Simple and pollution-free method for preparing fluoride-free two-dimensional material MXene

A two-dimensional material, non-polluting technology, applied in the field of nanomaterials, can solve the problems of unfavorable MXene industrialization, serious environmental pollution, shallow etching depth, etc., and achieve the effects of low cost, high purity, and reduced reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

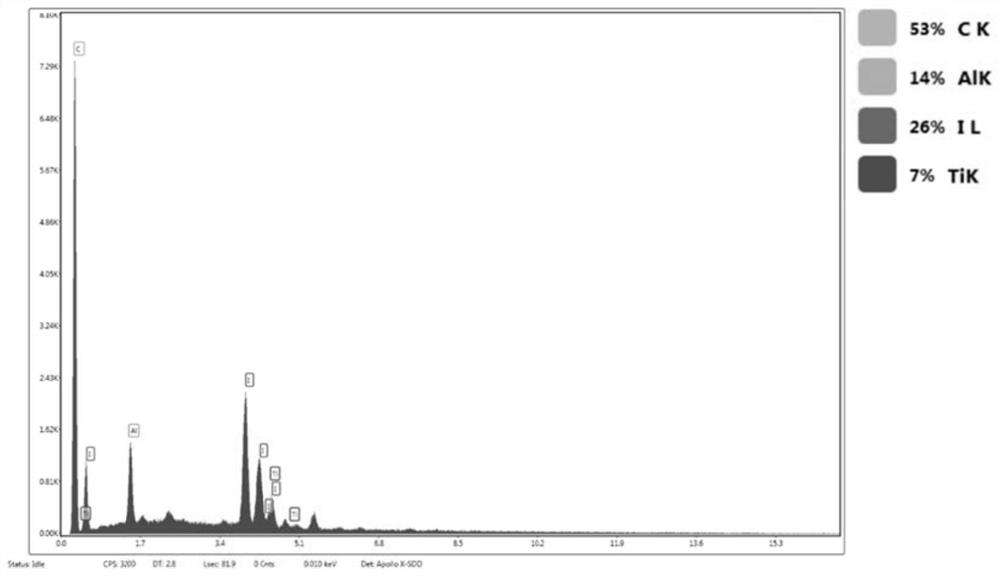

[0046] Such as figure 1 As shown, weigh 10g of iodine element and 0.1g of Ti 3 After the AlC is mixed evenly, it is transferred to a tube furnace, 10Mpa, and treated in an Ar atmosphere at 500°C for 6h. After the reaction is complete, 300°C is passed into an Ar cycle gas for 2h to remove AlI. 3 and iodine vapor, and then cooled naturally. Ready-made MXene two-dimensional material nanosheets.

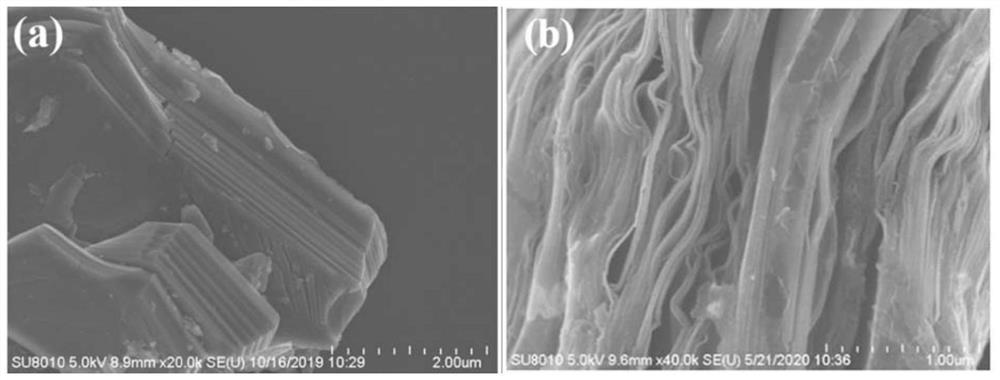

[0047] figure 1 is Ti in Example 1 3 AlC (a) and the prepared MXene two-dimensional material (b) scanning electron microscope (SEM) morphology and size characteristics. Such as figure 1 As shown in (a), MAX presents a thick bulk structure with a thickness of about 1 μm. Selective Redox Etching of Ti by High Temperature Iodine Vapor 3 The interphase Al layer of AlC makes its layered structure get peeled off. Such as figure 1 As shown in (b), the as-prepared MXene presents an ultrathin lamellar structure with a single-layer lamellar thickness of about 10 nm.

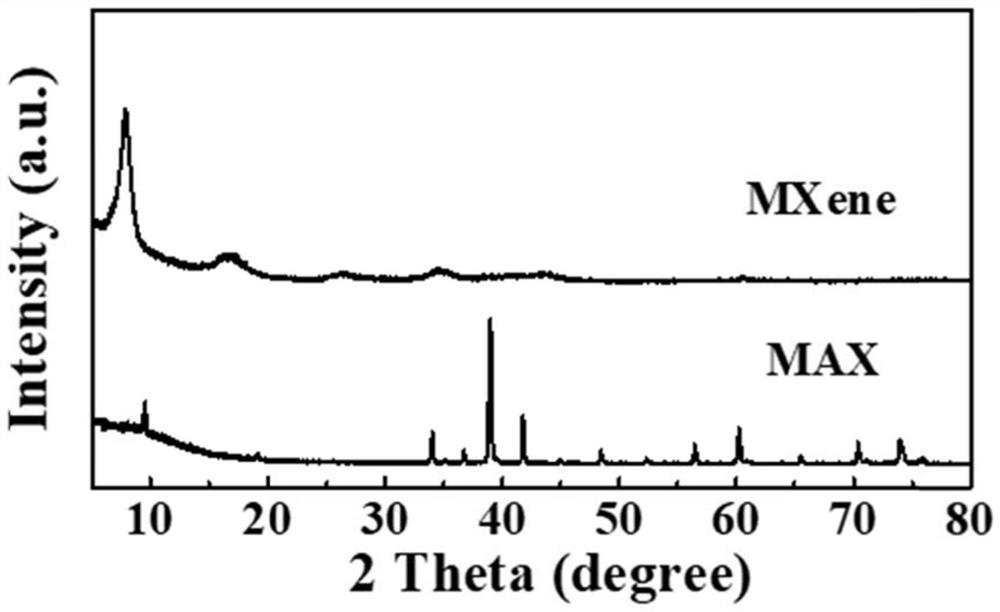

[0048] figure 2 i...

Embodiment 2

[0051] Weigh 5g of iodine element and 0.1g of V 2 After the AlC is mixed evenly, it is transferred to a tube furnace, and treated at 200°C for 24h in a 2Mpa He atmosphere. After the reaction is complete, a He cycle gas is introduced at 200°C for 2h to remove AlI. 3 and iodine vapor, and then cooled naturally. Ready-made MXene two-dimensional material nanosheets. Figure 4 It is the scanning electron microscope (SEM) shape size feature of the prepared MXene two-dimensional material in example 2. The as-prepared MXene exhibits an ultrathin lamellar structure.

Embodiment 3

[0053] Weigh 17g of BI 3 and 0.1 g of Ti 2 After the AlN is mixed evenly, transfer it to a tube furnace, 5Mpa, and treat it in a vacuum atmosphere at 800°C for 4h. After the reaction is complete, continue vacuuming at 900°C for 2h to remove AlI 3 and iodine vapor, and then cooled naturally. Ready-made MXene two-dimensional material nanosheets. Figure 5 It is the scanning electron microscope (SEM) shape size feature of the prepared MXene two-dimensional material in example 3. The as-prepared MXene exhibits an ultrathin lamellar structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com