Modified butadiene rubber, composite material and preparation method thereof

A technology of butadiene rubber and composite materials, which is applied in the field of rubber composite materials, and can solve the problems of regularity reduction, change, and complex modification process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Preparation of epoxy myrcene: first myrcene is completely dissolved in dichloromethane, put in the refrigerator and freeze for 2h to take out, slowly add m-chloroperoxybenzoic acid (m- CPBA), return to room temperature, TLC monitors the reaction until the reaction of the raw material is complete, add 2M aqueous sodium hydroxide solution to neutralize the excess acid, extract with dichloromethane and water, anhydrous magnesium sulfate handles the organic phase, then filters and distills under reduced pressure, finally Separation and purification by column chromatography yielded a colorless transparent liquid with a yield of 83.1%.

[0065] 1 H NMR (400MHz, CDCl 3 ):6.38(1H),5.27(1H),5.07(3H),2.76(1H),2.44(1H),2.32(1H),1.77-1.73(2H),1.31(3H),1.26(3H).

[0066] 13 C NMR (100MHz, CDCl 3 ): 145.5, 138.6, 116.1, 113.4, 64.1, 58.4, 28.1, 27.6, 24.9, 18.8.

[0067] (2) Preparation of pyridyl hydroxy myrcene: adopt epoxy myrcene: 2-mercaptopyridine (formula 1'): sodium ...

Embodiment 2

[0075] (1) preparation of pyridyl hydroxy myrcene: with embodiment 1;

[0076] (2) preparation of pyridyl hydroxy myrcene modified butadiene rubber: with embodiment 1;

[0077] (3) Preparation of composite material: The obtained copolymerized rubber is kneaded, banburyed and vulcanized: 100 parts of rubber, 20 parts of white carbon black, 4 parts of zinc oxide, 2 parts of SA, 1 part of 4010N / A, 1.5 parts of CZ, 0.5 parts of D, 1.5 parts of S; banburying for 20 minutes, kneading for 10 minutes until evenly mixed, and vulcanizing for 40 minutes to obtain a composite material containing 20 parts of polar filler white carbon black;

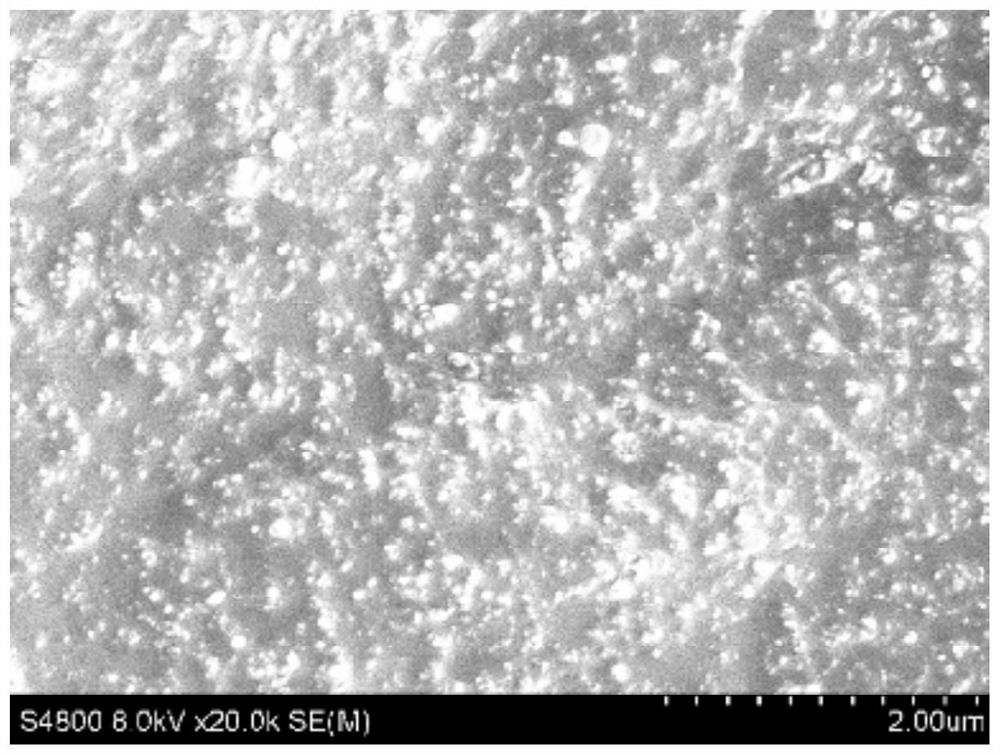

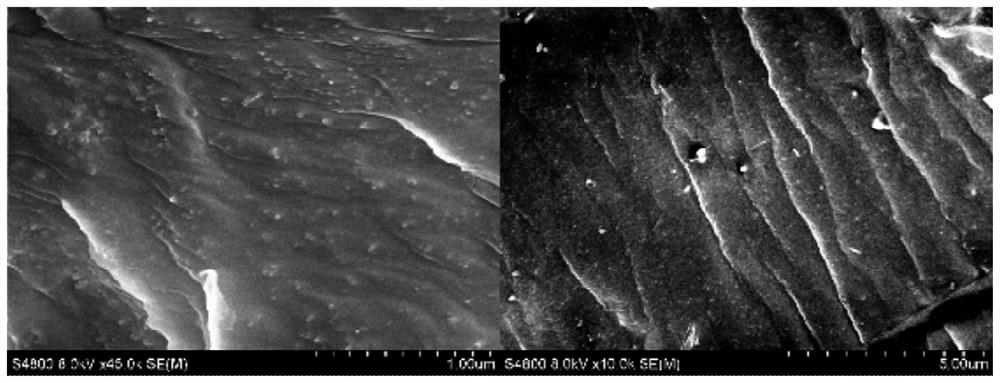

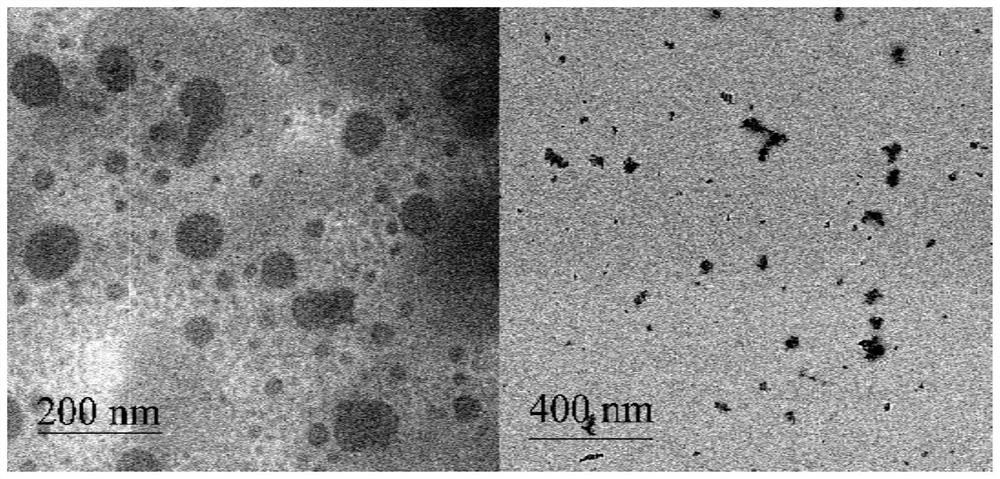

[0078] The composite material was characterized, SEM and TEM showed that the particle size distribution of the filler particles was: 0.01-0.15 μm, the average particle size was 0.12 μm; the mechanical performance test showed that the elongation at break was 580%, and the breaking strength was 6.8MPa, 100 The % elongation strength is 4.2MPa, the 100% ...

Embodiment 3

[0080] (1) preparation of pyridyl hydroxy myrcene: with embodiment 1;

[0081] (2) preparation of pyridyl hydroxy myrcene modified butadiene rubber: with embodiment 1;

[0082] (3) Preparation of composite material: The obtained copolymerized rubber is kneaded, banburyed and vulcanized: 100 parts of rubber, 30 parts of white carbon black, 4 parts of zinc oxide, 2 parts of SA, 1 part of 4010N / A, 1.5 parts of CZ, 0.5 parts of D, 1.5 parts of S; banburying for 20 minutes, kneading for 10 minutes until evenly mixed, and vulcanizing for 40 minutes to obtain a composite material containing 30 parts of polar filler white carbon black;

[0083]Characterize the composite material, SEM and TEM show that the particle size distribution of filler particles is: 0.01~0.35μm, the average particle size is 0.25μm; mechanical properties test shows: the elongation at break is 680%, the breaking strength is 12.1MPa, 100 The % elongation strength is 5.6MPa, the 100% strain storage modulus is 0.21M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com