Catalytic oxidation filter for organic sulfur waste gas treatment

A technology for catalytic oxidation and waste gas treatment, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of unsuitable biochemical methods, poor oxidation ability, high toxicity, etc., and achieve fast chemical reaction speed and zero waste discharge. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

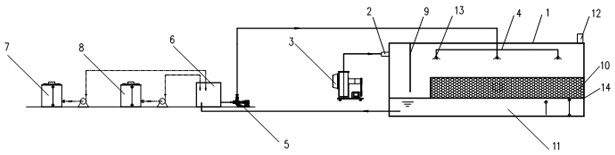

[0031] Such as figure 1 A catalytic oxidation filter for the treatment of organic sulfur waste gas is shown, including a catalytic oxidation packed filter bed box 1, an air inlet 2 of the catalytic oxidation packed filter bed box connected to an exhaust gas storage tank 3, and a catalytic oxidation packed filter bed box The top of the body 1 is provided with a spray pipe 4, the spray pipe 4 is connected to the centrifugal fan 5, the centrifugal fan 5 is connected to the catalytic oxidant dosing device 6 through the pipeline, and the catalytic oxidant dosing device 6 is respectively connected to the hydrogen peroxide through the pipeline Dosing device 7, ferrous sulfate dosing device 8; gas baffles 9 are provided at the air inlet 2 of the catalytic oxidation packed filter bed box body, and gas baffles inside the catalytic oxidation packed filter bed box 1 One side of the baffle plate 9 and the spray pipe 4 are provided with a catalytic filter material layer 10, the bottom of th...

Embodiment 2

[0033] The working process of the catalytic oxidation filter for the treatment of organic sulfur waste gas: the hydrogen peroxide dosing device and the ferrous sulfate dosing device feed the medicament into the catalytic oxidant dosing device, and the proportion is made according to the concentration requirements, and then the catalytic oxidation filler is injected into the catalytic oxidation filler through the centrifugal fan The spray pipe at the top of the filter bed; at the same time, the exhaust gas storage tank feeds the exhaust gas into the catalytic oxidation packed filter bed box, and the exhaust gas first passes through the filter material layer under the action of the baffle plate, and then passes through the chemical spray in the spray head For treatment, the medicament is collected through the liquid collection tank, and the treated waste gas is discharged through the outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com