Inorganic Si-ZnO-Li composite material, preparation method and application of inorganic Si-ZnO-Li composite material in lithium metal battery

A technology of lithium metal batteries and composite materials, which is applied in the field of energy storage system device materials, can solve problems such as the inability to overcome the infinite volume change of lithium metal negative electrodes, and achieve easy control and realization of reaction conditions, good electrochemical performance, and ease of volume expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing an inorganic Si-ZnO-Li composite material applied to the negative electrode of a lithium metal battery. The specific steps of the method are as follows:

[0035] (1) Preparation of Si-ZnO-Li molten mixture: silicon powder and zinc oxide nanoparticles are mixed with lithium flakes at a mass ratio of 1:1:2, placed in a crucible, heated to 300 ℃, stirred for 30 minutes, and a molten mixture is obtained ;

[0036] (2) Si-ZnO-Li composite material: The Si-ZnO-Li molten mixture obtained in step (1) is cooled to room temperature, and then mechanically pressed into a composite material with uniform thickness.

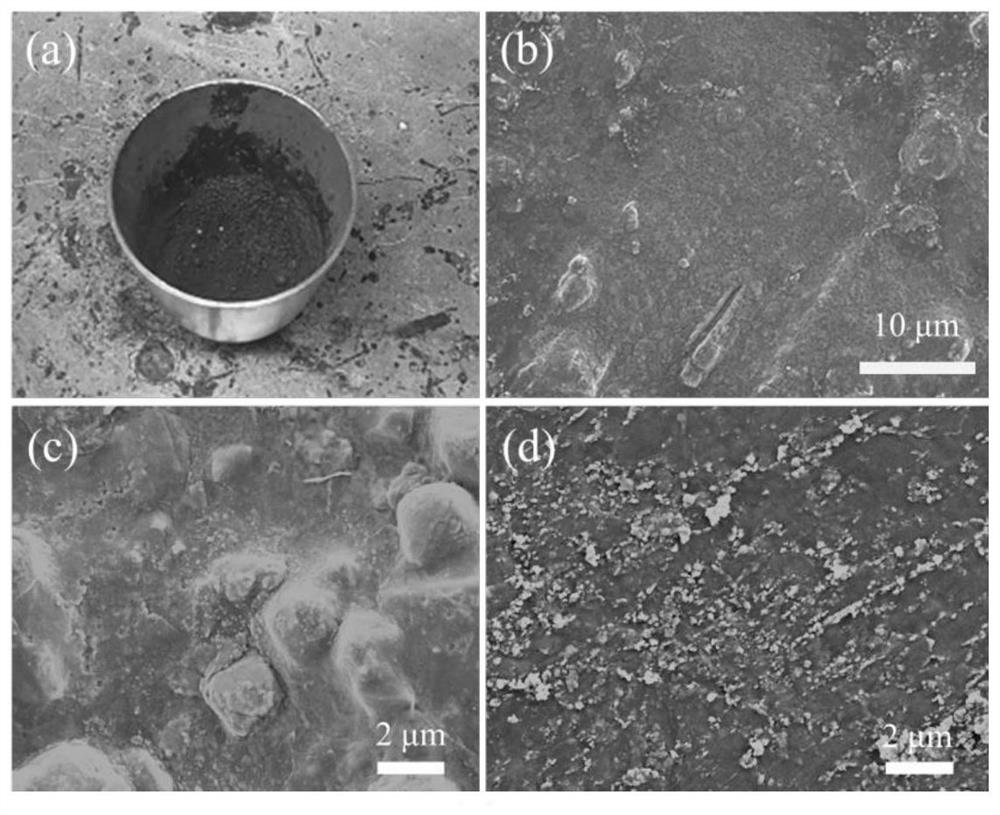

[0037] The composite material prepared in this embodiment cannot be pressed into electrode sheets due to the insufficient amount of Li metal. The digital photos after cooling are shown figure 1 (A).

Embodiment 2

[0039] A method for preparing an inorganic Si-ZnO-Li composite material applied to the negative electrode of a lithium metal battery. The specific steps of the method are as follows:

[0040] (1) Preparation of Si-ZnO-Li molten mixture: silicon powder and zinc oxide nanoparticles are mixed with lithium flakes at a mass ratio of 1.5:1.5:6, placed in a crucible, heated to 300 ℃, stirred for 30 minutes, and a molten mixture is obtained ;

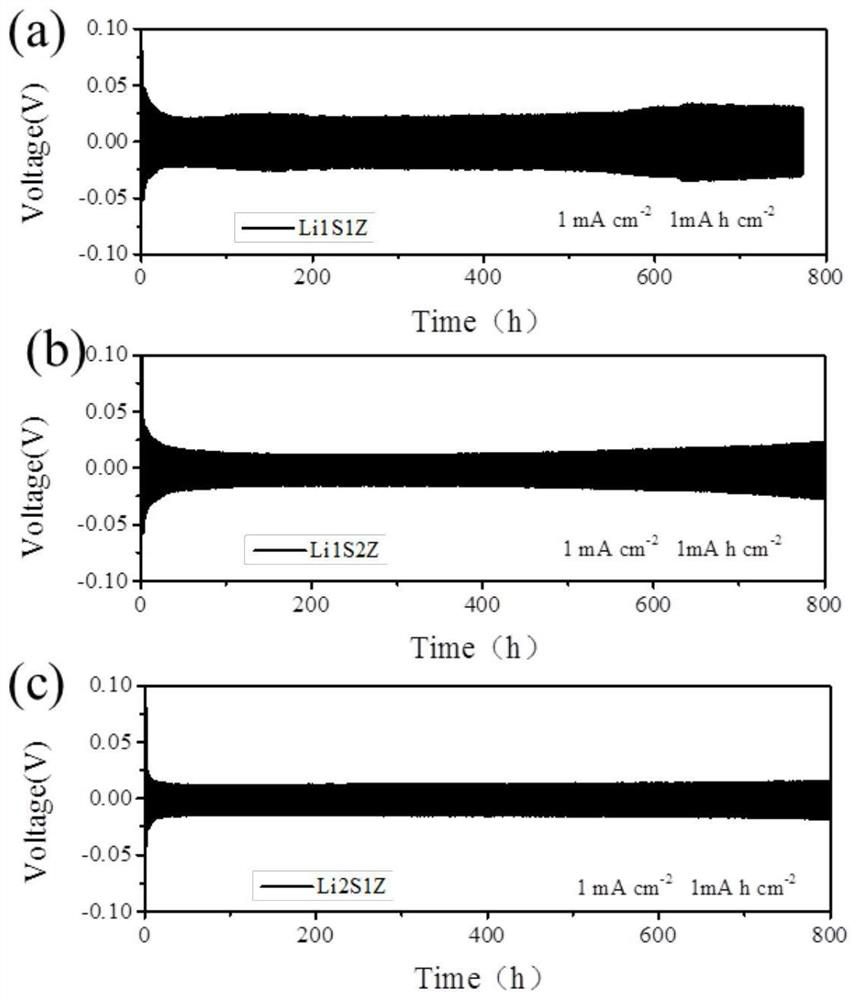

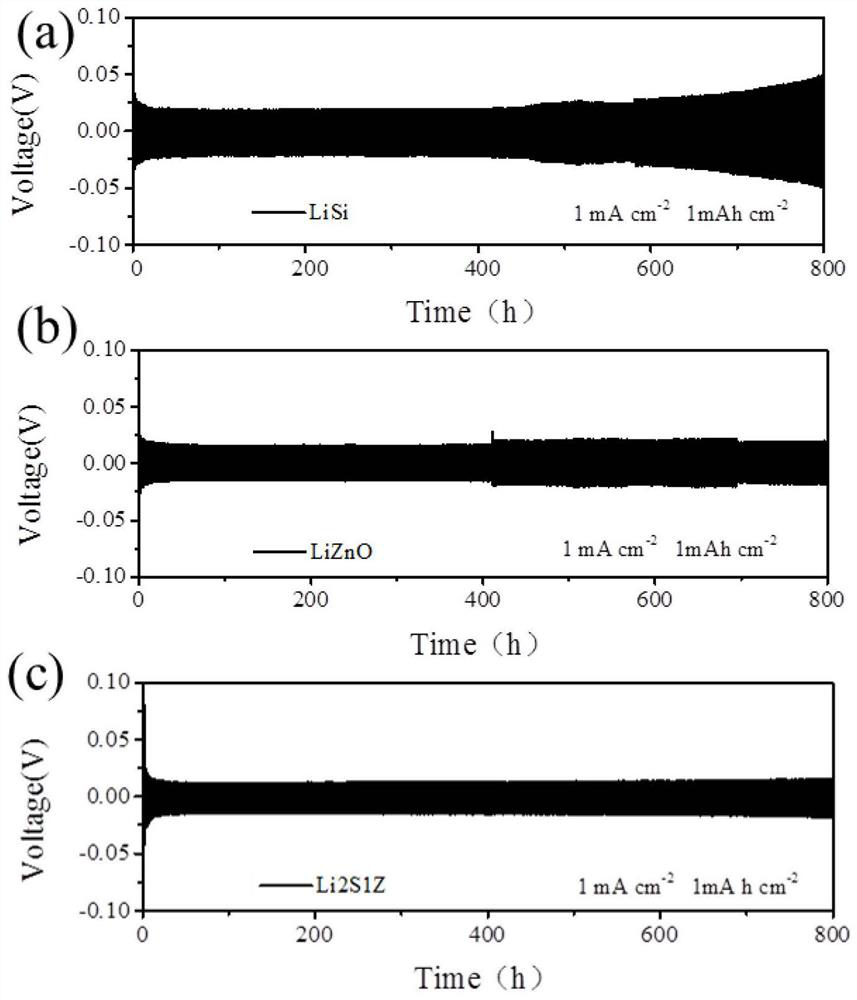

[0041] (2) Si-ZnO-Li composite material: The Si-ZnO-Li molten mixture obtained in step (1) is cooled to room temperature, and then mechanically pressed into a composite material with a thickness of 50-500 μm, which is denoted as Li1S1Z.

Embodiment 3

[0043] A method for preparing an inorganic Si-ZnO-Li composite material applied to the negative electrode of a lithium metal battery. The specific steps of the method are as follows:

[0044] (1) Preparation of Si-ZnO-Li molten mixture: silicon powder and zinc oxide nanoparticles are mixed with lithium flakes in a mass ratio of 1:2:6, placed in a crucible, heated to 300 ℃, stirred for 30 minutes, and a molten mixture is obtained ;

[0045] (2) Si-ZnO-Li composite material: The Si-ZnO-Li molten mixture obtained in step (1) is cooled to room temperature, and then mechanically pressed into a composite material with uniform thickness, which is denoted as Li1S2Z.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com