a foam concrete

A foamed concrete and coagulant technology, applied in the field of foamed concrete, can solve the problems of slow solidification, low early strength of foamed concrete, etc., and achieve the effects of reducing the diameter of the foam, the strength is not easy to crack, and the anti-seepage performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

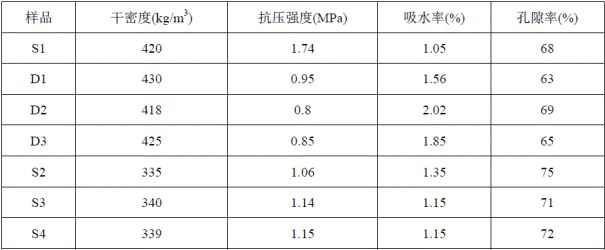

Embodiment 1

[0022]The fatty alcohol polyoxyethylene ether, sodium laurylbenzenesulfonate and tapioca starch are formulated into a composite blowing agent according to the mass ratio of 1:2:2;

[0023] SILRES Powder D silane waterproofing agent and potassium aluminum sulfate dodecahydrate are formulated as waterproofing agents according to the mass ratio of 0.5:1;

[0024] Foam concrete is prepared according to the following preparation method:

[0025] (1) 42.5 strength ordinary Portland cement 50 parts by weight, 42.5 strength aluminum salt cement 5 parts by weight, PCA-I polycarboxylic acid superplasticizer (Subot) 0.6 parts by weight, waterproof agent 0.5 parts by weight, add water to mix uniformly to obtain cement slurry;

[0026] (2) Composite blowing agent 5 by weight added to the residual water in the foam machine foaming, add the cement slurry in step (1) to mix evenly to obtain the foam cement slurry, and then add the foam cement slurry volume 10% density of 600kg / m 3 0.6 parts by ...

Embodiment 2

[0031] The fatty alcohol polyoxyethylene ether, sodium laurylbenzenesulfonate and tapioca starch are formulated into a composite blowing agent according to the mass ratio of 1:1:1;

[0032] SILRES Powder D silane waterproofing agent and potassium aluminum sulfate dodecahydrate are formulated as waterproofing agents according to the mass ratio of 0.5:1;

[0033] Foam concrete is prepared according to the following preparation method:

[0034](1) 42.5 strength ordinary Portland cement 25 parts by weight, 42.5 strength aluminate cement 5 parts by weight, PCA-I polycarboxylic acid superplasticizer (Subot) 0.5 parts by weight, waterproof agent 0.5 parts by weight, add water to mix uniformly to obtain cement slurry;

[0035] (2) Compound blowing agent 3 by weight added to the residual water in the foam machine foaming, add the cement slurry in step (1) to mix evenly to obtain the foam cement slurry, and then add the foam cement slurry volume of 15% density of 300kg / m 3 Ceramic particl...

Embodiment 3

[0038] The fatty alcohol polyoxyethylene ether, sodium laurylbenzenesulfonate and tapioca starch are formulated into a composite blowing agent according to the mass ratio of 1:0.5:2;

[0039] SILRES Powder D silane waterproofing agent and potassium aluminum sulfate dodecahydrate are formulated as waterproofing agents according to the mass ratio of 0.5:1;

[0040] Foam concrete is prepared according to the following preparation method:

[0041] (1) 42.5 strength ordinary Portland cement 45 parts by weight, 42.5 strength aluminate cement 6 parts by weight, PCA-I polycarboxylic acid superplasticizer (Subot) 0.6 parts by weight, waterproof agent 0.6 parts by weight, add water to mix uniformly to obtain cement slurry;

[0042] (2) Composite blowing agent 1 by weight added to the spare amount of water in the foam machine foaming, add the cement slurry in step (1) to mix evenly to obtain foam cement slurry, and then add foam cement slurry volume 5% density of 300kg / m 3 The ceramic part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com