Lithiated halloysite lithium-sulfur battery positive electrode material and preparation method thereof

A technology of halloysite lithium and positive electrode materials, applied in battery electrodes, lithium batteries, chemical instruments and methods, etc., can solve the problems of poor cycle stability, poor rate performance, slow electrochemical reaction kinetics, etc., and achieve simple process , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Impurity removal of natural halloysite:

[0042]First, the natural halloysite was washed and floated, and 30 g of halloysite was put into 2000 ml of deionized water, and magnetically stirred at room temperature for 24 hours at a stirring speed of 800 rpm. Take the milky white powder suspended in the middle, dry it in the air for 12 hours after suction filtration, and then sieve it with a 200-mesh sieve to obtain halloysite after removal of impurities.

[0043] (2) Lithiation:

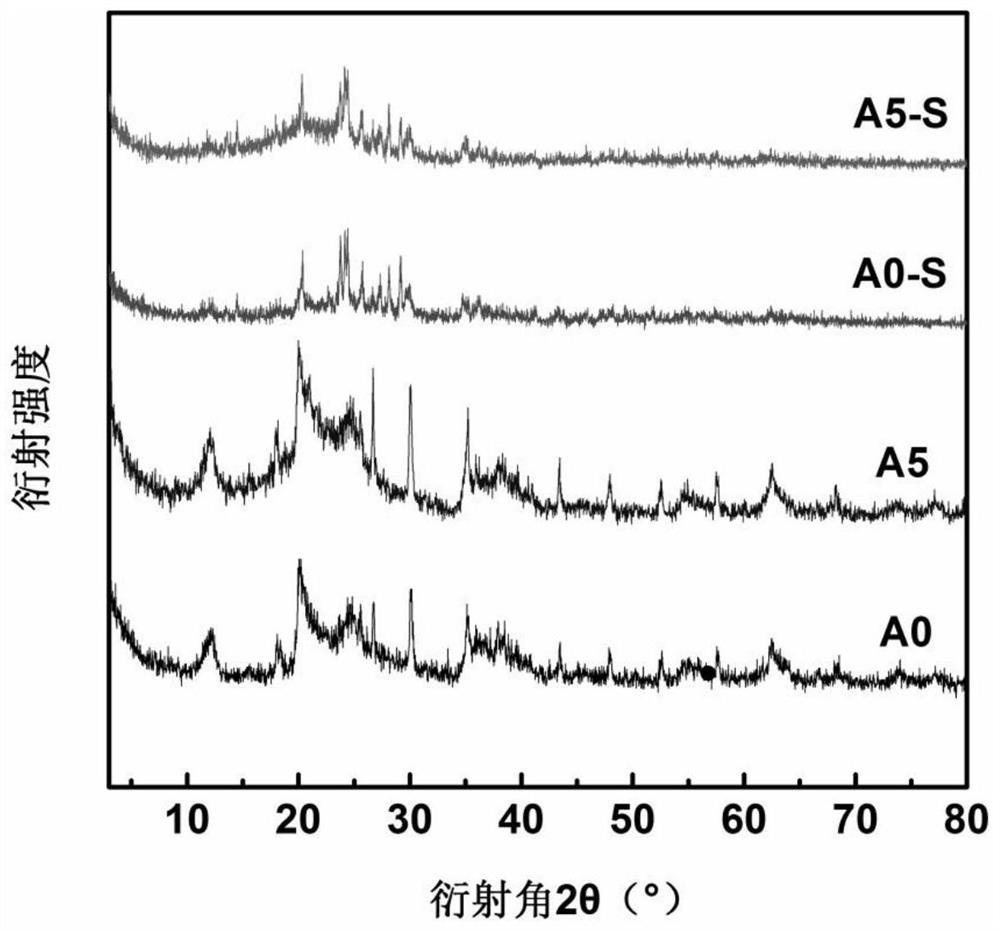

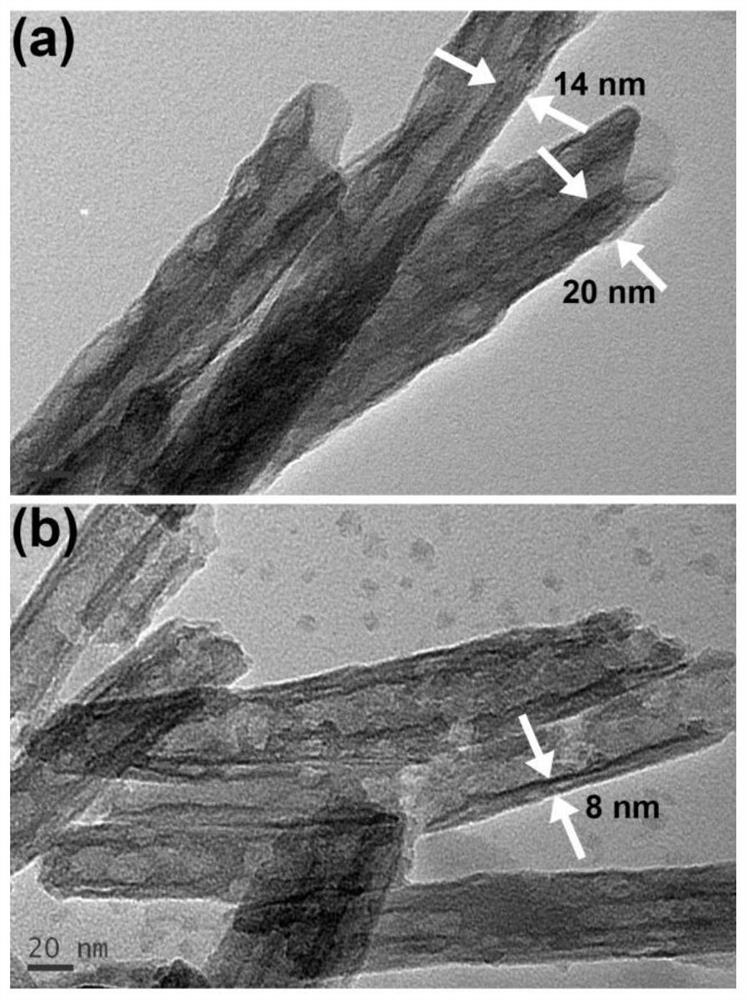

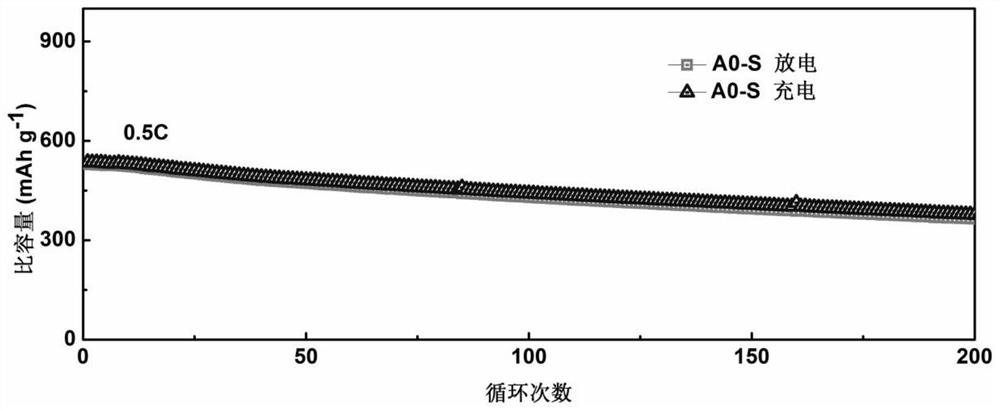

[0044] Take 0.2 g of the sample obtained in the above step (1), put it into 30 ml of LiOH solution with a concentration of 0.5 M, stir at room temperature for 1 h, then suction filter, wash with ethanol several times, and freeze-dry the obtained solid for 24 h to obtain The sample is denoted as A0, see figure 1 X-ray diffraction patterns and figure 2 (a) TEM image, figure 1 The characteristic peak of the A0 sample corresponds to halloysite (the standard card is PDF#09-0453), and also con...

Embodiment 2

[0051] (1) Impurity removal of natural halloysite:

[0052] Step is consistent with embodiment 1;

[0053] (2) Acid etching:

[0054] Get above-mentioned halloysite 1g after impurity removal, add in the sulfuric acid of 100ml, the sulfuric acid concentration is 2M. Stir for 3 hours under heating at 90 degrees, then suction filter, wash repeatedly with deionized water and absolute ethanol until neutral, and dry in a vacuum oven at 60 degrees for 12 hours.

[0055] (3) Lithiation:

[0056] Take 0.2 g of the sample obtained in the above step (2), put it into 30 ml of LiOH solution with a concentration of 1 M, stir at room temperature for 3 h, then suction filter, wash with ethanol several times, and freeze-dry the obtained solid for 24 h to obtain The sample is marked as A3.

[0057] (4) Sulfur loading:

[0058] The steps are the same as in Example 1, and the obtained lithiated halloysite sulfur-loaded material is designated as A3-S.

[0059] (5) Electrochemical test:

[0...

Embodiment 3

[0066] (1) Impurity removal of natural halloysite:

[0067] Step is consistent with embodiment 1;

[0068] (2) Acid etching:

[0069] Get above-mentioned halloysite 1g after impurity removal, add in the sulfuric acid in 100ml, the sulfuric acid concentration is 2M. Stir under heating at 90 degrees for 5 hours, then filter with suction, wash repeatedly with deionized water and absolute ethanol until neutral, and dry in a vacuum oven at 60 degrees for 12 hours.

[0070] (3) Lithiation:

[0071] Take 0.2 g of the sample obtained in the above step (2), put it into a solution of 30 ml of LiOH with a concentration of 2 M, stir at room temperature for 5 h, then filter with suction, wash with ethanol several times, and freeze-dry the obtained solid for 24 h to obtain The sample is marked as A5, see figure 1 In the X-ray diffraction pattern, the characteristic peaks of the A5 sample correspond to halloysite, and also contain some SiO 2 , after acid etching and lithiation, the stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com