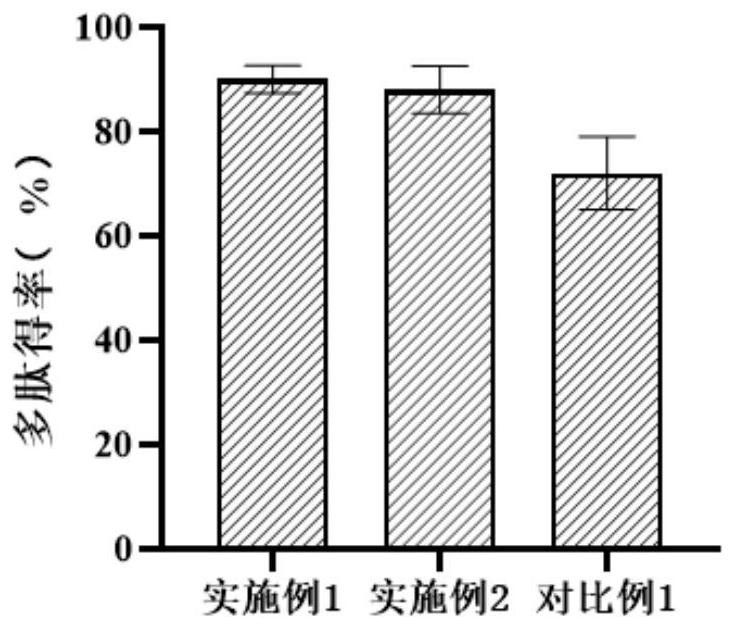

[0055] Determination of the yield of the polypeptide of the United Teng fruit:

[0056] Take 5 mL of enzymatic hydrolysis supernatant to measure its protein content; take another 5 mL of enzymatic hydrolysis supernatant, add 5 mL of 20% trichloroacetic acid solution, shake well, let stand for 30 min, centrifuge at 4000 r / min for 20 min, and take supernatant to determine peptide yield.

[0057] Take respectively implementation case 1, implementation case 2, and the prepared satocarpine samples of comparison case 1, and measure its protein content; after taking another batch of samples to make a solution, add 5mL20% trichloroacetic acid solution, shake well, Let it stand for 30 minutes, centrifuge at 4000r / min for 20 minutes, take the supernatant to measure the yield of polypeptide, the calculation formula is:

[0058] Peptide yield = (acid-soluble protein content after hydrolysis - acid-soluble protein content before hydrolysis) / total protein content × 100%

[0059] The resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com