Processing method of rice

A processing method and rice technology, applied in the field of rice processing, can solve problems such as poor storage stability of rice, and achieve the effects of reducing nutrient loss and reducing starch aging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

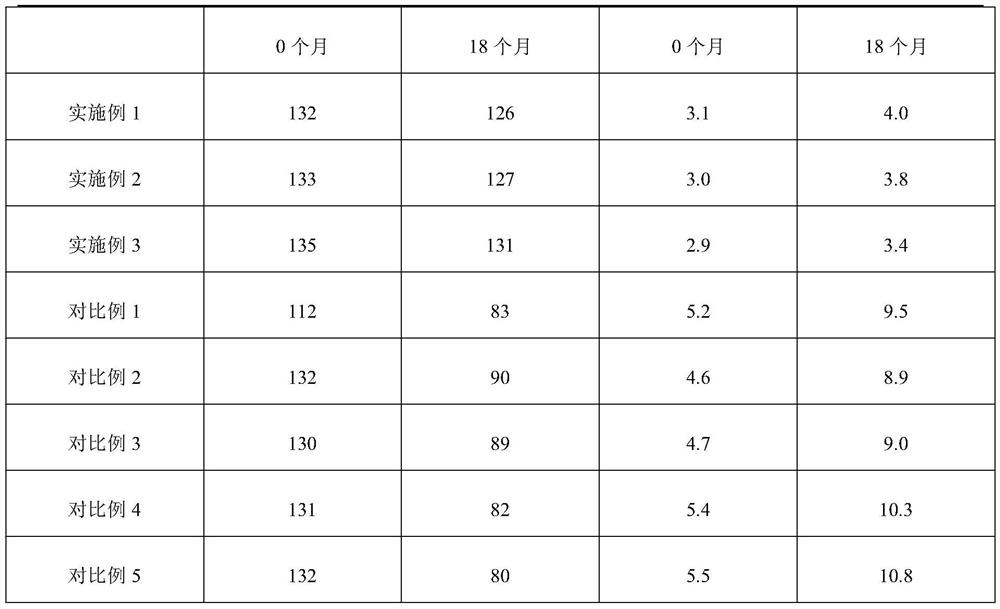

Embodiment 1

[0035] A rice processing method. First, the harvested fresh rice is treated at 75°C for 9 hours, then processed into polished rice, and transferred to a closed container. The nitrogen flow is blown into the nano-zinc oxide whisker until the internal pressure is 5MPa, and the pressure is maintained. Treat for 40 minutes, release the pressure instantly, then separate and remove the nano-zinc oxide whiskers to obtain pretreated polished rice, and finally add the pretreated polished rice to the fermentation broth for ultrasonic oscillation, pulse magnetic field treatment, filter, and air-dry in a drying room until the water content is 15%. , can be packaged; wherein, the preparation method of the fermented liquid is as follows: first inoculate Aureobasidium pullulans and Sclerotinia sclerotinum into a sterilized liquid medium, ferment, and centrifuge to take the supernatant to obtain the fermented liquid.

[0036] The specific process of processing into polished rice is:

[0037] ...

Embodiment 2

[0054] A rice processing method, the fresh harvested rice is first processed at 85°C for 6 hours, then processed into polished rice, transferred to a closed container, nitrogen flow is blown into nano-zinc oxide whiskers, until the internal pressure is 8MPa, and the pressure is kept Treat for 30 minutes, release the pressure instantly, then separate and remove the nano-zinc oxide whiskers to obtain pretreated polished rice, and finally add the pretreated polished rice to the fermentation broth for ultrasonic vibration, pulse magnetic field treatment, filter, and air-dry in a drying room until the moisture content is 16%. , can be packaged; wherein, the preparation method of the fermented liquid is as follows: first inoculate Aureobasidium pullulans and Sclerotinia sclerotinum into a sterilized liquid medium, ferment, and centrifuge to take the supernatant to obtain the fermented liquid.

[0055] The specific process of processing into polished rice is:

[0056] (A) The pressur...

Embodiment 3

[0073] A rice processing method, the fresh harvested rice is first processed at 80°C for 8 hours, then processed into polished rice, transferred to a closed container, nitrogen flow is blown into nano-zinc oxide whiskers, until the internal pressure is 7MPa, and the pressure is maintained. Treat for 35 minutes, release the pressure instantly, then separate and remove the nano-zinc oxide whiskers to obtain pretreated polished rice, and finally add the pretreated polished rice to the fermentation broth for ultrasonic oscillation, pulse magnetic field treatment, filter, and air-dry in a drying room until the moisture content is 15.5%. , can be packaged; wherein, the preparation method of the fermented liquid is as follows: first inoculate Aureobasidium pullulans and Sclerotinia sclerotinum into a sterilized liquid medium, ferment, and centrifuge to take the supernatant to obtain the fermented liquid.

[0074] The specific process of processing into polished rice is:

[0075] (A) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com