Spray granulation method and preparation method of microwave dielectric powder for filter

A technology of spray granulation and microwave medium, applied in the field of ceramic materials, can solve problems such as easy cracking, high pressure, and easy sticking of green bodies to molds, so as to improve strength and plasticity, reduce molding pressure, improve fluidity and formability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

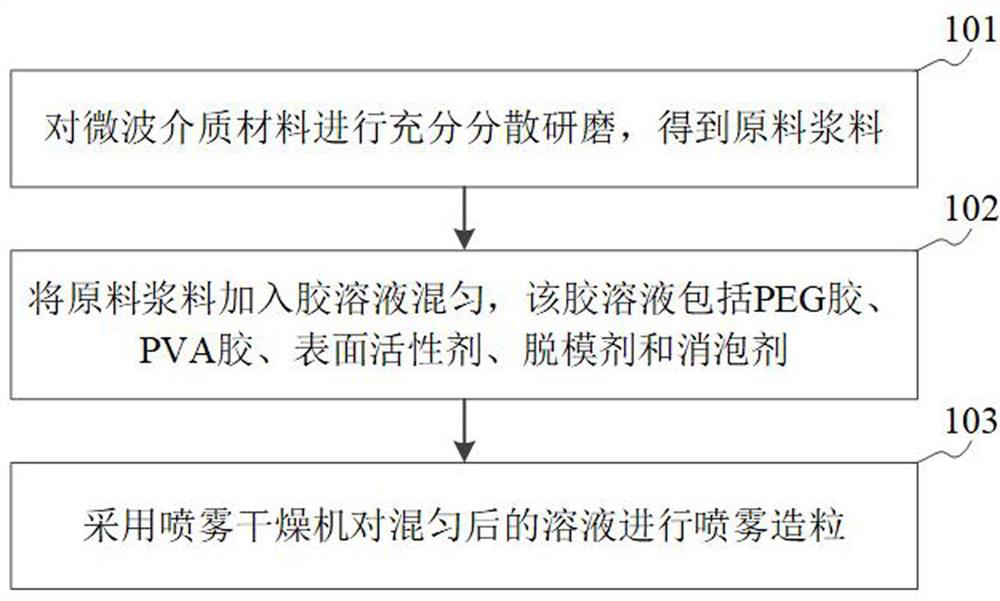

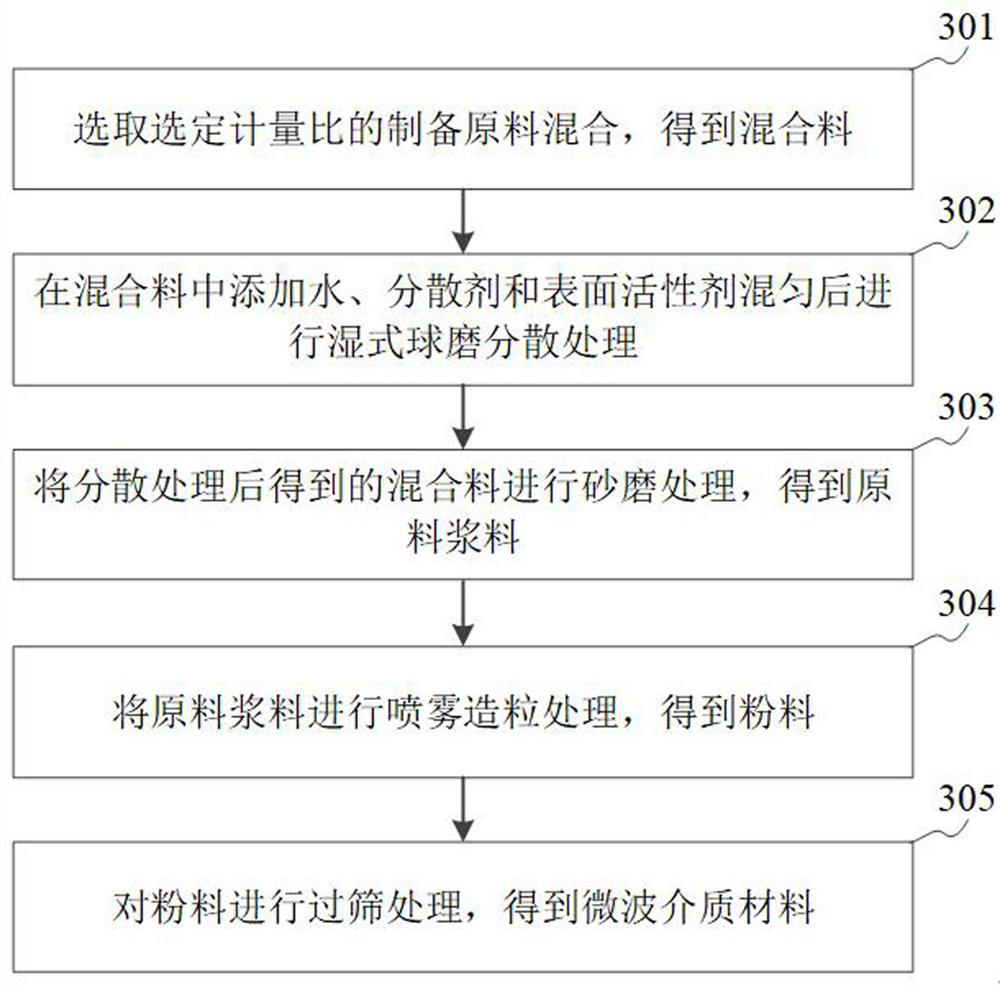

[0051] Please refer to image 3 , Which shows a method for preparing a microwave dielectric material for a filter provided by an embodiment of the present invention, and the method includes:

[0052] In step 301, the preparation raw materials of the selected metering ratio are selected and mixed to obtain a mixture.

[0053] Among them, the preparation raw materials include Mg2SiO4-based microwave dielectric materials or Mg-Ti system microwave dielectric materials. If the preparation raw materials include Mg2SiO4-based microwave dielectric materials, the raw materials containing Mg2SiO4 as the main component can be mixed with modified additives to obtain a mixture; if the preparation raw materials include Mg-Ti system microwave dielectric materials, Mg-Ti can be used The raw material of the main component is mixed with modified additives to obtain a mixture.

[0054] In step 302, water, dispersant and surfactant are added to the mixture, and the mixture is uniformly mixed and subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com