Method for preparing cluster type aluminum-based composite material from graphene reinforced aluminum-based composite material waste

An aluminum-based composite material and a technology for composite materials, applied in the field of preparing aluminum-based composite materials, can solve the problems that graphene-enhanced aluminum-based composite materials are difficult to recycle and reuse, and achieve easy microstructure design, plasticity improvement, and stress concentration reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

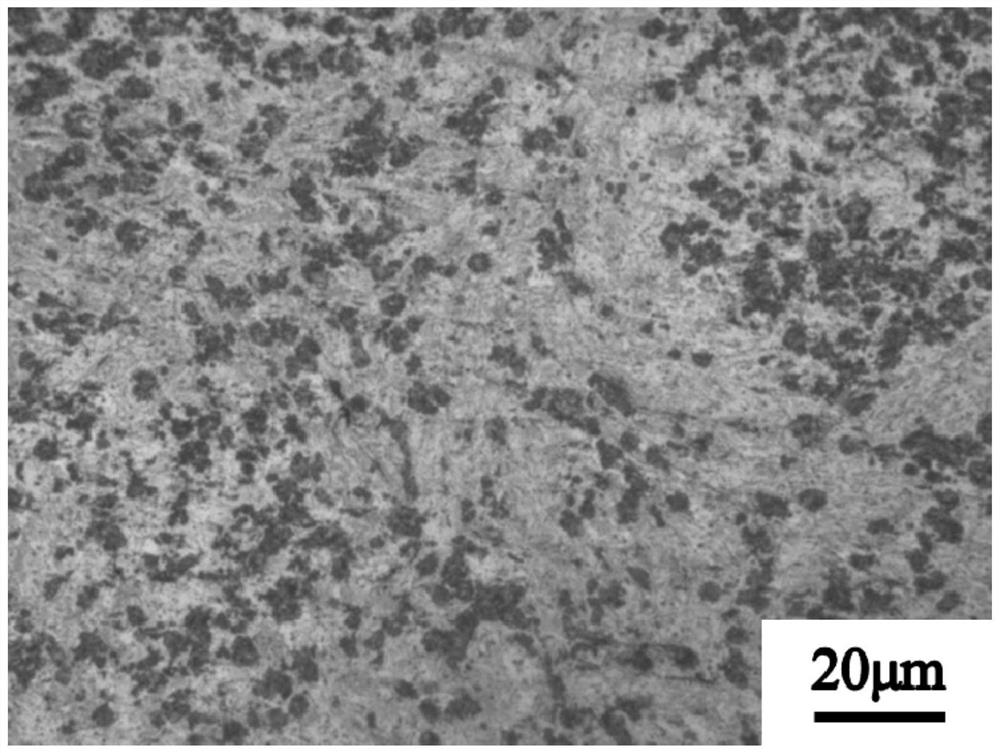

Image

Examples

specific Embodiment approach 1

[0027] Specific implementation mode 1: In this embodiment, the method for preparing a cluster-type aluminum-based composite material by using graphene-reinforced aluminum-based composite material waste is carried out in the following steps:

[0028] 1. Pretreatment of Graphene Reinforced Aluminum Matrix Composites Scrap

[0029] The graphene-reinforced aluminum matrix composite material waste is crushed, and then annealed, cleaned and dried in sequence to obtain pretreated waste particles;

[0030] The annealing process is as follows: heat preservation at 345-355°C for 3.5-4.5 hours, and then cool with the furnace;

[0031] Heat treatment before crushing makes the waste easier to process and reduces the requirements for crushing equipment. Heat treatment of the waste can also make the composition of the material homogeneous, which is beneficial to ensure the uniformity of the subsequent prepared composite material and reduce the problem of material quality degradation due to ...

specific Embodiment approach 2

[0047] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the cleaning process described in step one is: sequentially use alkali builders, surfactants and volatile reagents to carry out the graphene-reinforced aluminum-based composite material waste ultrasonic cleaning;

[0048] The alkali builder is sodium metasilicate pentahydrate, sodium hydroxide, soda ash, etc.;

[0049] The surfactant is alcohol ether phosphate, lauryl amidopropyl amine oxide, etc.;

[0050] Described volatile reagent is alcohol;

[0051] The ultrasonic power for ultrasonic cleaning is 100-500W, and the time is 10-30min.

specific Embodiment approach 3

[0052] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the drying process described in step 1 is: heating to 70-120°C under vacuum or nitrogen atmosphere and keeping it warm for 6-10 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap