Preparation method of titanium tetraisopropoxide

A technology of titanium tetraisopropoxide and isopropanol, which is applied in the field of preparation of titanium tetraisopropoxide, can solve the problems that the purity is not easy to meet the requirements, is not suitable for large-scale production, and has complicated operation procedures, and is convenient for large-scale production and application. , The requirements of equipment are reduced, and the operation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

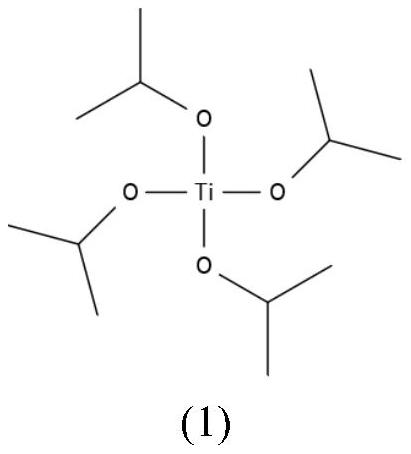

[0030] The embodiment of the present invention provides a kind of preparation method of titanium tetraisopropoxide, comprises the steps:

[0031] Mixing solvent, titanium tetrachloride and isopropanol to prepare a mixed reaction system;

[0032] Dialkylamine is added into the mixed reaction system for reaction, and the obtained reactant is processed to prepare the titanium tetraisopropoxide.

[0033] The reaction principle of the preparation method of above-mentioned titanium tetraisopropoxide can be expressed as follows by chemical equation (taking diethylamine as example):

[0034] TiCl 4 +4iPrOH+4HNEt 2 →Ti(OiPr) 4 +4NEt 2 h 2 · Cl

[0035] The inventor found by accident in the process of studying the process scheme of titanium tetraisopropoxide that replacing traditional ammonia with dialkylamine can better match the reaction process of titanium tetrachloride and isopropanol. The carrying out of the reaction of titanium tetrachloride and isopropanol, the hydrochlori...

Embodiment 1

[0048] Present embodiment is a kind of preparation method of titanium tetraisopropoxide, and the steps are as follows:

[0049] (1) Under the protection of nitrogen, the TiCl 4 (151.2g, 0.8mol) and isopropanol (192g, 3.2mol) were stirred evenly in n-hexane (1L), and placed in a low-temperature cold bath at 0°C;

[0050] (2) Add diethylamine (351g, 4.8mol) dropwise to the reaction system of step (1), which takes 30min, that is, the addition rate of said diethylamine is 9.6mol / h;

[0051] (3) After the reaction system of step (2) continued to react for 1 hour, under the protection of nitrogen, suction filtration was obtained to obtain the filtrate, and the solvent was distilled off under reduced pressure at 30° C. to obtain 216 g of crude product, with a yield of 95%;

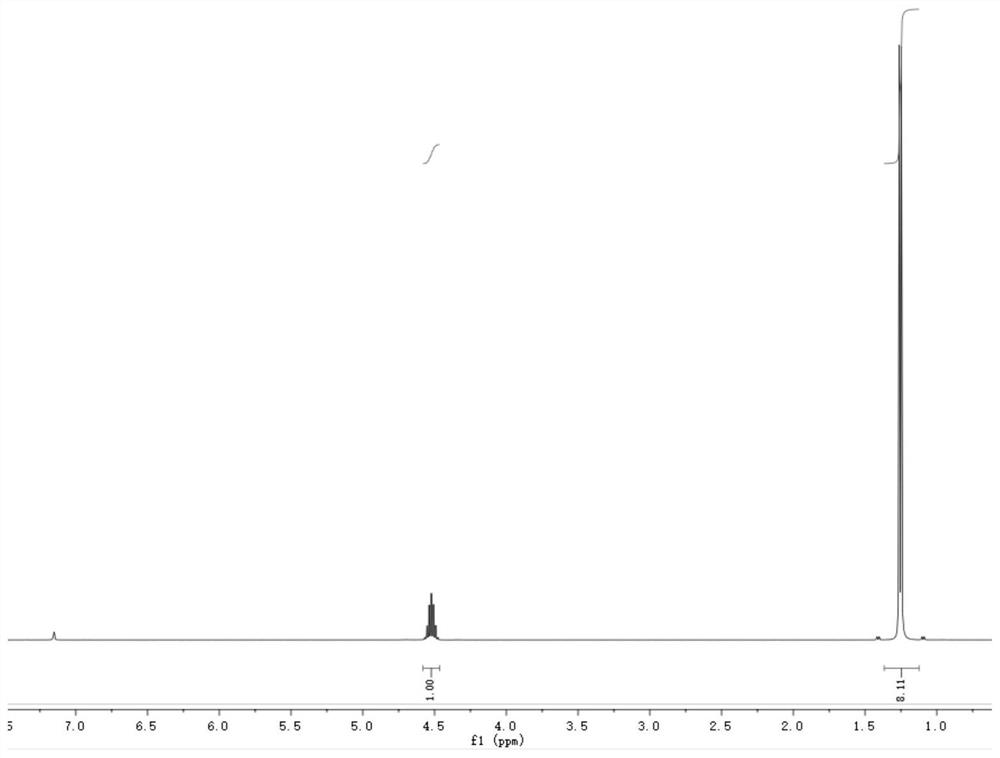

[0052] (4) Purify the filtrate by distillation under a vacuum of 0.1 Torr, collect fractions at 62 to 65° C., and obtain titanium tetraisopropoxide (193 g, 0.68 mol) with a yield of 85%, which is a colorless tra...

Embodiment 2

[0055] This embodiment is a preparation method of titanium tetraisopropoxide, the steps of which are basically the same as those in Example 1, the main difference being that the amount of diethylamine added dropwise in step (2) is 234 g, 3.2 mol.

[0056] The specific technical scheme is as follows:

[0057] (1) Under the protection of nitrogen, the TiCl 4 (151.2g, 0.8mol) and isopropanol (192g, 3.2mol) were stirred evenly in n-hexane (1L), and placed in a low-temperature cold bath at 0°C;

[0058] (2) Add diethylamine (234g, 3.2mol) dropwise to the reaction system of step (1), which takes 20min, that is, the addition rate of said diethylamine is 9.6mol / h;

[0059] (3) After the reaction system of step (2) continued to react for 1 hour, under the protection of nitrogen, suction filtration was performed to obtain the filtrate, and the solvent was distilled off under reduced pressure at 30° C. to obtain 200 g of crude product with a yield of 88%;

[0060] (4) Distill and purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com