Lithium-sulfur battery cathode material and preparation method thereof

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of low utilization of active materials, affecting the normal operation of electrodes, volume expansion, etc., to improve cycle stability and rate performance , Promote redox kinetics and relieve volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

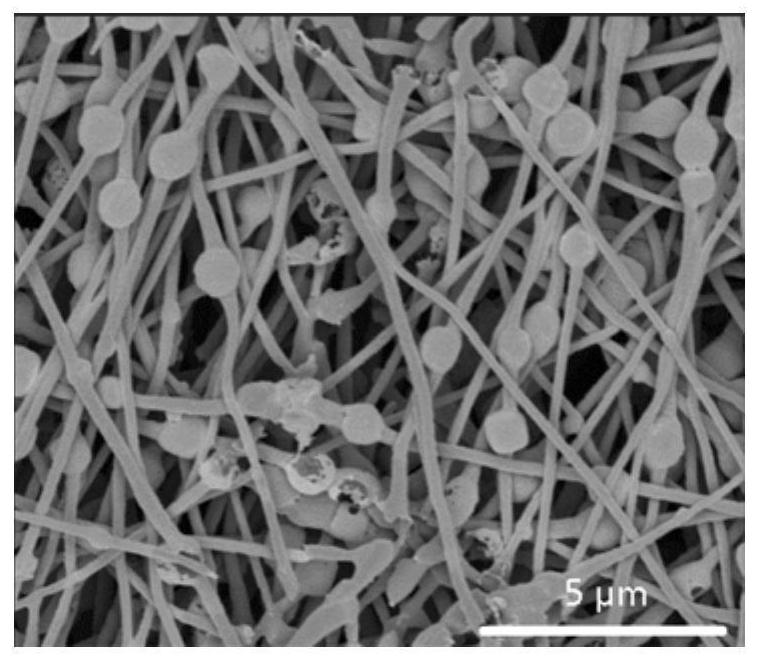

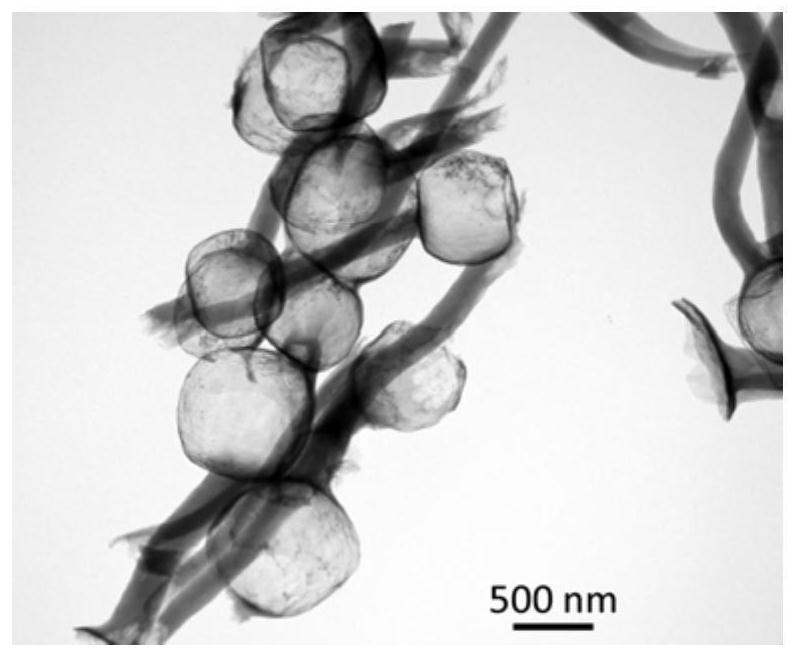

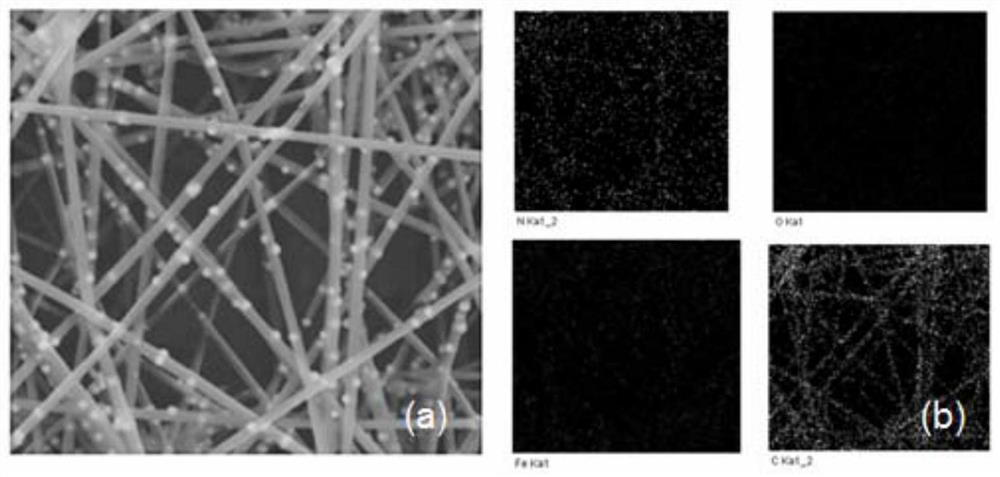

[0037] Under mechanical stirring, slowly add 90mL 6.0mol / L NaOH solution into 100mL 2.0mol / L FeCl 3 solution, stirring was continued for 10 minutes. Subsequently, the reaction vessel was sealed and aged in an oven at 100° C. for 8 days at a constant temperature. After taking out and cooling to room temperature, the supernatant was discarded, and the red muddy solid in the lower layer was washed with deionized water three times and then dried at 60°C for 12 hours to obtain red α-Fe 2 o 3 powder. The PAN and PVP with an average molecular weight of 150,000 are dissolved in DMF at a mass ratio of 3:1 to prepare 100ml, 0.2g / ml of PAN / PVP mixed spinning solution, and the prepared α-Fe 2 o 3 The particles are dissolved in the mixed spinning solution to form a suspension, and the α-Fe in the PAN / PVP mixed spinning solution 2 o 3 The amount of particles added is 10g. After electrospinning at 25°C and relative humidity below 40%, it is sealed and stored to obtain N-doped PAN-coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com