Thickening and stabilizing agent, and solvent composition by using same for production of electronic device

A technology of solvent composition and electronic equipment, applied in the direction of preparation of non-polymer adhesive additives, adhesive additives, organic compounds, etc., can solve the problem of inability to adjust the degree of gelation, and the viscosity increase of fluid organic substances has not been found and other problems, to achieve the effect of not easy liquid sagging, reducing residual amount, and good coating property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] Example 1

[0131] Methyl behenate (20.0 g, 56.4 mmol) and ethylenediamine (16.9 g, 281 mmol) were stirred at 110° C. for 18 hours, and the reactant was washed with methanol, followed by filtration. The filtrate was subjected to solvent distillation, and the obtained residue was purified by recrystallization using hexane. N-Docosylethylenediamine was obtained as white crystals (yield 65%, 14.0 g, 36.7 mmol).

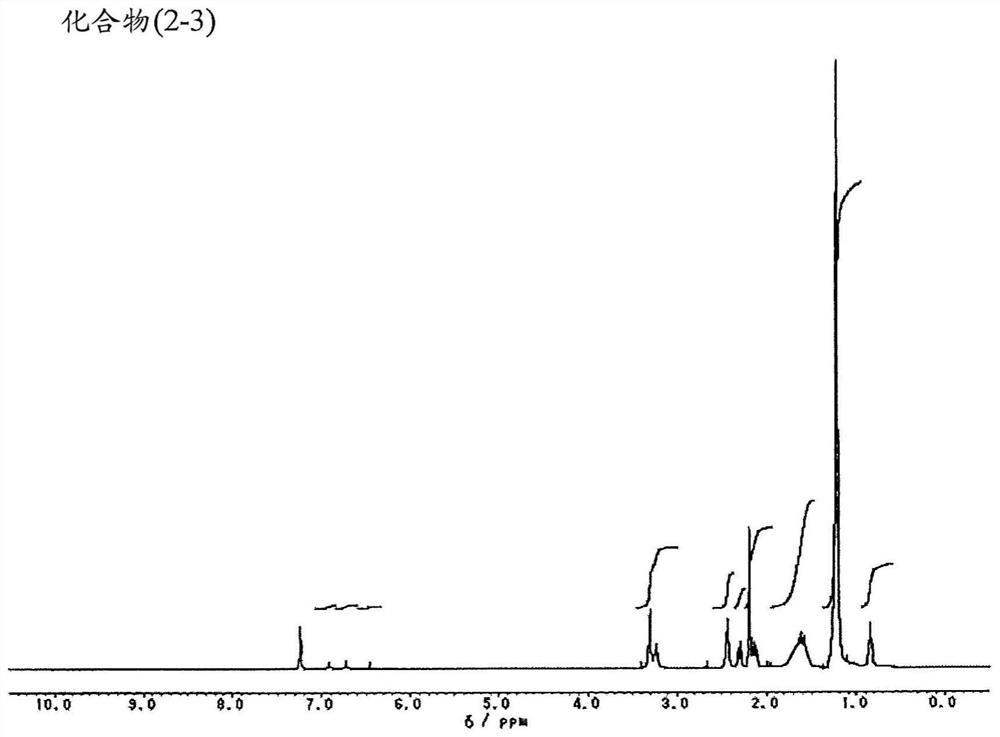

[0132] In N-dimethylformamide (40ml) solution, spent 10 minutes to add N-docosylethylenediamine (12.0g, 31.4mmol) and triethylamine (6.35g, 62.8mmol), succinic anhydride ( 3.45 g, 34.5 mmol), stirred at 100° C. for 15 minutes. After dissolving succinic anhydride, acetic anhydride (4.81 g, 47.1 mmol) was added dropwise to the crude reaction liquid over 10 minutes, followed by stirring at 100° C. for 1 hour. The reaction mixture was poured into water (200 ml), and the precipitate was filtered and washed with water. The precipitate was purified by recrystallizat...

Embodiment 2

[0139] Example 2

[0140] N-Docosylaminoethylsuccinimide was obtained by the same method as in Example 1.

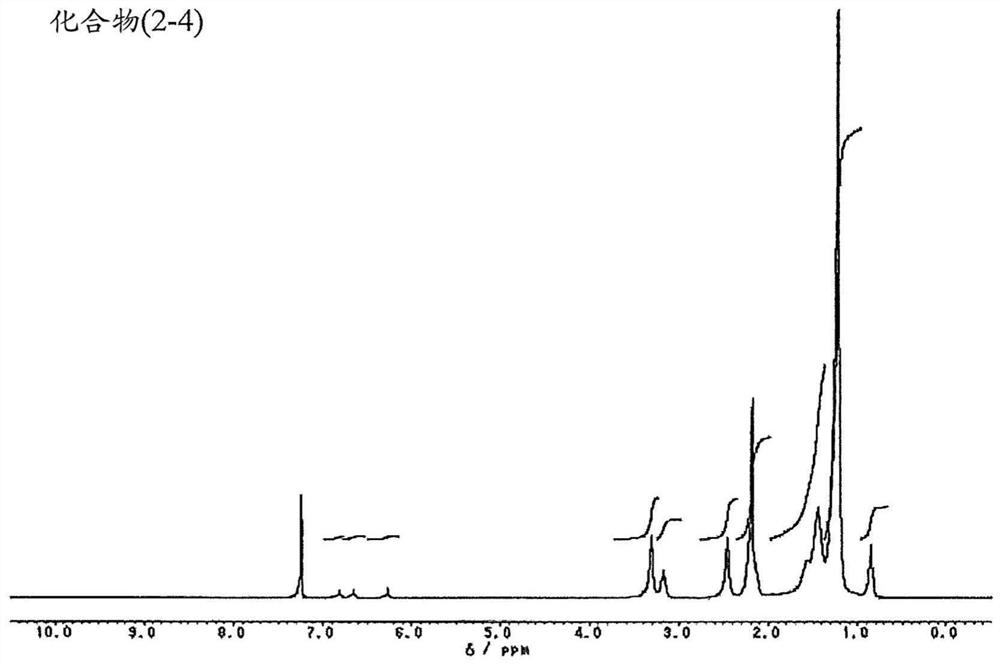

[0141] The obtained N-docosylaminoethylsuccinimide (8.00 g, 17.2 mmol) and hexamethylenediamine (10.0 g, 86.1 mmol) were stirred at 120° C. for 18 hours. The reaction mixture was poured into methanol, and the precipitate was filtered and washed with methanol. The resulting solid was purified using acetonitrile, methanol and by recrystallization. N-(behenylaminoethyl)aminosuccinamidoylaminohexylamine was obtained as a white crystalline powder (yield 69%, 6.91 g, 11.9 mmol).

[0142] Dissolve N-(docosylaminoethyl)aminosuccinamidoylaminohexylamine (3.25g, 5.59mmol), 37% aqueous formaldehyde (2.73ml) and formic acid (1.55g, 33.7mmol) in 2-propane Alcohol (15ml), stirred at 100°C for 4 hours. The reaction mixture was poured into 1M aqueous sodium hydroxide solution (20 ml) and the crystals were filtered. The obtained crystals were recrystallized with methanol and aceton...

Embodiment 3

[0148] Example 3

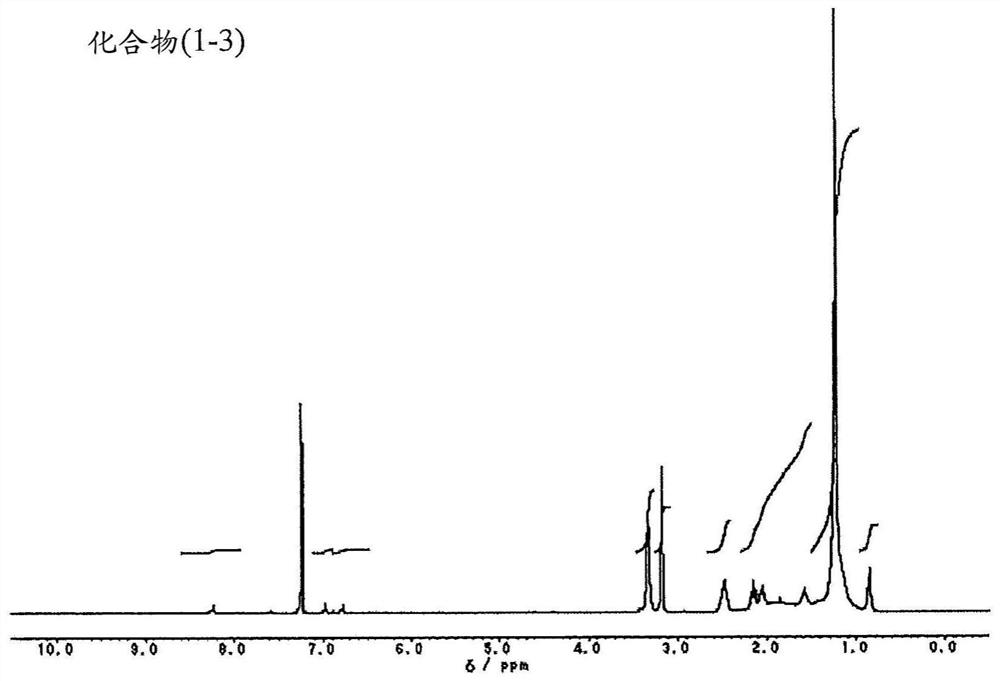

[0149]Methyl eicosanoate (18.0 g, 55.1 mmol) and ethylenediamine (16.5 g, 276 mmol) were stirred at 110° C. for 18 hours, and the reactant was washed with methanol, followed by filtration. The filtrate was subjected to solvent distillation, and the obtained residue was purified by recrystallization using hexane. N-eicosylethylenediamine was obtained as white crystals (yield 68%, 13.3 g, 37.5 mmol).

[0150] In N-dimethylformamide (30ml) solution, spent 10 minutes to add N-eicosylethylenediamine (10.0g, 28.2mmol) and triethylamine (5.71g, 56.4mmol), succinic anhydride (3.10 g, 31.0 mmol), stirred at 100°C for 15 minutes. After dissolving succinic anhydride, acetic anhydride (4.32 g, 42.3 mmol) was added dropwise to the reaction crude liquid over 1 minute, followed by stirring at 100° C. for 1 hour. The reaction mixture was poured into water (150 ml), and the precipitate was filtered and washed with water. The precipitate was purified by recrystallization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com