A kind of polymethylene polyphenyl polyisocyanate composition and preparation method thereof

A technology of polymethylene polyphenyl and polyisocyanate, which is applied in the field of preparing polymethylene polyphenyl polyisocyanate, and can solve problems such as difficult operation, high operation and equipment costs, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Take 100g of N,N-dimethylformamide, add 100g of polyimide, mix and dissolve completely, add 3g of SiC and 0.3g of Pd nanoparticles to the polyimide solution to obtain a mixed solution, and then rotate the mixed solution by rotating The coating instrument is evenly coated on the treated ceramic substrate. The ceramic substrate should be polished and solvent cleaned before use, and dried for use. Then place the ceramic substrate in the oven, set a gradient heating program, start from room temperature, first heat up to 80 °C for 1 hour, and then program the temperature to 300 °C after 200 minutes, and keep the temperature for 2 hours, and then the ceramic substrate is finished. Place in boiling water to remove the membrane.

[0079] The obtained polyimide composite carbon film was trimmed neatly and placed in two stacked quartz sheets, and then placed in a vacuum tube sintering furnace, and nitrogen gas was introduced into the vacuum tube sintering furnace, and the nitroge...

Embodiment 2

[0081] Take 100g of N,N-dimethylformamide, add 100g of polyimide to completely mix and dissolve, add 2g of SiC and 0.1g of Pd nanoparticles to the polyimide solution to obtain a mixed solution, and then rotate the mixed solution by rotating The coating instrument is evenly coated on the treated ceramic substrate. The ceramic substrate should be polished and solvent cleaned before use, and dried for use. Then place the ceramic substrate in the oven, set the gradient heating program, start from room temperature, first heat up to 60 °C for 2 hours, and then program the temperature to 250 °C after 150 minutes, and keep the temperature for 3 hours, and then heat the ceramic substrate after the end. Place in boiling water to remove the membrane.

[0082] The obtained polyimide composite carbon film was trimmed neatly and placed in two stacked quartz sheets, and then placed in a vacuum tube sintering furnace, and nitrogen gas was introduced into the vacuum tube sintering furnace, and...

Embodiment 3

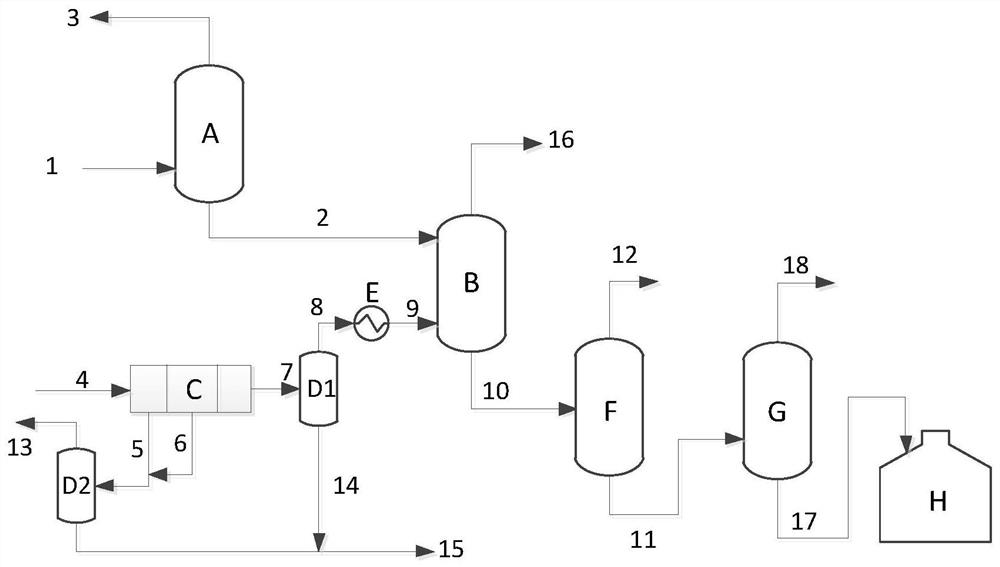

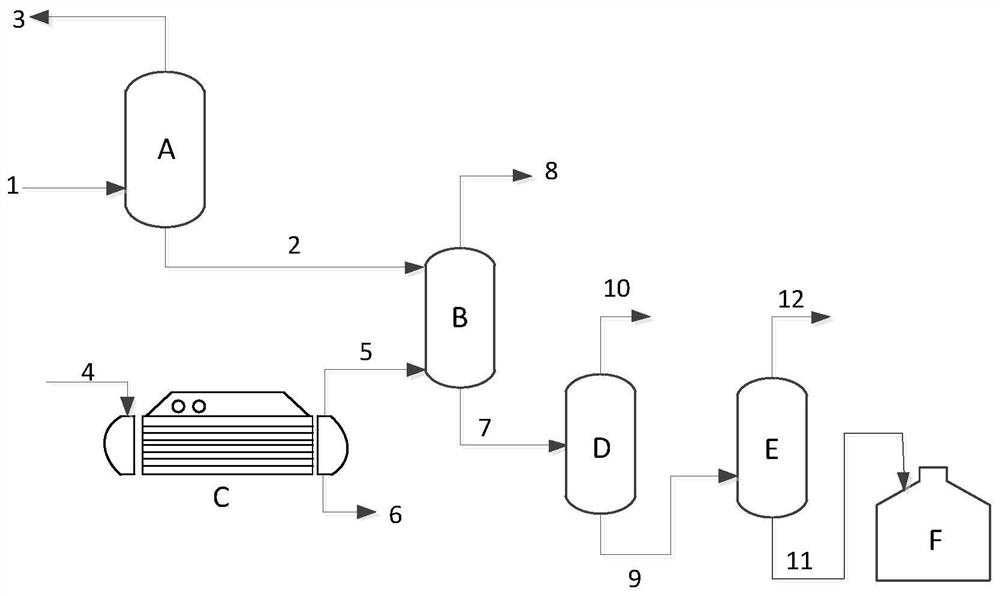

[0087] use figure 1 As shown in the process flow, the prepared reaction solution is passed to the bottom of the dephosgenation tower A, and heat treated under normal pressure and 140 ° C for 1 h, and the phosgene content in the treated reaction solution 2 is reduced to below 100ppm . Then the dephosgenated reaction solution 2 is sent to the top of the HCl stripper B. The top gas stream 3 of the dephosgenation tower A mainly contains phosgene, HCl and solvent.

[0088] The HCl gas flow 4 containing 10,000 ppm of the material that affects the phosgene adduct content is sent to the membrane separation device C, and the HCl gas flow pressure is 3 bar (gauge pressure), and the selected membrane separation unit contains 3 separation blocks, which are prepared in Example 1. Polyimide composite carbon membrane, after 3-stage membrane separation, the purified HCl gas flow 7 enters the gas-liquid separation tank D1, and the gas phase 8 above the gas-liquid separation tank D1 enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com