Carbon nano-based anti-electromagnetic radiation fabric and preparation method thereof

An anti-electromagnetic radiation, carbon nanotechnology, applied in the field of fabric processing, can solve problems such as health hazards, electromagnetic wave radiation pollution, and unsatisfactory electromagnetic shielding performance, and achieve the effect of excellent specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

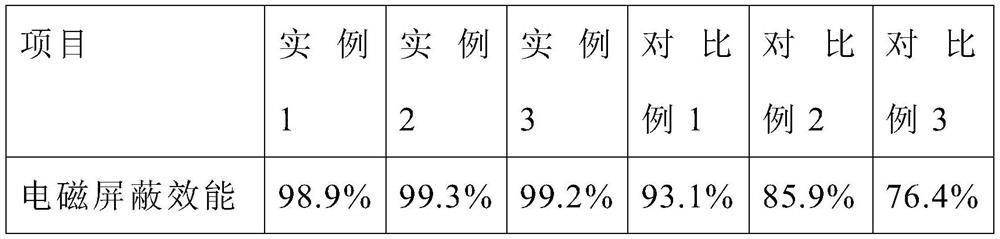

Examples

example 1

[0053] S1: Prepare materials;

[0054] S2: Preparation of carbonized fibers:

[0055] Take polystyrene particles, dissolve them in tris buffer solution, and disperse them ultrasonically for 10 minutes to obtain material A; take polyacrylonitrile, iron acetylacetonate and dimethylformamide, mix and stir for 10 hours, then add material A, and continue stirring 30min, then add dopamine, stir for 24h, and electrospin to obtain spun fibers;

[0056] Take the spun fiber, place it at 250°C for pre-oxidation for 5 hours, then place it under nitrogen atmosphere, heat it up to 300°C, keep it warm for 1 hour, then heat it up to 650°C, carbonize it for 3 hours, then heat it up to 690°C, keep it warm for 20-30 minutes, After cooling down, place in nitric acid solution, heat treatment at 60°C for 12 hours, wash and dry to obtain carbonized fiber; the heating rate is 5°C / min;

[0057] S3: Preparation of blended yarn:

[0058] Take carbonized fibers, carbon nanotube fibers and silicon carb...

example 2

[0065] S1: Prepare materials;

[0066] S2: Preparation of carbonized fibers:

[0067] Take polystyrene particles, dissolve them in tris buffer solution, and disperse them ultrasonically for 12 minutes to obtain material A; take polyacrylonitrile, iron acetylacetonate and dimethylformamide, mix and stir for 12 minutes, then add material A, and continue stirring 35min, then add dopamine, stir for 26h, and electrospin to obtain spun fibers;

[0068] Take the spun fiber, pre-oxidize it at 255°C for 5.5 hours, then put it under nitrogen atmosphere, heat up to 350°C, keep it for 1.1h, then raise it to 655°C, carbonize it for 3.2h, then raise it to 695°C, keep it for 25min , placed in nitric acid solution after cooling down, heated at 62°C for 12.5h, washed and dried to obtain carbonized fibers; the heating rate was 5°C / min;

[0069] S3: Preparation of blended yarn:

[0070] Take carbonized fibers, carbon nanotube fibers and silicon carbide fibers, parallel them and twist them to ...

example 3

[0077] S1: Prepare materials;

[0078] S2: Preparation of carbonized fibers:

[0079] Take polystyrene particles, dissolve them in tris buffer solution, and disperse them ultrasonically for 15 minutes to obtain material A; take polyacrylonitrile, iron acetylacetonate and dimethylformamide, mix and stir for 15 hours, then add material A, and continue stirring 40min, then add dopamine, stir for 28h, and electrospin to obtain spun fibers;

[0080] Take the spun fiber, pre-oxidize it at 260°C for 5-6 hours, then put it under nitrogen atmosphere, heat it up to 400°C, keep it warm for 1.2h, then raise it to 660°C, carbonize it for 3.5h, then raise it to 700°C, keep it warm 30min, after cooling down, place in nitric acid solution, heat treatment at 65°C for 13h, wash and dry to obtain carbonized fiber; the heating rate is 6°C / min;

[0081] S3: Preparation of blended yarn:

[0082] Take carbonized fibers, carbon nanotube fibers and silicon carbide fibers, parallel them and twist th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com