Beta-SIALON FLUORESCENT BODY AND LIGHT-EMITTING DEVICE

A technology of phosphors and light-emitting elements, applied in the directions of light-emitting materials, optics, semiconductor devices, etc., can solve problems such as poor color reproducibility, achieve stable light-emitting properties, and suppress uneven light-emitting properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Using a V-type mixer, 98.06 wt% of α-type silicon nitride powder (SN-E10 grade, manufactured by Ube Industries, Ltd.), 1.34 wt% of aluminum nitride powder (E grade, manufactured by Tokuyama Co., Ltd.), europium oxide ( RU grade, manufactured by Shin-Etsu Chemical Co., Ltd.) 0.60 wt% was mixed. All of the mixture was passed through a sieve with a mesh size of 250 μm to remove aggregates to obtain raw material mixed powder.

[0054] 250 g of the raw material mixed powder that passed through the sieve was filled into a cylindrical boron nitride container with a cover (N-1 grade manufactured by Denki Kagaku Co., Ltd.), and an electric furnace with a carbon heater was used in a pressurized nitrogen atmosphere of 0.8 MPa. Heat treatment was performed at 2000° C. for 15 hours.

[0055] After cooling, the sample recovered from the furnace was a green lump, which was crushed in a mortar and finally passed through a sieve with a mesh size of 150 μm.

[0056] The obtained phosph...

Embodiment 2~4、 comparative example 1

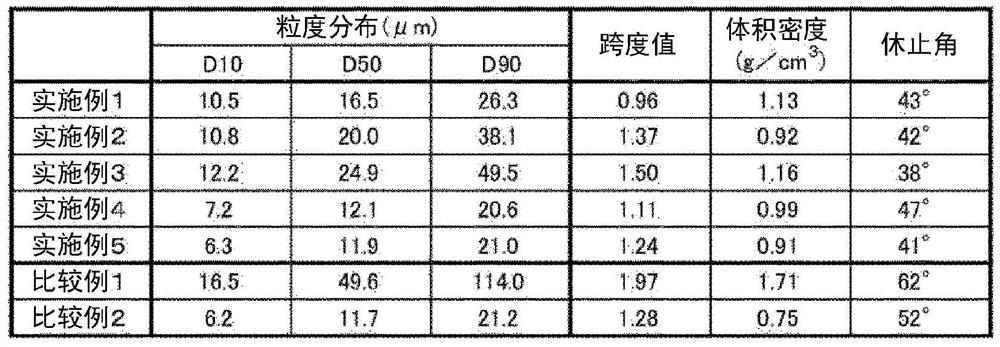

[0066] The pulverization and classification conditions were changed so as to form D10, D50 (mass median particle size), and D90 shown in Table 1, and Examples 2 to 4 and Comparative Example were produced under the same conditions as in Example 1 except that 1 phosphor powder. The properties of the phosphors obtained in Examples 2 to 4 and Comparative Example 1 are shown in Table 1 together with the results of Example 1.

Embodiment 5

[0068] Grinding and classification conditions were changed in such a way as to form D10, D50 (mass median particle size), and D90 shown in Table 1, and cleaning based on ethanol aqueous solution was implemented after pickling. In addition, in the same manner as in Example 1, The phosphor powder of Example 5 was produced under the same conditions. The properties of the phosphor obtained in Example 5 are also shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com