A three-dimensional porous structure nickel-modified hy molecular sieve oxygen carrier and its preparation and application

A three-dimensional, porous structure technology, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, bulk chemical production, etc., can solve the problems of complex liquid phase product components, complex refining process, difficult large-scale application, etc., to achieve good metal Particle dispersibility and catalytic effect, simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Oxygen carrier preparation:

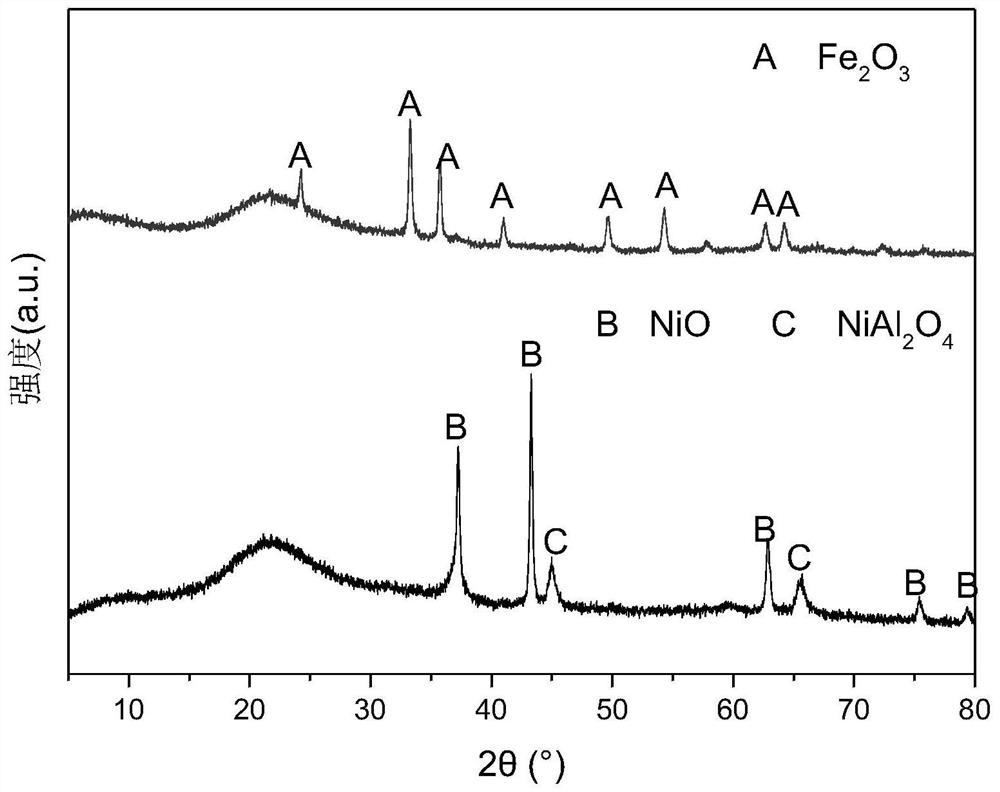

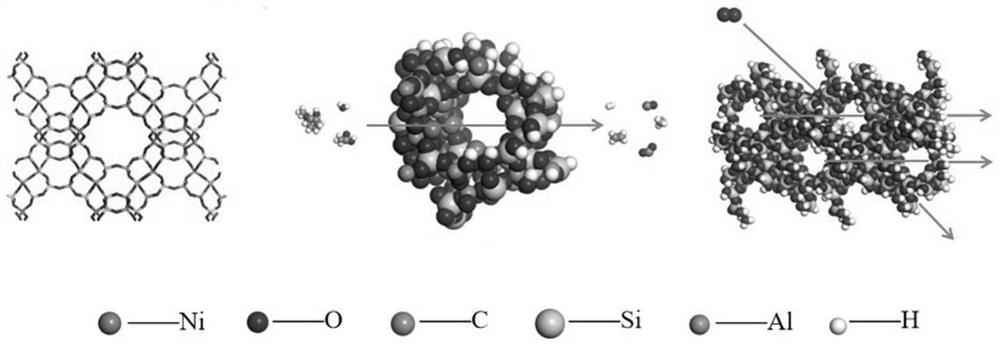

[0048] Take 29.081g Ni(NO 3 ) 2 ·6H 2O, 52.821g NaY molecular sieve (silicon to aluminum ratio is 4.8) and 106.89g NH 4 Dissolve Cl in 1L of distilled water, stir the mixture in the beaker with a magnetic stirrer at a speed of 550r / min at room temperature for 2 hours, then slowly drop 1mol / L ammonium carbonate solution into the solution with a rubber dropper until the solution pH = 3.4, continue to stir until the solution becomes a colloidal suspension. Dry the suspension at 105°C for 12h in a blast drying oven, put the dried solid into a muffle furnace, and calcinate at 400°C for 2h and then at 900°C for 4h in an air atmosphere. After cooling to room temperature, a Ni / HY oxygen carrier is obtained, wherein the mass content of Ni is 10%, and the mass content of HY molecular sieve is 90%.

[0049] Catalyst activity evaluation:

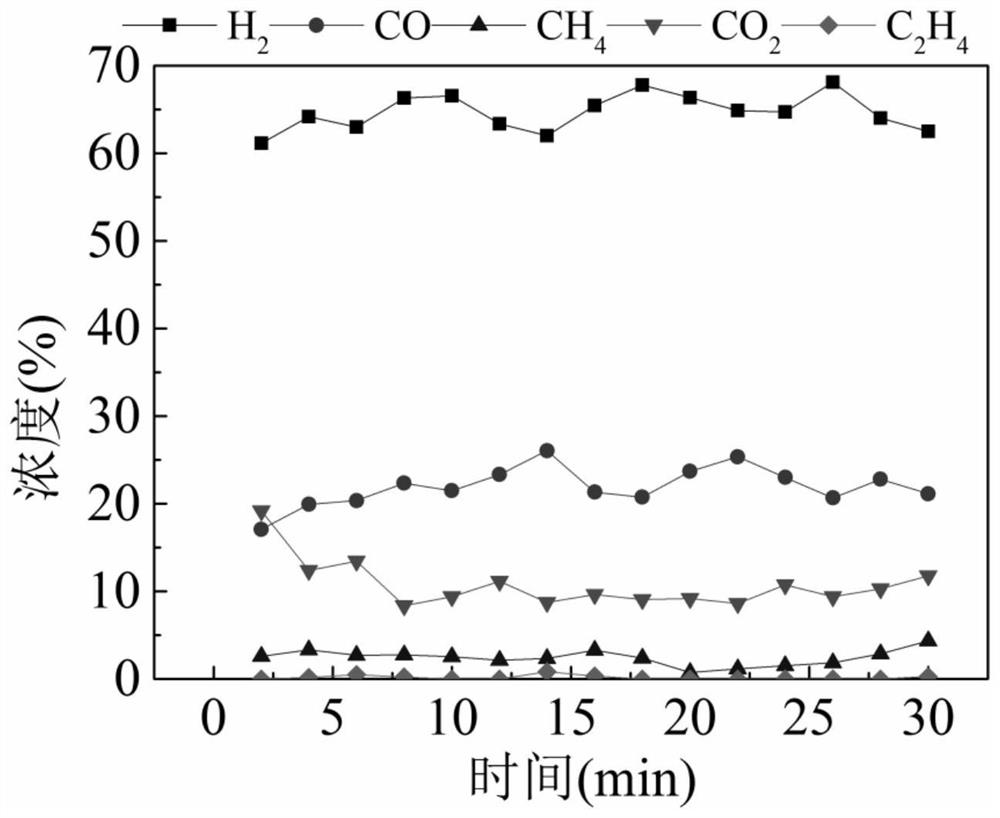

[0050] The chemical chain reformation reaction of wood vinegar is carried out on a small fixed bed device. F...

Embodiment 2

[0054] Oxygen carrier preparation:

[0055] Take 29.081g Ni(NO 3 ) 2 ·6H 2 O, 23.455g NaY molecular sieve (silicon to aluminum ratio is 4.8) and 106.89g NH 4 Dissolve Cl in 1L of distilled water, stir the mixture in the beaker with a magnetic stirrer at a speed of 550r / min at room temperature for 2 hours, then slowly drop 1mol / L ammonium carbonate solution into the solution with a rubber dropper until the solution pH = 3.4, continue to stir until the solution becomes a colloidal suspension. Dry the suspension at 105°C for 12h in a blast drying oven, put the dried solid into a muffle furnace, and calcinate at 400°C for 2h and then at 900°C for 4h in an air atmosphere. After cooling to room temperature, a Ni / HY oxygen carrier was obtained, wherein the mass content of Ni was 20%, and the mass content of HY molecular sieve was 80%.

[0056] Catalyst activity evaluation:

[0057] The chemical chain reformation reaction of wood vinegar is carried out on a small fixed bed devic...

Embodiment 3

[0059] Oxygen carrier preparation:

[0060] Take 29.081g Ni(NO 3 ) 2 ·6H 2 O, 23.455g NaY molecular sieve (silicon to aluminum ratio is 4.8) and 106.89g NH 4 Dissolve Cl in 1L of distilled water, stir the mixture in the beaker with a magnetic stirrer at a speed of 550r / min at room temperature for 2 hours, then slowly drop 1mol / L ammonium carbonate solution into the solution with a rubber dropper until the solution pH = 3.4, continue to stir until the solution becomes a colloidal suspension. Dry the suspension at 105°C for 12h in a blast drying oven, put the dried solid into a muffle furnace, and calcinate at 400°C for 2h and then at 900°C for 4h in an air atmosphere. After cooling to room temperature, a Ni / HY oxygen carrier was obtained, wherein the mass content of Ni was 20%, and the mass content of HY molecular sieve was 80%.

[0061] Catalyst activity evaluation:

[0062] The chemical chain reformation reaction of wood vinegar is carried out on a small fixed bed devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com