Bismuth-based functional material for adsorbing gaseous iodine as well as preparation method and application thereof

A functional material, bismuth-based technology, applied in the field of bismuth-based functional materials adsorbing gaseous iodine and its preparation, can solve the problems of high cost, low adsorption capacity, difficult recovery, etc., and achieve good thermal stability, simple preparation method and process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

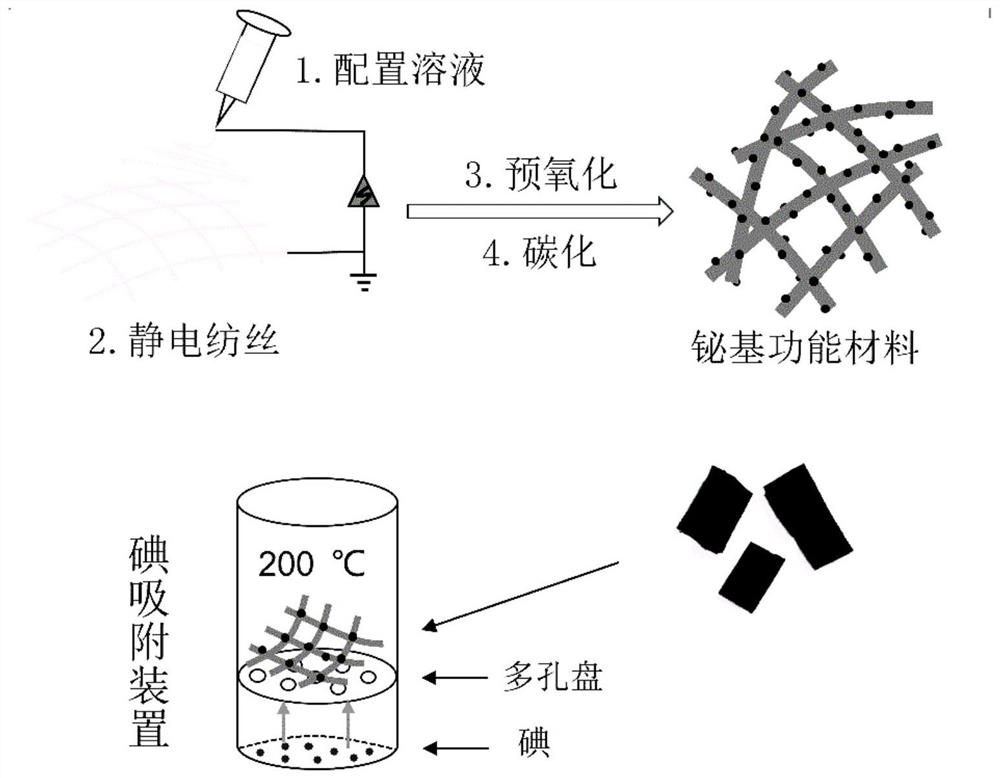

[0043] Schematic diagram of the preparation process of bismuth-based functional materials figure 1 Shown:

[0044] (1) Preparation of precursor solution: Weigh bismuth nitrate pentahydrate, polyacrylonitrile and dimethylformamide at a mass ratio of 0.08:0.10:1, stir to mix them evenly, and obtain a spinning precursor solution;

[0045] (2) Electrospinning: Spin the precursor solution prepared in the above step (1) in an electrospinning machine, the voltage is 24KV, and the spinning rate is 0.010mL / min to obtain a fiber film;

[0046] (3) Pre-oxidation: the fiber membrane prepared in the above step (2) was heated up to 260° C. at a rate of 2° C. / min in an air atmosphere, and kept at this temperature for 2 hours.

[0047] (4) Carbonization: heat up the pre-oxidized fiber membrane prepared in the above step (3) to 800°C at a rate of 5°C / min in an atmosphere of inert gas, and keep it at this temperature for 2h to obtain adsorption Bismuth-based functional materials of gaseous io...

Embodiment 2

[0063] The schematic diagram of the preparation process of bismuth-based functional materials is also as figure 1 Shown:

[0064] (1) Preparation of precursor solution: Weigh bismuth nitrate pentahydrate, polyacrylonitrile and dimethylformamide at a mass ratio of 0.08:0.10:1, stir to mix them evenly, and obtain a spinning precursor solution;

[0065] (2) Electrospinning: Spin the precursor solution prepared in the above step (1) in an electrospinning machine, the voltage is 24KV, and the spinning rate is 0.010mL / min to obtain a fiber film;

[0066] (3) Pre-oxidation: the fiber membrane prepared in the above step (2) was heated up to 260° C. at a rate of 2° C. / min in an air atmosphere, and kept at this temperature for 2 hours.

[0067] (4) Carbonization: heat up the pre-oxidized fiber membrane prepared in the above step (3) to 650°C at a rate of 5°C / min in an atmosphere of inert gas, and keep it at this temperature for 2 hours to obtain adsorption Bismuth-based functional mat...

Embodiment 3

[0070] The schematic diagram of the preparation process of bismuth-based functional materials is also as figure 1 Shown:

[0071] (1) Preparation of precursor solution: Weigh bismuth nitrate pentahydrate, polyacrylonitrile and dimethylformamide according to a mass ratio of 0.06:0.12:1, stir to mix them evenly, and obtain a spinning precursor solution;

[0072] (2) Electrospinning: Spin the precursor solution prepared in the above step (1) in an electrospinning machine, the voltage is 20KV, and the spinning rate is 0.010mL / min to obtain a fiber film;

[0073] (3) Pre-oxidation: the fiber membrane prepared in the above step (2) was heated up to 280° C. at a rate of 2° C. / min in an air atmosphere, and kept at this temperature for 1 hour.

[0074] (4) Carbonization: heat up the pre-oxidized fiber membrane prepared in the above step (3) to 8000°C at a rate of 5°C / min in an atmosphere of inert gas, and keep it at this temperature for 2h to obtain adsorption Bismuth-based functiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com