Harmless oil sediment deoiling system and oil sediment deoiling method

A technology for sediment and deoiling, applied in chemical instruments and methods, hydrocarbon oil treatment, sludge treatment, etc., can solve the problems of difficult to meet the oil content of sand, unstable chemical composition, low treatment efficiency, etc., to reduce costs, Avoid card machine, the effect of high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

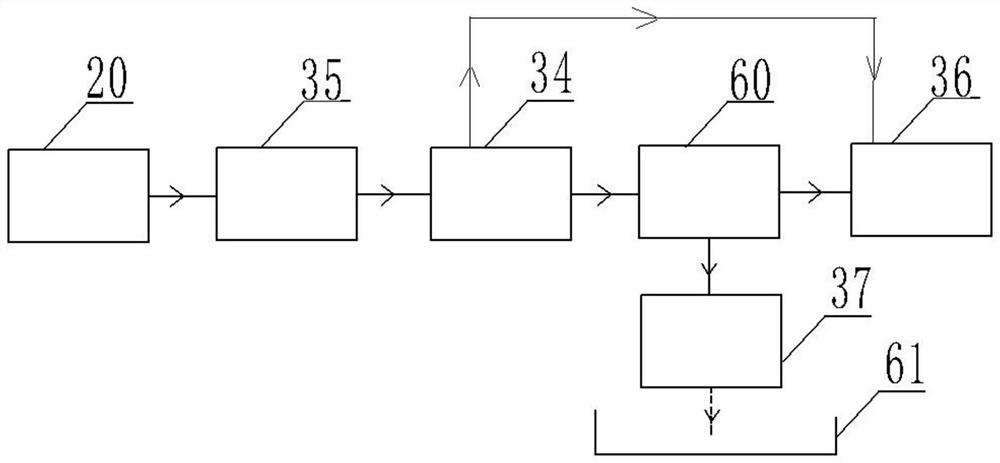

[0066] Such as Figure 1-13As shown, the harmless oil-sludge deoiling system of this embodiment includes a compound feeder 20, a ball mill 35, a swirl heating multi-module unit unit 34, a roller-sand disintegration kettle 60, and a separated oil storage device 36. Horizontal centrifuge 37 and pool 61; the outlet a19 of the compound feeder 20 is connected to the inlet of the ball mill 35 through a pipeline, and the outlet of the ball mill 35 is connected to the swirl heating multi-module unit The feed port b29 of 34 is connected by a pipeline, the discharge port b27 of the swirl heating multi-module unit unit 34 is connected with the feed port c42 of the roller sand-dispelling disintegration kettle 60 by a pipeline, and the shaft drive sand The separated oil outlet 44 of the disintegrating kettle 60 is connected to the separated oil storage device 36 through a pipeline, and the discharge port c45 of the shaft-driven sand disintegrating kettle 60 is connected to the inlet of the...

Embodiment 2

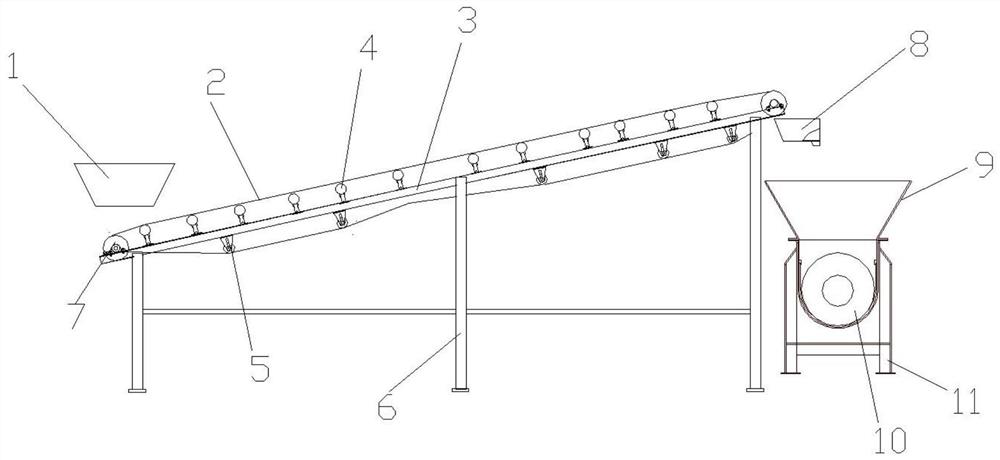

[0074] The present embodiment is the method for deoiling the oily sludge of the harmless oily sludge deoiling system of Example 1, the method is:

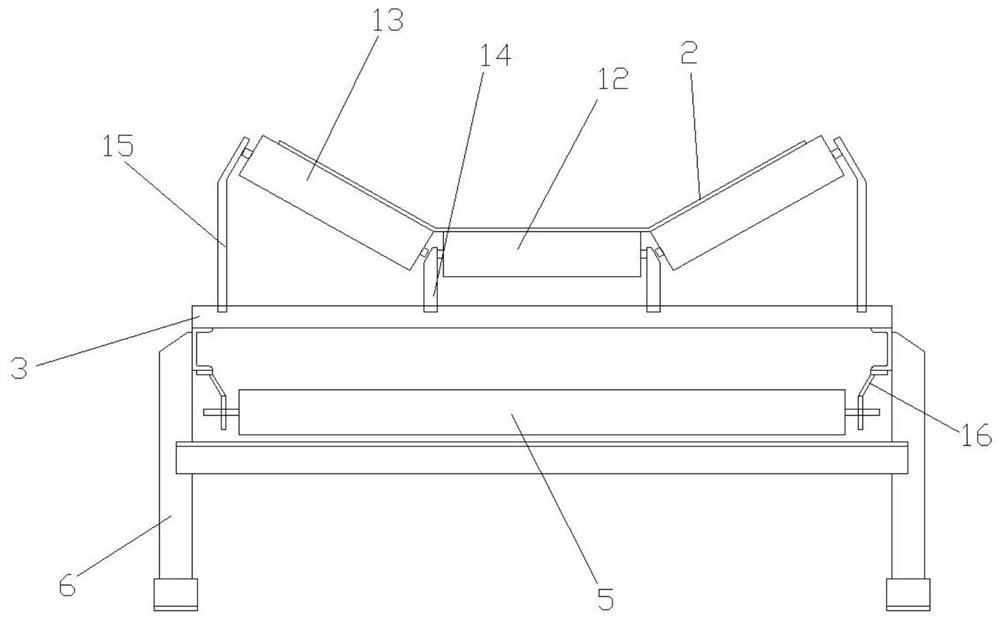

[0075] S1. Add drug a to the oily sand after preliminary sorting, stir until it becomes a paste, and obtain the material to be treated, which falls on the conveyor belt 2 through the feed hopper a1 of the compound feeder 20 The lower end is transported to the higher end and falls into the transfer hopper 8, and the material to be processed dropped by the transfer hopper 8 enters the main body of the conveyor 10 through the collecting hopper 9, and is pushed by the shaftless helical blade 17 through the discharge hopper. Port a19 enters the ball mill 35 through the entrance of the ball mill 35, and ball mills for 10 min at a temperature of 20° C. to 30° C. to obtain a pasty raw material; sodium) and water are mixed; the addition of the medicament a is to add 10 parts of alkaline detergent and 15000 parts of water in the oil and sand...

Embodiment 3

[0082] The system of the deoiling of the harmless oily mud sand of the present embodiment is the same as that of Example 1, and the method of the deoiling of the harmless oily mud sand of the present embodiment is:

[0083] S1. Add drug a to the oily sand after preliminary sorting, stir until it becomes a paste, and obtain the material to be treated, which falls on the conveyor belt 2 through the feed hopper a1 of the compound feeder 20 The lower end is transported to the higher end and falls into the transfer hopper 8, and the material to be processed dropped by the transfer hopper 8 enters the main body of the conveyor 10 through the collecting hopper 9, and is pushed by the shaftless helical blade 17 through the discharge hopper. Port a19 enters the ball mill 35 through the entrance of the ball mill 35, and ball mills for 20 min at a temperature of 20° C. to 30° C. to obtain a pasty raw material; Sodium) and water are mixed; The addition of described medicament a is to add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com