Preparation method of sterilization disinfectant for killing coronaviruses

A technology of coronavirus and disinfectant, which is applied in the preparation of bactericidal disinfectant and compound bactericide, can solve problems such as poor compatibility, achieve stable performance, maintain compatibility and stability, and have good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

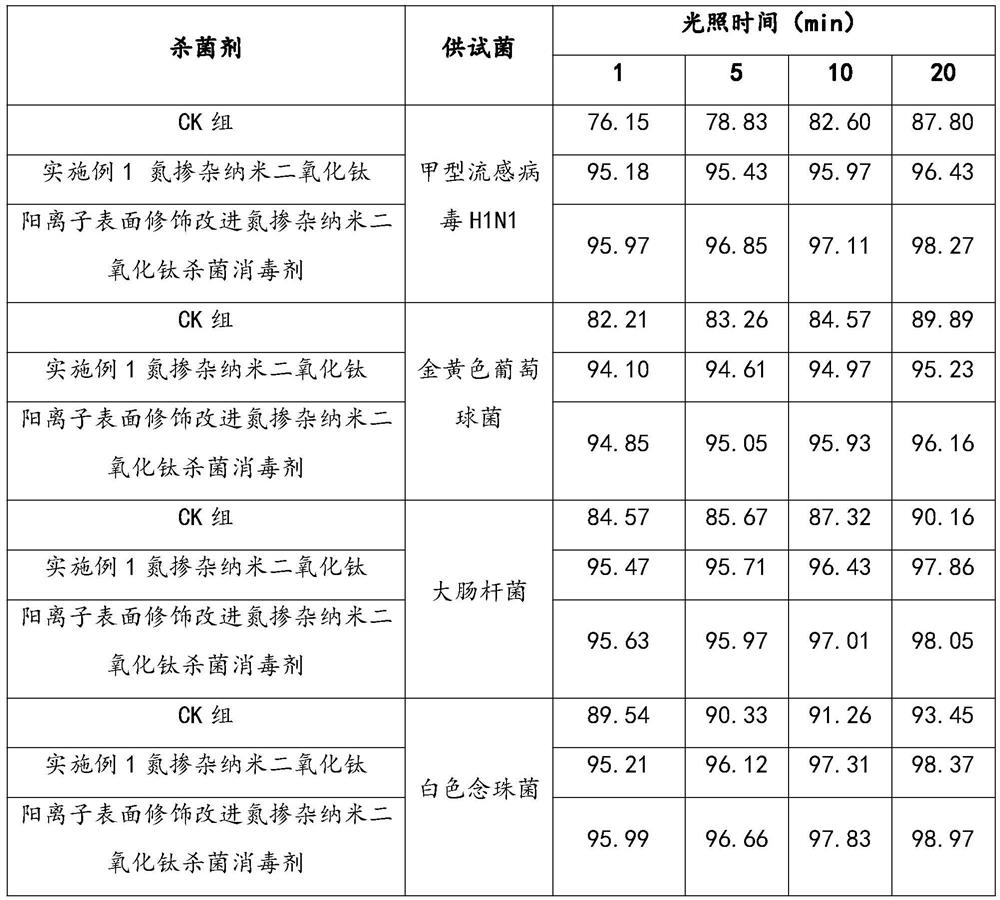

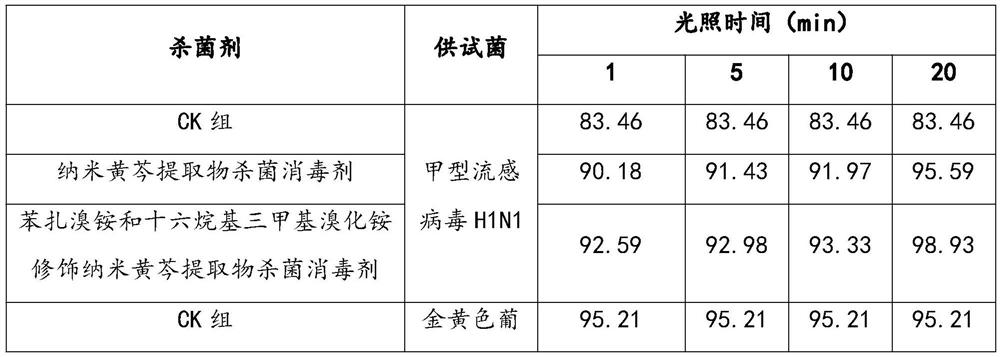

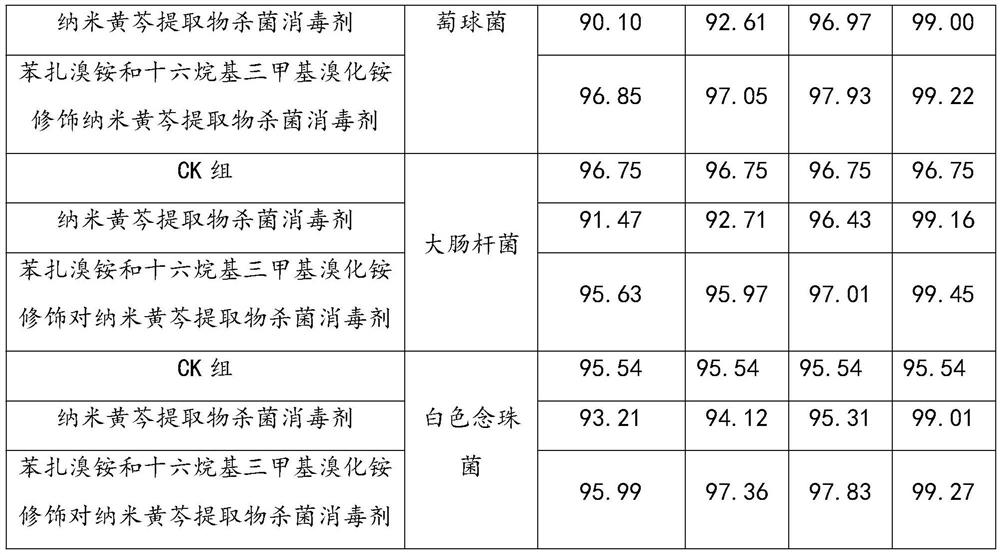

Examples

Embodiment 1

[0052] 1. Preparation of nitrogen-doped nano-titanium dioxide bactericidal disinfectant

[0053] The amount of substance ratio m (n-tetrabutyl titanate): m (absolute ethanol): n (deionized water): n (acetic acid): n (guanidine acetate) = 1: 20: 1: 0.1: 0.10; at room temperature Under certain conditions, the mixed solution was obtained according to the volume ratio (V butyl titanate: V absolute ethanol = 1:4), and the magnetic stirrer was stirred at 400r / min, and the acetic acid solution and deionized water were slowly added dropwise into the mixed system. The pH value of the solution is 2.0; then slowly drop the guanidine acetate solution into the butyl titanate solvent solution according to the volume ratio (V guanidine acetate: V butyl titanate = 1:2), and stir thoroughly for 1 hour to obtain a dispersion; the above dispersion Put it into a drying device, dry it at 80°C for 10 hours, and then grind it to obtain a powder. Finally, the powder is placed in a muffle furnace and...

Embodiment 2

[0076] 1. Preparation of nitrogen-doped nano-titanium dioxide bactericidal disinfectant

[0077] The amount of substance ratio m (n-tetrabutyl titanate): m (absolute ethanol): n (deionized water): n (organic acid): n (nitrogen source) = 1: 20: 1: 0.1: 0.03, in Under the condition of room temperature, the mixed solution was obtained according to the volume ratio (V butyl titanate: V absolute ethanol = 1: 4), and the magnetic stirrer was stirred at 400r / min, and the phytic acid solution and deionized water were slowly added dropwise, and mixed The pH value of the system solution is 2.0; then slowly drop the amino acid solution into the butyl titanate solvent solution and deionized water according to the volume ratio (V amino acid: V butyl titanate = 1:2), and stir thoroughly for 1 hour to obtain a dispersion; Put the above dispersion into a drying device, dry at 80° C. for 10 h, and then grind to obtain a powder. Finally, the powder is placed in a muffle furnace and heated at 4...

Embodiment 3

[0099] 1. Improve the preparation of nitrogen-doped nano-titanium dioxide bactericidal disinfectant

[0100] The amount of substance ratio m (n-tetrabutyl titanate): m (absolute ethanol): n (water): n (tannic acid): n (aqueous chitin) = 1: 20: 1: 0.1: 0.05, in Under the condition of room temperature, the mixed solution was obtained according to the volume ratio (V butyl titanate: V absolute ethanol = 1: 4), and the magnetic stirrer was stirred at 400r / min, and the tannic acid solution and deionized water were slowly added dropwise, The pH value of the mixed system solution is 2.0; then slowly drop the aqueous chitin solution into the butyl titanate solvent solution according to the volume ratio (V water-based chitin: V butyl titanate = 1:2), and stir thoroughly for 1 hour to obtain a dispersion ; Put the above dispersion into a drying device, dry it at 80°C for 10 hours, and grind it to obtain a powder. Finally, the powder is placed in a muffle furnace and heated at 450°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com