Anti-microbial mould-proof floor coating with glaze texture

A ground coating, antibacterial and antifungal technology, applied in the field of coatings, can solve the problems of low smoothness, ornamental, reduced aesthetics, poor gloss, etc., achieve high mechanical strength, improved antibacterial and antifungal effects, and reduced firing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

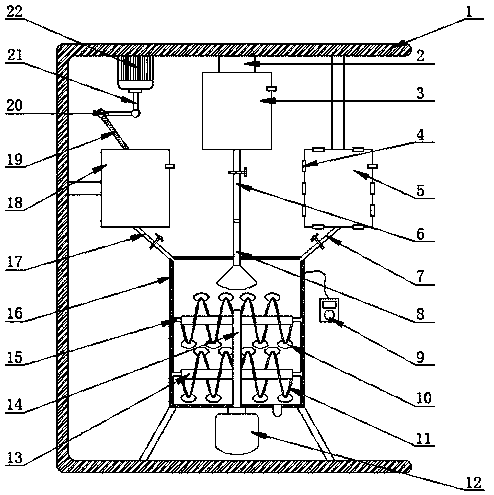

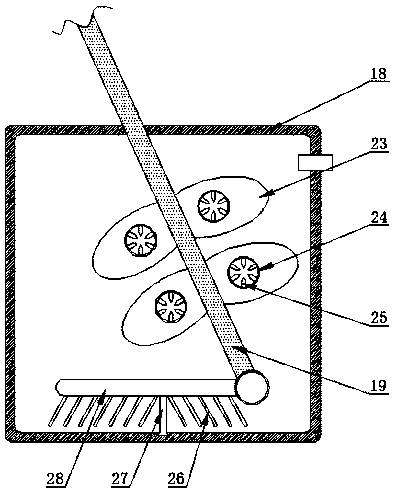

Method used

Image

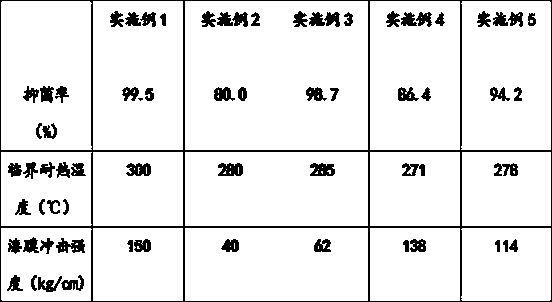

Examples

Embodiment 1

[0036] An antibacterial and mildew-proof ground coating with a glaze texture, the ground coating is composed of a primer A and a surface coating B, and the primer A is composed of 45% nepheline, 20% kaolin, and 15% nano-oxidized Aluminum powder, 8% quartz, 7% firing additive and 5% nano-silver powder;

[0037] And the firing additive is formed by mixing silicon dioxide powder, barium oxide powder, strontium oxide powder and magnesium oxide powder in a weight percentage of 2:1:1:1;

[0038] Primer coating A is prepared by the following method: First, nepheline and quartz are weighed and ball-milled, mixed with nano-alumina powder and firing additives, and then introduced into a muffle furnace for gradient firing and passed into Helium is used as a protective gas, and the temperature and time of the first gradient firing are controlled at 1000 degrees and 3.5 hours respectively, the temperature and time of the second gradient firing are controlled at 1300 degrees and 1.5 hours r...

Embodiment 2

[0044] An antibacterial and antifungal floor coating with a glaze texture, the difference from Example 1 is that there are only the raw material composition of the surface coating B and its preparation method.

Embodiment 3

[0046] A kind of antibacterial mildew-proof floor paint with glaze texture, the difference with embodiment 1 is that primer A is made of 49% nepheline, 22% kaolin, 16% nano-alumina powder respectively by weight percentage , 8% quartz and 5% nano-silver powder;

[0047]Primer coating A is prepared by the following method: First, nepheline and quartz are weighed and ball-milled, mixed with nano-alumina powder, and then introduced into a muffle furnace for 1200 degrees, 20MPa and 5 hours of constant temperature firing system and pass into helium as a protective gas, and after decompression, cooling and filtration, to obtain the mixture A, then kaolin and water are mixed in a ratio of 2:3 by weight percentage, and then mixed with the mixture A, The nano-silver powder is wet-milled and dehydrated together to obtain primer A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com