Polyamine-polyphenol modified graphene oxide carrier, and preparation method and application thereof

A polyphenol oxidation, graphene technology, applied in biochemical equipment and methods, chemical instruments and methods, immobilized on or in inorganic carriers, etc., can solve problems such as poor stability and reusability of immobilized enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of dopamine-polyethyleneimine co-modified graphene oxide (GO) as a carrier of adenylyl cyclase (AC) cross-linked enzyme polymer

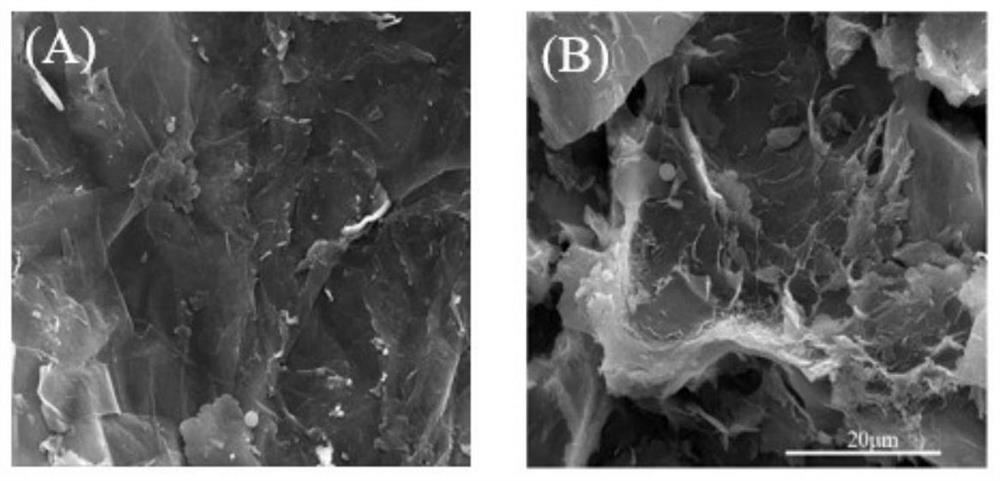

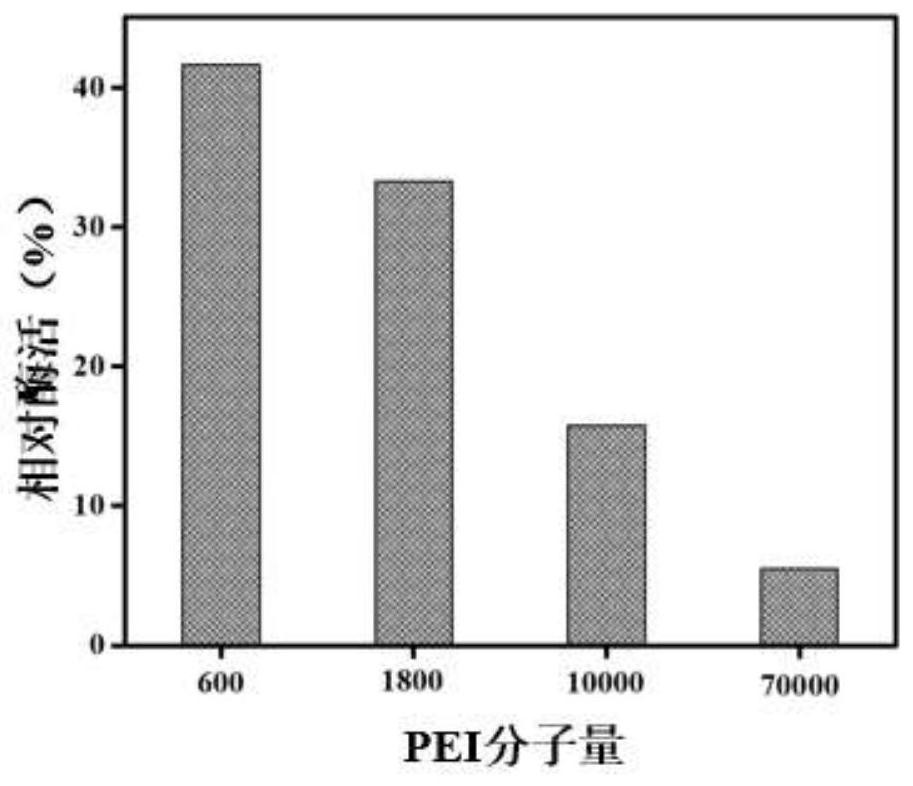

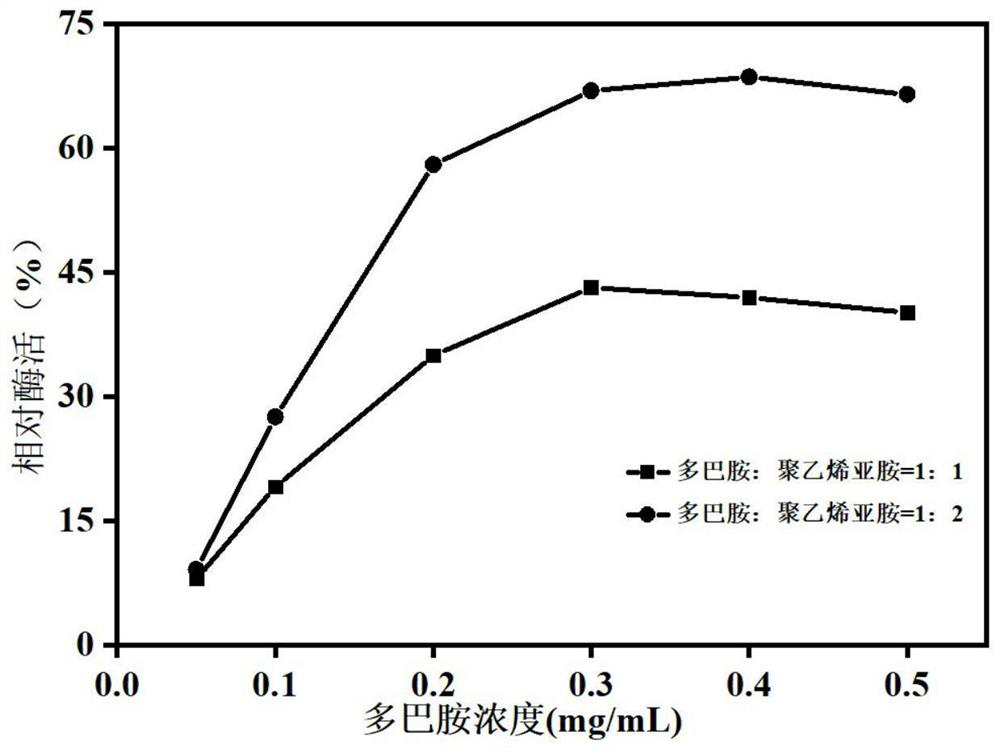

[0039] 1. Preparation of dopamine-polyethyleneimine co-modified GO

[0040] Dissolve 100 mg of GO in 100 ml of Tris-HCL buffer (pH 8.5), and disperse it uniformly by ultrasound to prepare a 1 mg / mL GO dispersion. Prepare a 2 mg / ml PEI solution with Tris-HCL buffer, add 50 mg of DA into the PEI solution, and adjust the volume to 50 ml with a volumetric flask to obtain a DA / PEI mixed solution. Take 5ml graphene oxide dispersion (1mg / mL), add 2ml Tris-HCL buffer solution and 3ml DA / PEI mixed solution. The final system is 10ml, the concentration of dopamine is 0.3mg / ml, and DA:PEI=1:2. The mixture was reacted in a shaker at 25° C. for 16 h, and then centrifuged, washed and dried to obtain the modified carrier GO-PEI / PDA. Take the same amount of graphene oxide and GO-PEI / PDA solids and grind them into powder. According to...

Embodiment 2

[0057] Example 2: Dopamine-polylysine co-modified GO as carrier to prepare AC cross-linked enzyme polymer

[0058] Use Tris-HCL buffer solution with a pH of 8.5 to prepare a 5 mg / mL polylysine (EPL) solution, dissolve DA in the EPL solution so that the ratio of DA to EPL in the solution is 1:1, take 5 mL of the mixed solution and add 5ml of graphene oxide dispersion (20mg / mL) was reacted in a shaker at 30°C for 24h, then centrifuged, washed, and dried to obtain dopamine-polylysine co-modified GO.

[0059] The prepared dopamine-polylysine co-modified GO was processed according to the preparation method of the cross-linked enzyme polymer in Example 1, and finally the AC cross-linked enzyme polymer immobilized on the dopamine-polylysine graphene oxide was obtained. body.

[0060] Referring to the adenylyl cyclase enzyme activity assay method in Example 1 above, the assay results show that the relative enzyme activity of the cross-linked enzyme polymer with dopamine-polylysine co...

Embodiment 3

[0063] Example 3: Tannic acid-polyetheramine co-modified GO as carrier to prepare AC cross-linked enzyme polymer

[0064] Use Tris-HCL buffer (pH7.5) to prepare 2 mg / mL polyetheramine solution, dissolve tannic acid in the polyetheramine solution, so that the ratio of tannic acid and polyetheramine in the solution is 1:1, Take 5mL of the mixed solution and add 5ml of graphene oxide dispersion (1mg / mL), react in a shaker at 10°C for 16h, then centrifuge, wash, and dry to finally obtain tannic acid-polyetheramine co-modified graphene oxide .

[0065] Referring to the above method, tannic acid and polyetheramine were added separately to the system to prepare GO modified with tannic acid and GO modified with polyetheramine, respectively.

[0066] 1 mL of tris(carboxymethyl)ethylenediamine solution with a concentration of 100 mM and 1 mL of NiCl with a concentration of 100 mM 2 React for 1h, then react with 5mL AC enzyme solution for 1h, the protein concentration in the AC enzyme ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com