Polycaprolactone/methylacryloyl elastin nanofiber composite membrane and preparation method and application thereof

A technology of methacrylylating elasticity and polycaprolactone, which is applied in the field of medical materials for tendon injury repair, can solve the problems that biological materials cannot meet clinical requirements, and achieve tissue engineering repair, avoid cytotoxicity, and be easy to batch the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

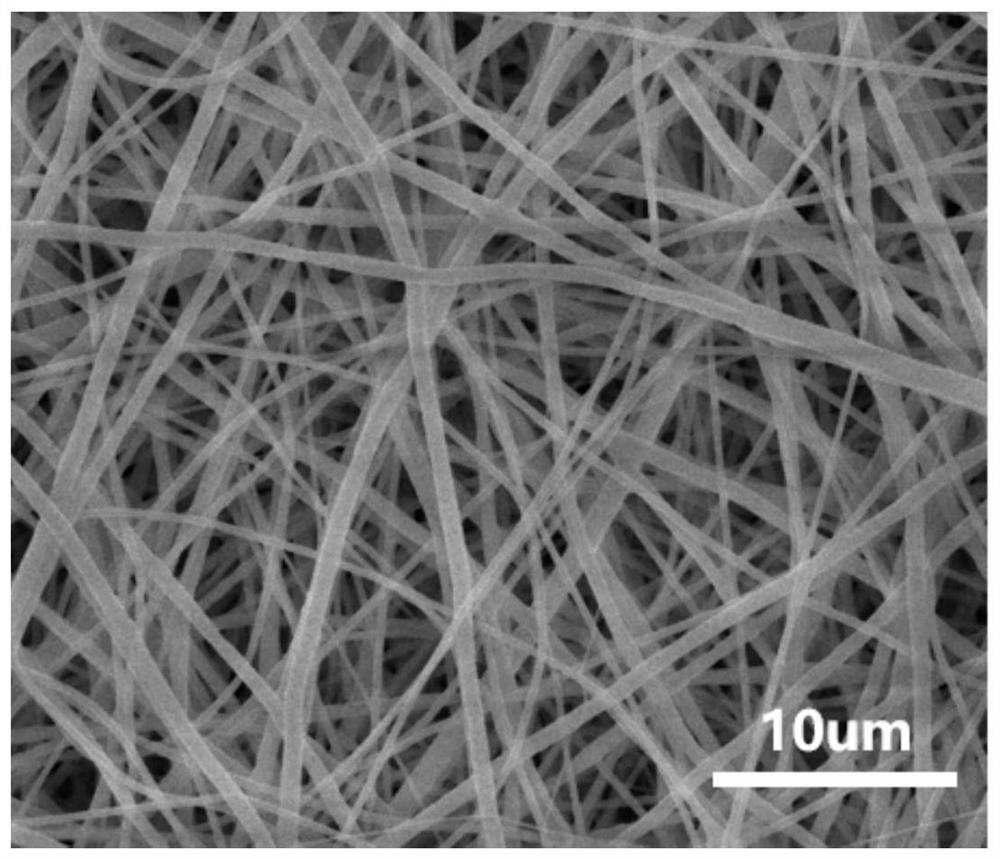

[0036] A preparation method of polycaprolactone / methacryloyl elastin nanofiber composite film includes the following steps:

[0037] (1) Weigh 10g of soluble elastin and add it to 100mL of PBS solution, stir under a constant temperature water bath at 50℃ until the elastin is completely dissolved; add 20ml of methacrylic anhydride to 10w through a syringe pump at a rate of 0.5ml / min / v% elastin solution, and then placed at 50°C and stirred for 3h; then add 400mL of 50°C PBS solution to dilute the reaction solution of elastin and methacrylic anhydride, stir for 30min and terminate the reaction; add the diluted solution Put it into a dialysis bag with MW=1000 and dialyzed in deionized water at 40°C for 12 days. During this period, the fluid was changed every 8h to remove unreacted methacrylic anhydride and by-products; after 12 days, take it out and pass the dialyzed solution through Filter on qualitative filter paper and collect the filtrate; pre-freeze the collected filtrate and f...

Embodiment 2

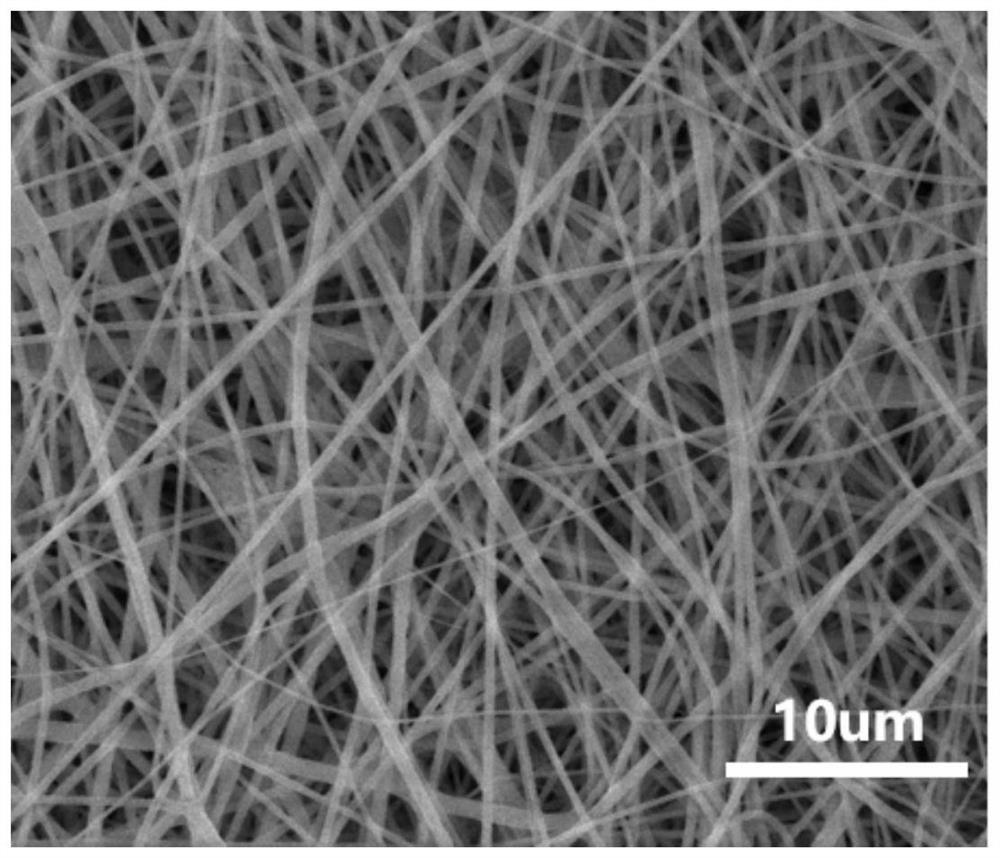

[0041] A preparation method of polycaprolactone / methacryloyl elastin nanofiber composite film includes the following steps:

[0042] (1) Weigh 10g of soluble elastin and add it to 100mL of PBS solution, stir under a constant temperature water bath at 50℃ until the elastin is completely dissolved; add 20ml of methacrylic anhydride to 10w through a syringe pump at a rate of 0.5ml / min / v% elastin solution, and then placed at 50°C and stirred for 3h; then add 400mL of 50°C PBS solution to dilute the reaction solution of elastin and methacrylic anhydride, stir for 30min and terminate the reaction; add the diluted solution Put it into a dialysis bag with MW=1000 and dialyzed in deionized water at 40°C for 12 days. During this period, the fluid was changed every 8h to remove unreacted methacrylic anhydride and by-products; after 12 days, take it out and pass the dialyzed solution through Filter on qualitative filter paper and collect the filtrate; pre-freeze the collected filtrate and f...

Embodiment 3

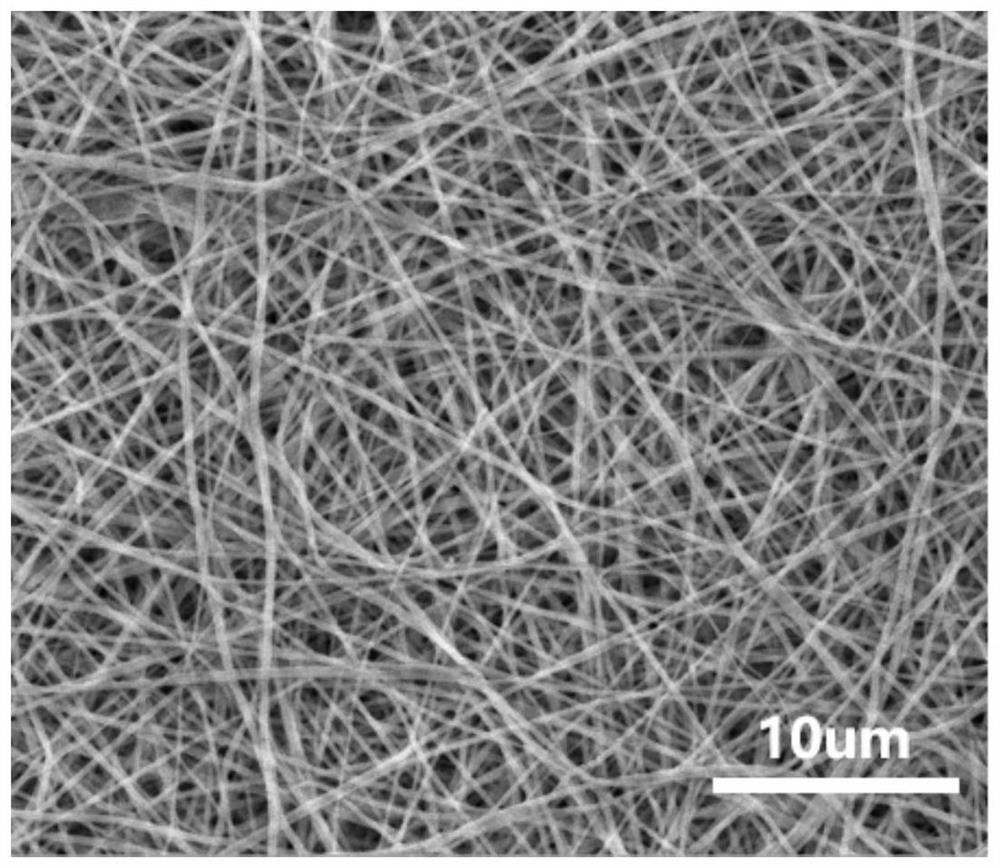

[0046] A preparation method of polycaprolactone / methacryloyl elastin nanofiber composite film includes the following steps:

[0047] (1) Weigh 10g of soluble elastin and add it to 100mL of PBS solution, stir under a constant temperature water bath at 50℃ until the elastin is completely dissolved; add 20ml of methacrylic anhydride to 10w through a syringe pump at a rate of 0.5ml / min / v% elastin solution, and then placed at 50°C and stirred for 3h; then add 400mL of 50°C PBS solution to dilute the reaction solution of elastin and methacrylic anhydride, stir for 30min and terminate the reaction; add the diluted solution Put it into a dialysis bag with MW=1000 and dialyzed in deionized water at 40°C for 12 days. During this period, the fluid was changed every 8h to remove unreacted methacrylic anhydride and by-products; after 12 days, take it out and pass the dialyzed solution through Filter on qualitative filter paper and collect the filtrate; pre-freeze the collected filtrate and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com