Method for preparing dendritic rubrene crystal film by utilizing polylactic acid

A technology of rubrene and polylactic acid, applied in crystal growth, chemical instruments and methods, single crystal growth and other directions, can solve the problems of difficult control of crystal size of rubrene crystal thin film, difficult control of crystal size, complicated preparation process and the like, Achieve the effect of improving carrier mobility, easy industrialization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

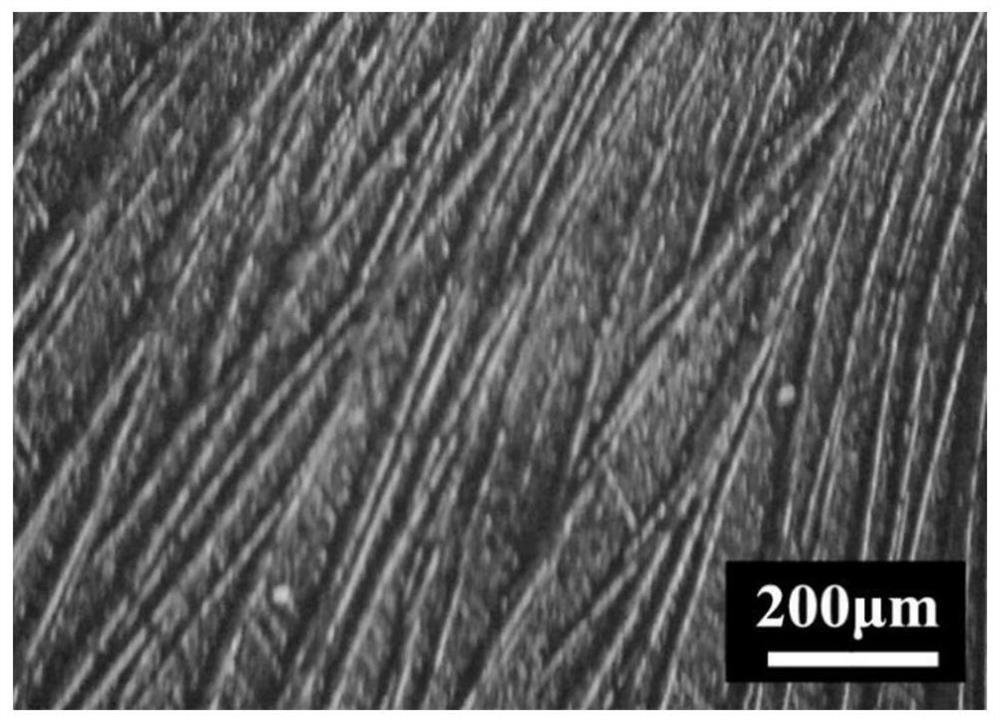

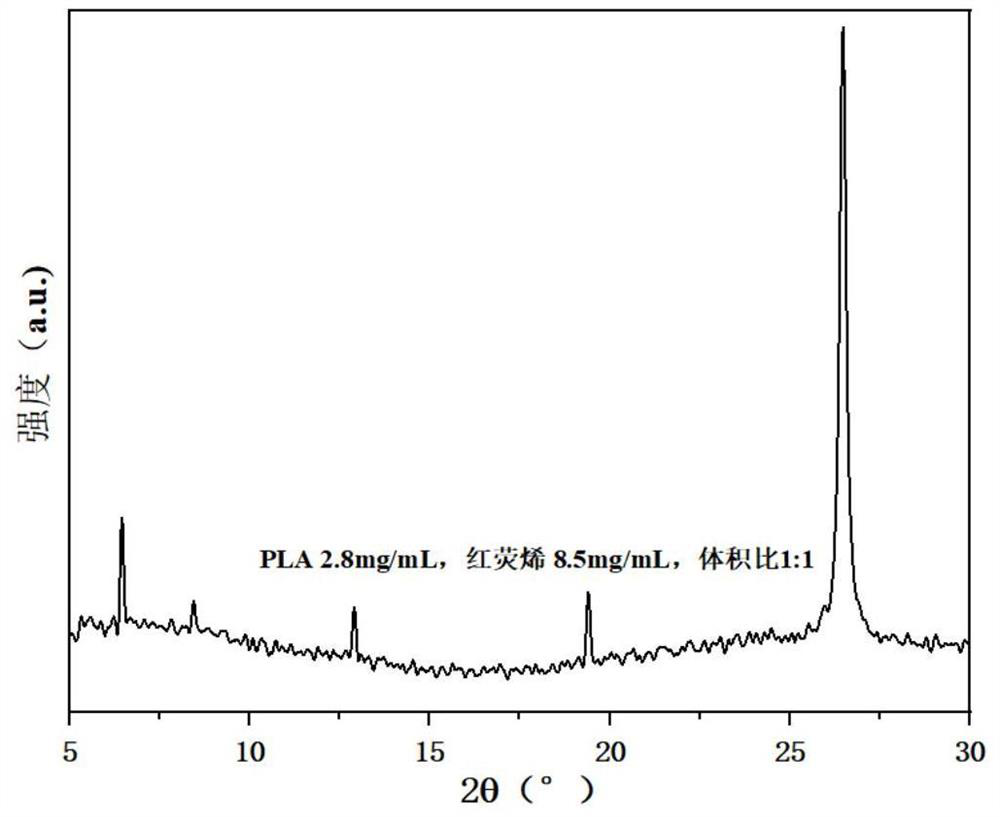

[0041] A kind of method utilizing polylactic acid to prepare dendritic rubrene crystal film, comprises following preparation steps:

[0042] 1) First, take polylactic acid and add chloroform to prepare a 2.8mg / mL polylactic acid solution;

[0043]2) Under dark room conditions, take rubrene and add chloroform to prepare 8.5 mg / mL rubrene solution, then mix the two at a volume ratio of 1:1, and oscillate for 30 minutes to mix evenly;

[0044] 3) Under darkroom conditions, spin coat the mixed solution obtained in step 2) onto the FTO conductive glass with a homogenizer to form a thin film. 1cm*1cm in size, use appropriate amount of acetone, absolute ethanol, and deionized water to ultrasonically clean for 15 minutes. The model of the homogenizer is: KW-4A Institute of Microelectronics, Chinese Academy of Sciences (Beijing);

[0045] 4) Under darkroom conditions, place the FTO conductive glass with rubrene film obtained in step 3) on a hot stage at 110°C and keep it warm for 50s;...

Embodiment 2

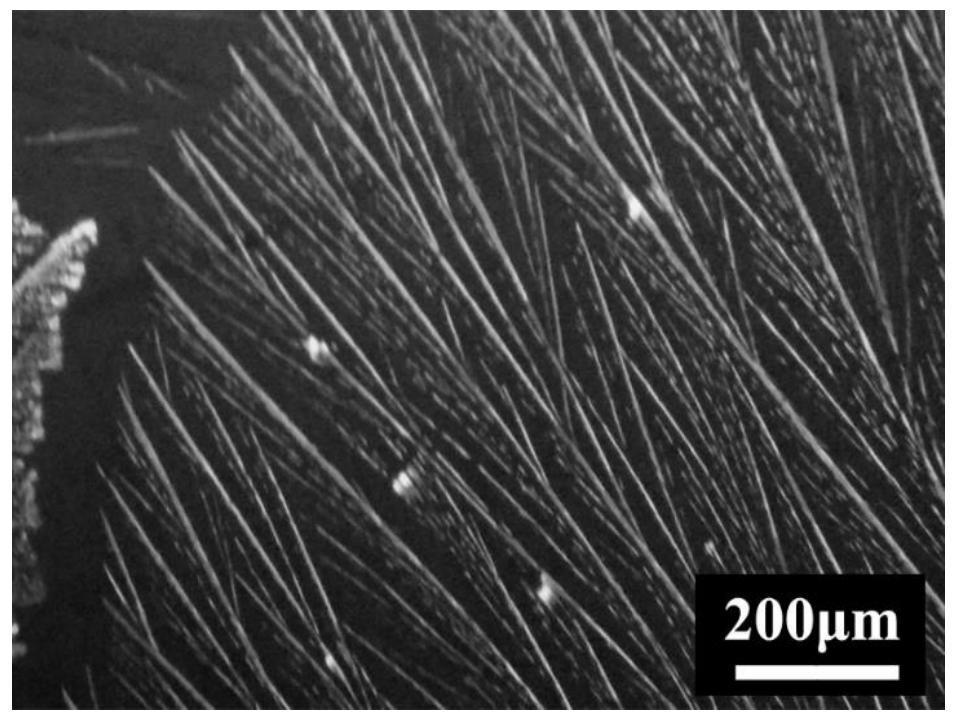

[0049] A kind of method utilizing polylactic acid to prepare dendritic rubrene crystal film, comprises following preparation steps:

[0050] 1) First, take polylactic acid and add chloroform to prepare a 3mg / mL polylactic acid solution;

[0051] 2) Under dark room conditions, take rubrene and add chloroform to prepare 9 mg / mL rubrene solution, then mix the two at a volume ratio of 1:1, and oscillate for 30 minutes to mix evenly;

[0052] 3) Under darkroom conditions, spin-coat the mixed solution obtained in step 2) onto the FTO conductive glass to form a thin film with a spin coating parameter of 2400r / min and 40s; the FTO conductive glass is cut into 1cm before use. *1cm in size, use appropriate amount of acetone, absolute ethanol, and deionized water to ultrasonically clean for 15 minutes. The model of the homogenizer is: KW-4A Institute of Microelectronics, Chinese Academy of Sciences (Beijing);

[0053] 4) Under darkroom conditions, place the FTO conductive glass with rub...

Embodiment 3

[0057] A kind of method utilizing polylactic acid to prepare dendritic rubrene crystal film, comprises following preparation steps:

[0058] 1) First, take polylactic acid and add chloroform to prepare a 3.4mg / mL polylactic acid solution;

[0059] 2) Under dark room conditions, take rubrene and add chloroform to prepare 8.8 mg / mL rubrene solution, then mix the two at a volume ratio of 1:1, and mix them evenly by ultrasonic oscillation for 30 minutes;

[0060] 3) Under darkroom conditions, spin-coat the mixed solution obtained in step 2) onto the FTO conductive glass to form a thin film with a spin coating parameter of 2300r / min and 40s; the FTO conductive glass is cut into 1cm before use. *1cm in size, use appropriate amount of acetone, absolute ethanol, and deionized water to ultrasonically clean for 15 minutes. The model of the homogenizer is: KW-4A Institute of Microelectronics, Chinese Academy of Sciences (Beijing);

[0061] 4) Under darkroom conditions, place the FTO con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com