Preparation method of palladium catalyst, catalyst and application

A palladium catalyst and a catalyst technology are applied in the field of preparation of palladium catalysts, which can solve the problems of difficult industrial-scale application production, increase the use of precious metals, and low utilization rate of palladium, and achieve good reproducibility, low price, and industrial application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

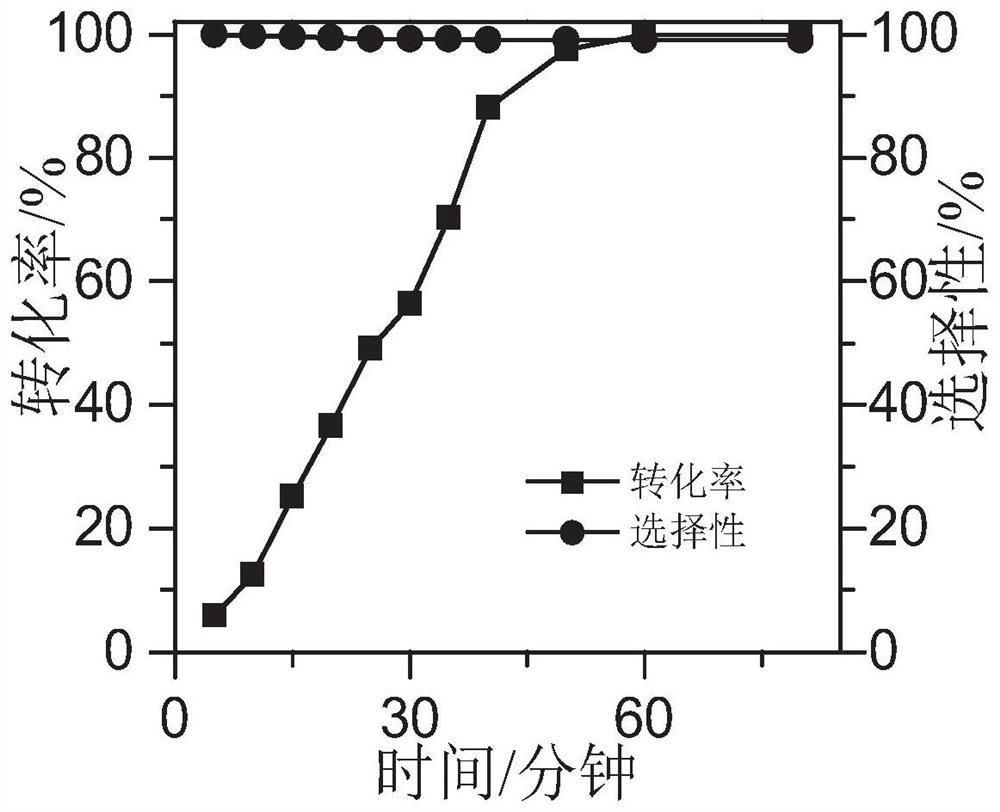

[0045] Embodiment 1: palladium nanosheet preparation catalyst carries out semi-hydrogenation reaction

[0046] S1: choose two-dimensional palladium nanosheets (Pd Ns) dispersed in ethanol solvent, add triphenylphosphine sulfur (PPh 3 S) As modifier H, the molar ratio of modifier H:Pd is 1:0.4, the stirring time is 1 h, the stirring temperature is 20°C, the catalyst is filtered out with suction, washed and dried with ultrapure water for 12 h to prepare PPh 3 S-Pd Ns catalyst.

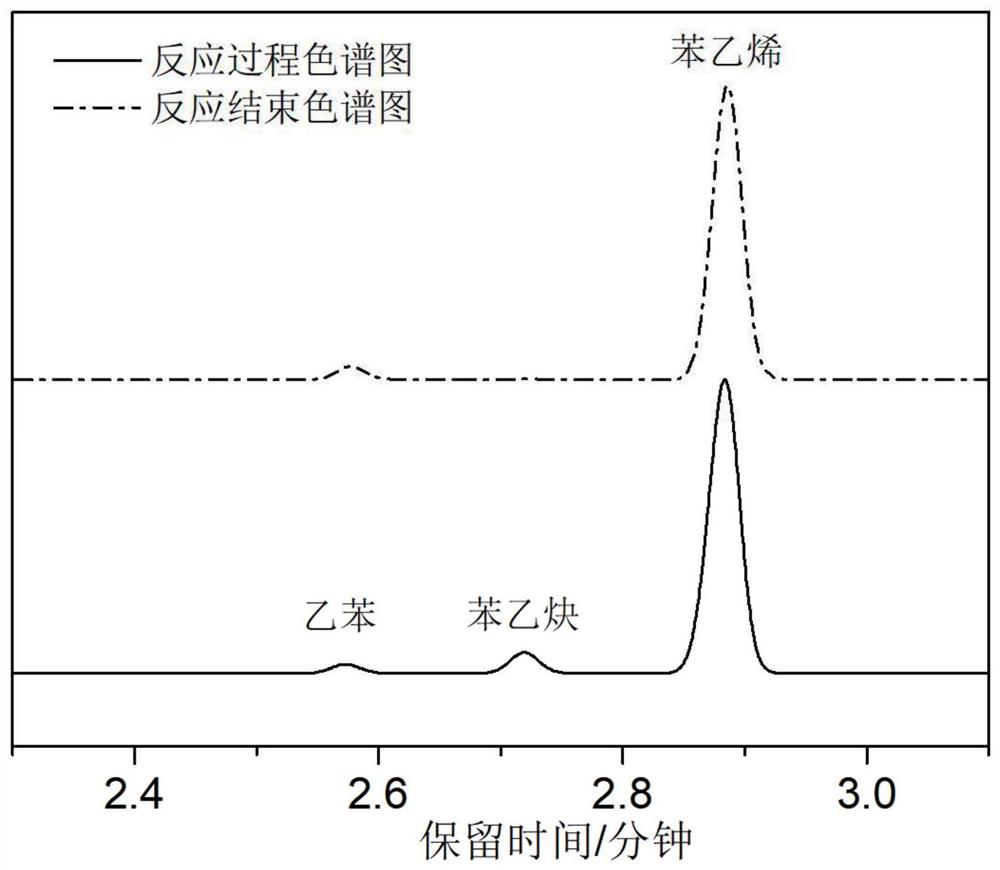

[0047] S2: The prepared PPh 3The S-Pd Ns catalyst uses phenylacetylene as a substrate for semi-hydrogenation reaction. Reaction steps: transfer 20ml of ethanol solvent to a 48ml reaction flask, select 2mmol of phenylacetylene into the reaction flask and ultrasonically disperse for 1min, set the temperature to 30°C, add a corresponding amount of catalyst, the molar ratio of substrate to Pd is 2000:1, replace hydrogen 3 times and keep 1 bar of hydrogen in the reaction bottle, set the rotation speed to 10...

Embodiment 2

[0049] S1: Disperse Pd / C with a Pd mass fraction of 5% in ethanol solvent, add triphenylphosphine sulfur (PPh 3 S) As modifier H, the molar ratio of modifier H:Pd is 1:0.25, the stirring time is 1 h, the stirring temperature is 30°C, the catalyst is filtered out with suction, washed and dried with ultrapure water for 12 h to prepare PPh 3 The S-Pd / C catalyst is ready for use.

[0050] S2: The prepared PPh 3 The S-Pd / C catalyst uses phenylacetylene as a substrate for semi-hydrogenation reaction. Reaction steps: transfer 20ml of ethanol to a 48ml reaction flask, select 2mmol of phenylacetylene into the reaction flask and ultrasonically disperse it for 1min, set the temperature to At 30°C, add a corresponding amount of catalyst, the molar ratio of substrate to Pd is 2000:1, replace hydrogen 3 times and keep 1bar of hydrogen in the reaction bottle, set the rotation speed to 1000rpm and turn on the stirring. Timely sampling is carried out the detection of product by gas chromatog...

Embodiment 3

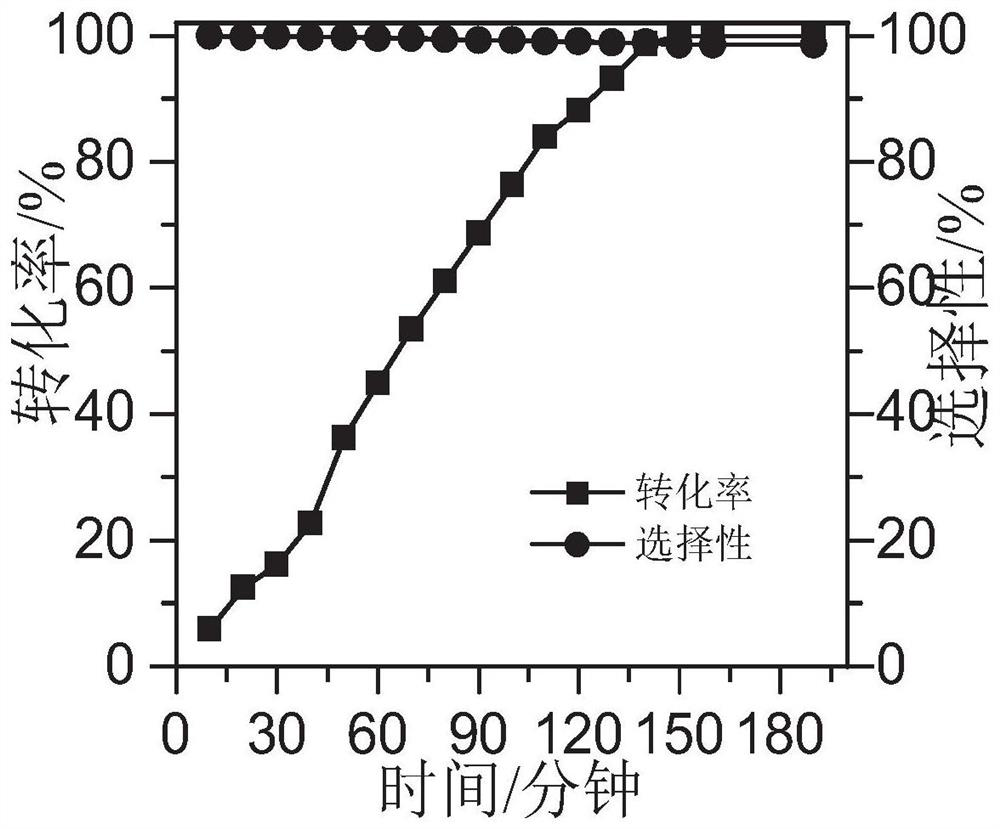

[0051] Embodiment 3: test the stability of catalyst of the present invention

[0052] S1: Select Pd / C with a Pd mass fraction of 5% and disperse it in an ethanol solvent, add triphenylphosphine sulfur (PPh 3 S) As modifier H, the molar ratio of modifier H:Pd is 1:0.4, the stirring time is 1h, the stirring temperature is 25°C, the catalyst is filtered out with suction, washed and dried with ultrapure water for 12h to prepare PPh 3 S-Pd / C catalyst.

[0053] S2: The prepared PPh 3 The S-Pd / C catalyst uses phenylacetylene as a substrate for semi-hydrogenation reaction. Reaction steps: transfer 20ml of ethanol to a 48ml reaction flask, select 2mmol of phenylacetylene into the reaction flask and ultrasonically disperse it for 1min, set the temperature to 30°C, add a corresponding amount of catalyst, the molar ratio of substrate to Pd is 2000:1, replace hydrogen 3 times and keep 1 bar of hydrogen in the reaction bottle, set the rotation speed to 1000rpm and turn on the stirring. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com