Patents

Literature

32results about How to "Strong anti-coking performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

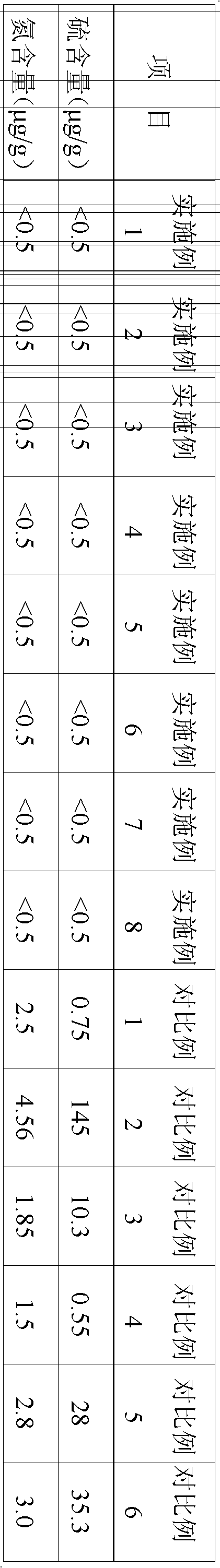

A kind of hydrorefining method of distillate oil

ActiveCN102268283AImprove hydrogenation activityImprove stabilityPhysical/chemical process catalystsHydrocarbon oils treatmentSlurryCobalt

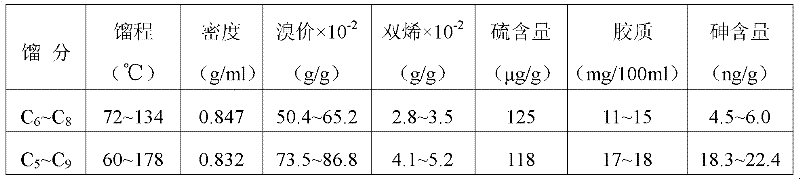

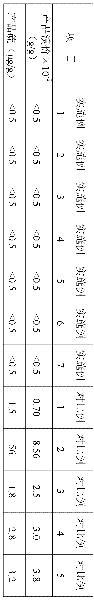

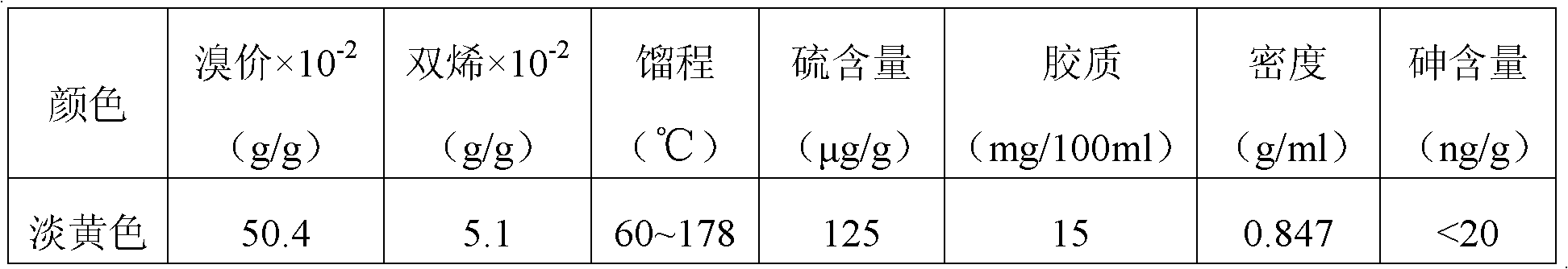

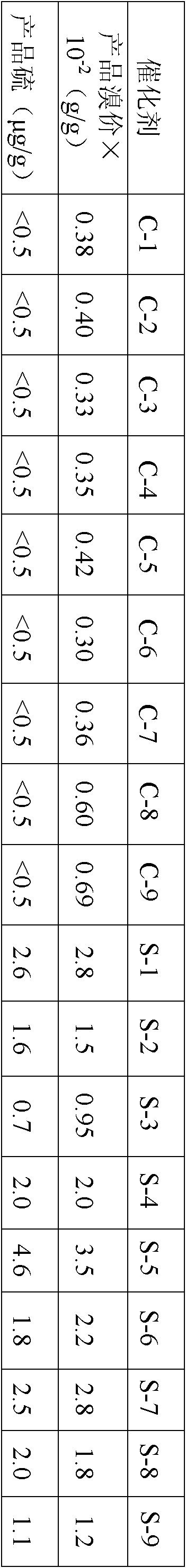

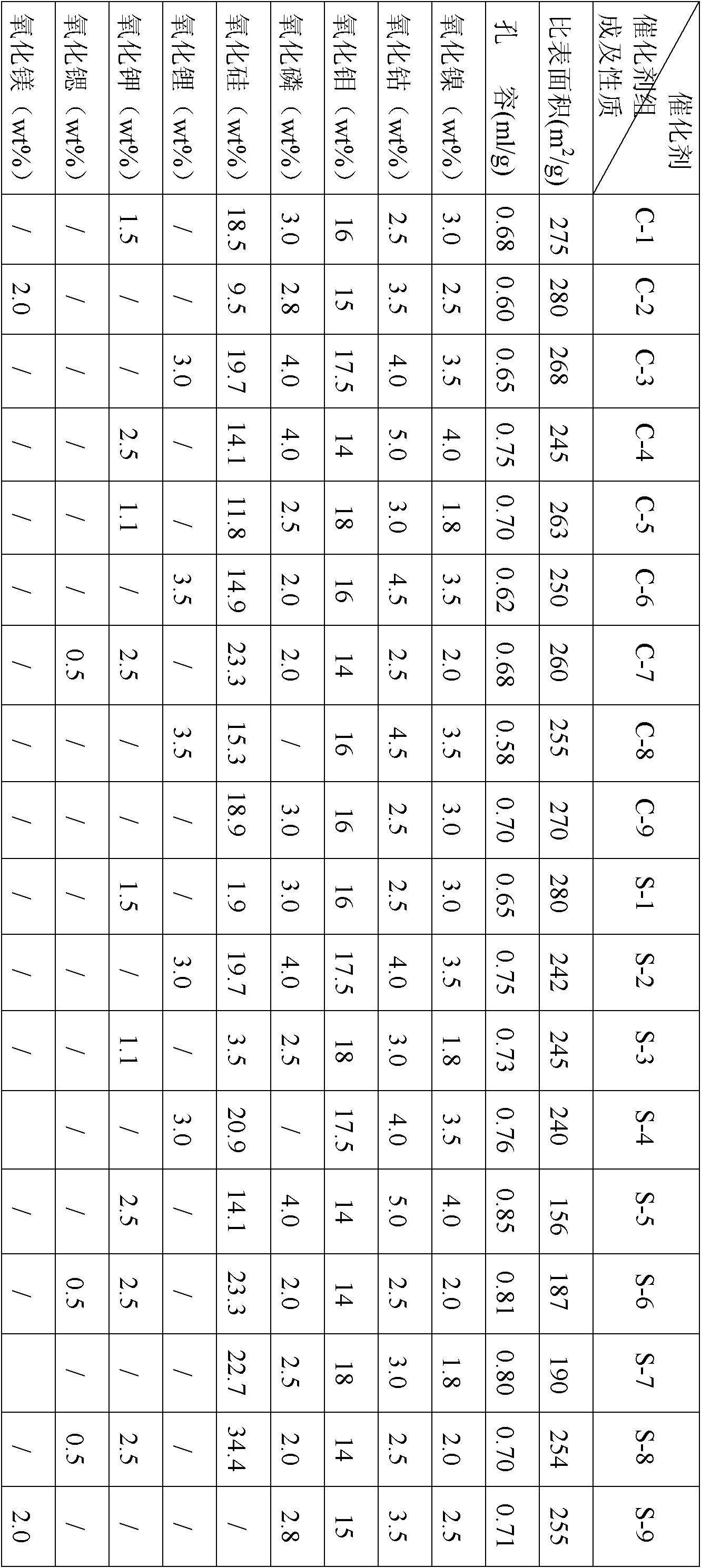

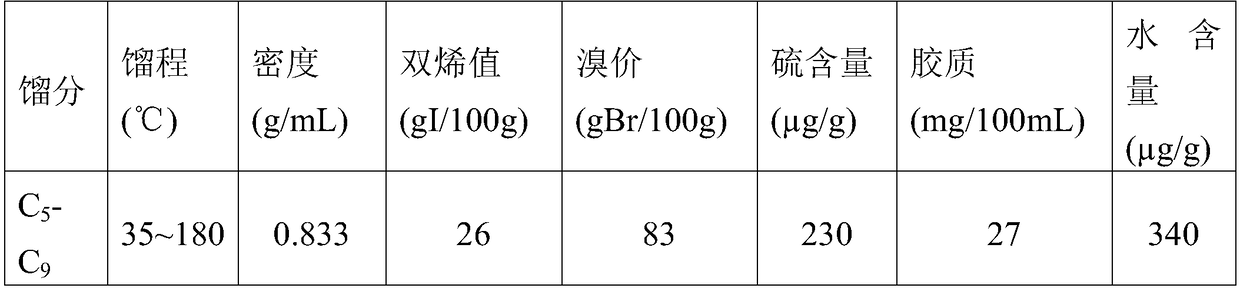

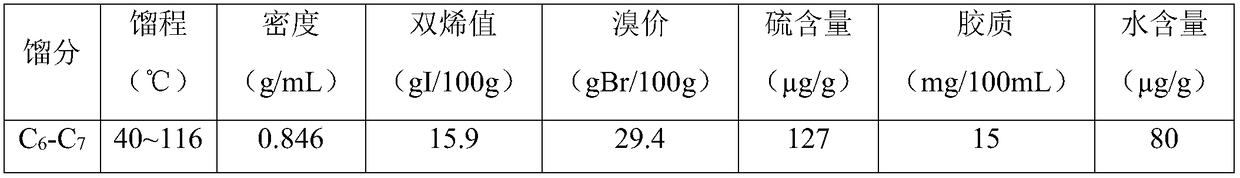

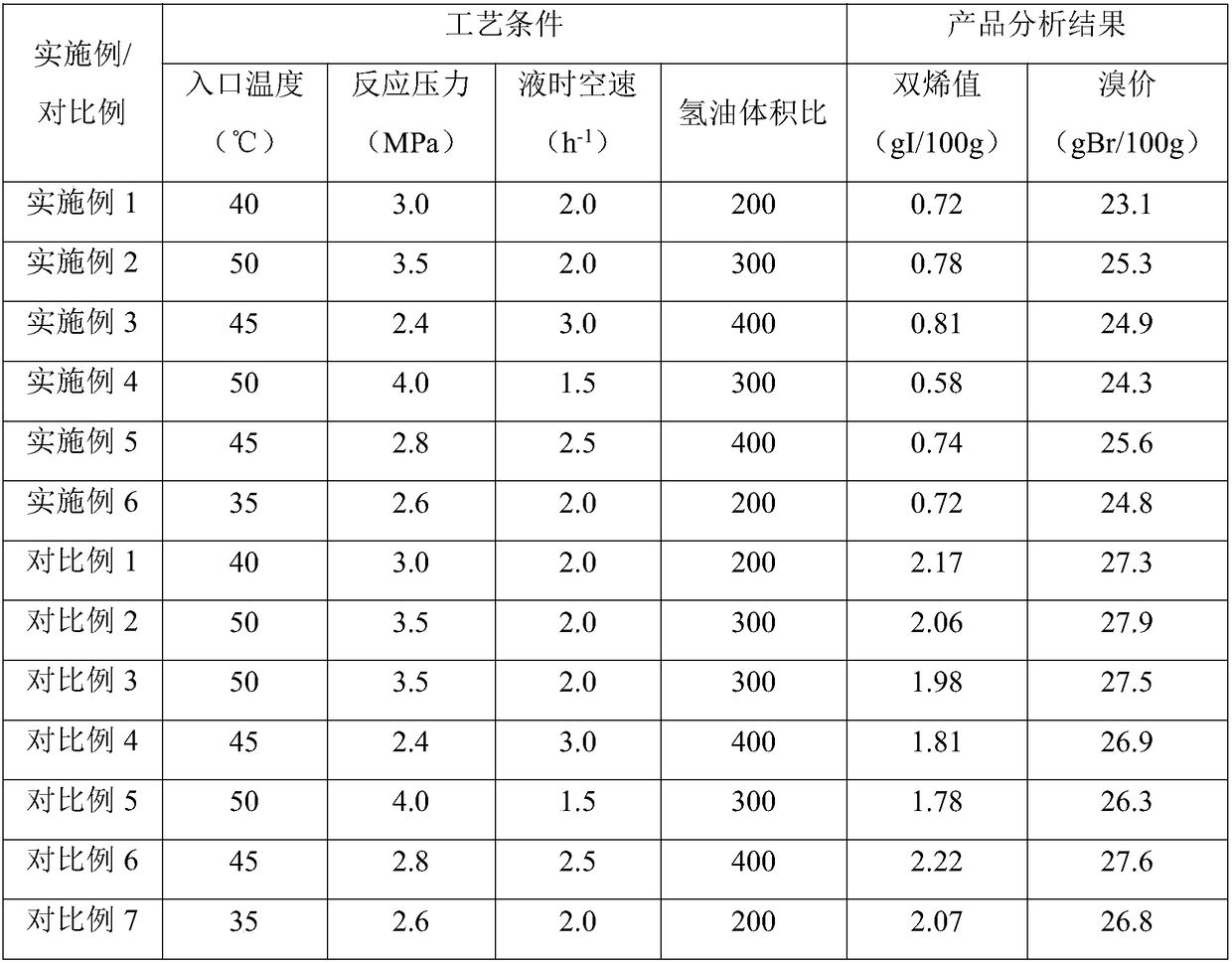

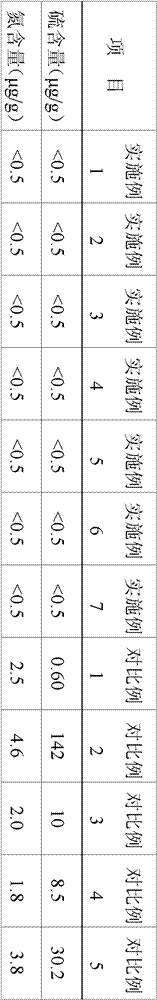

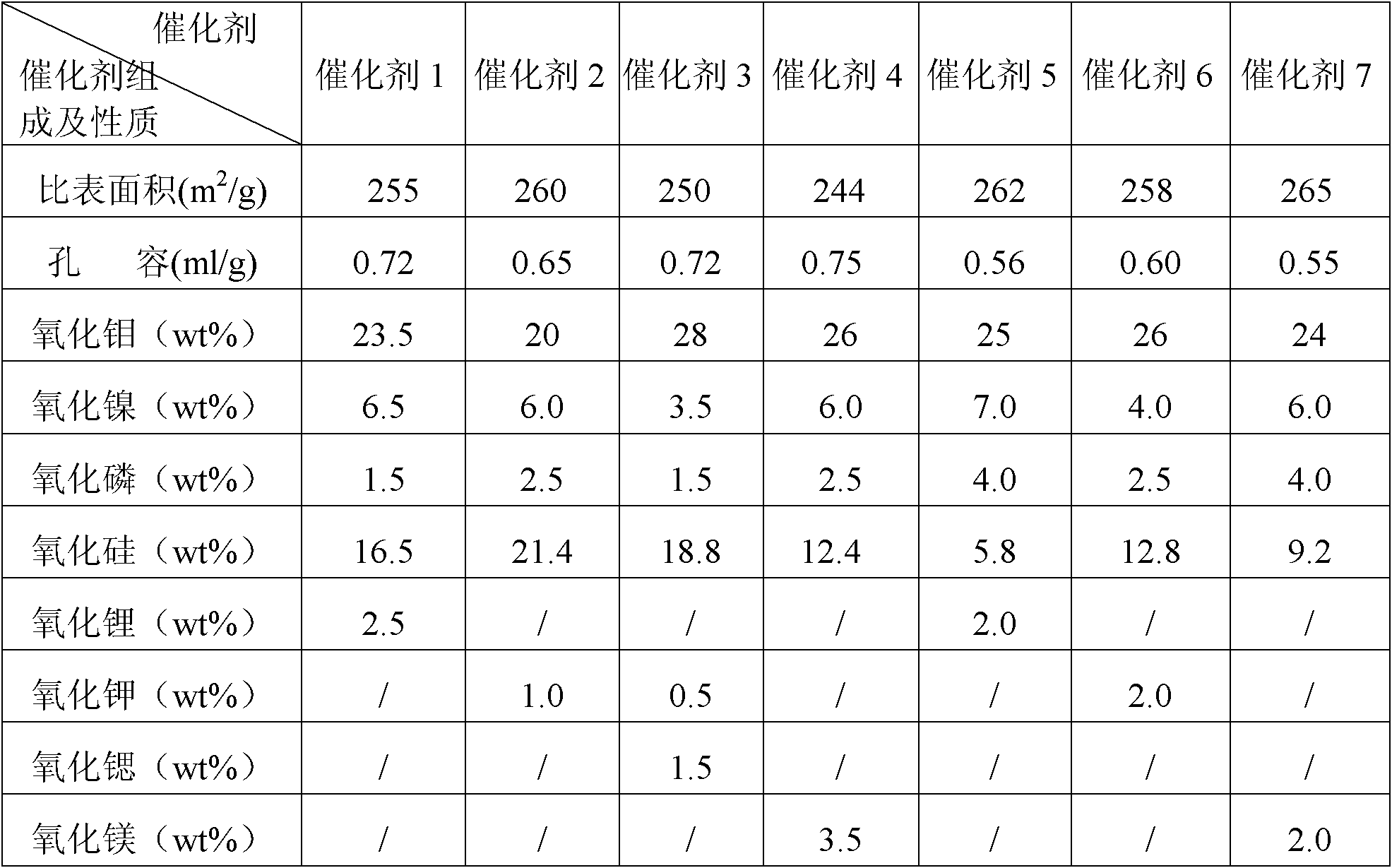

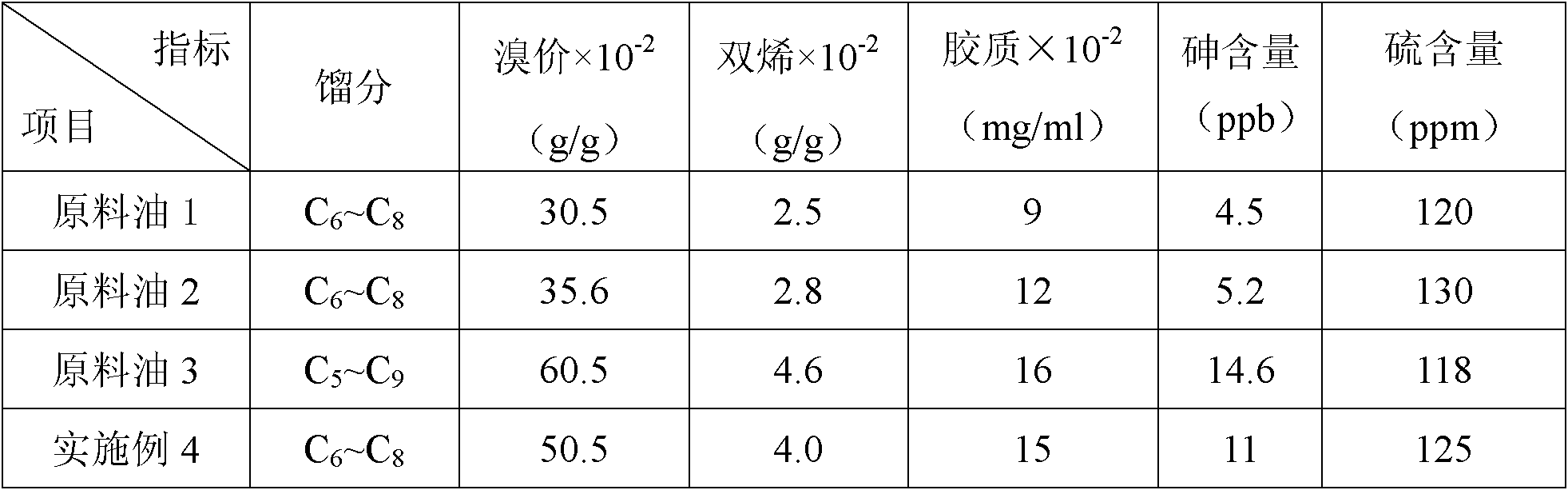

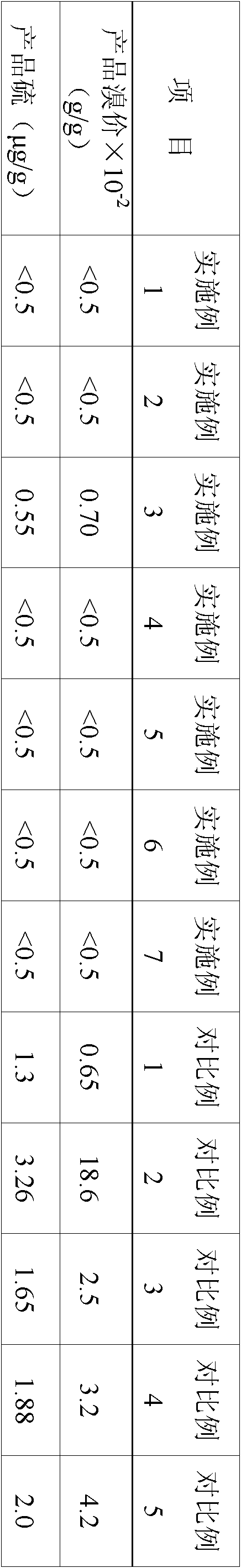

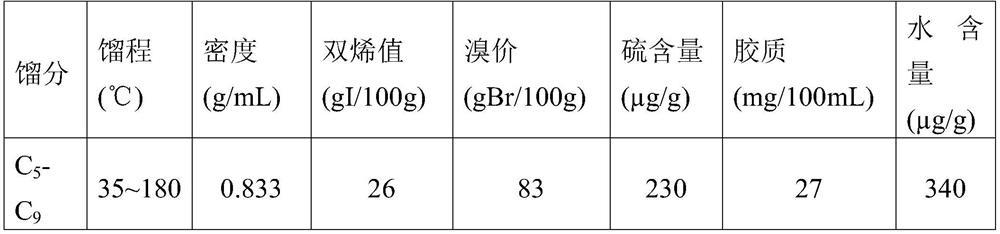

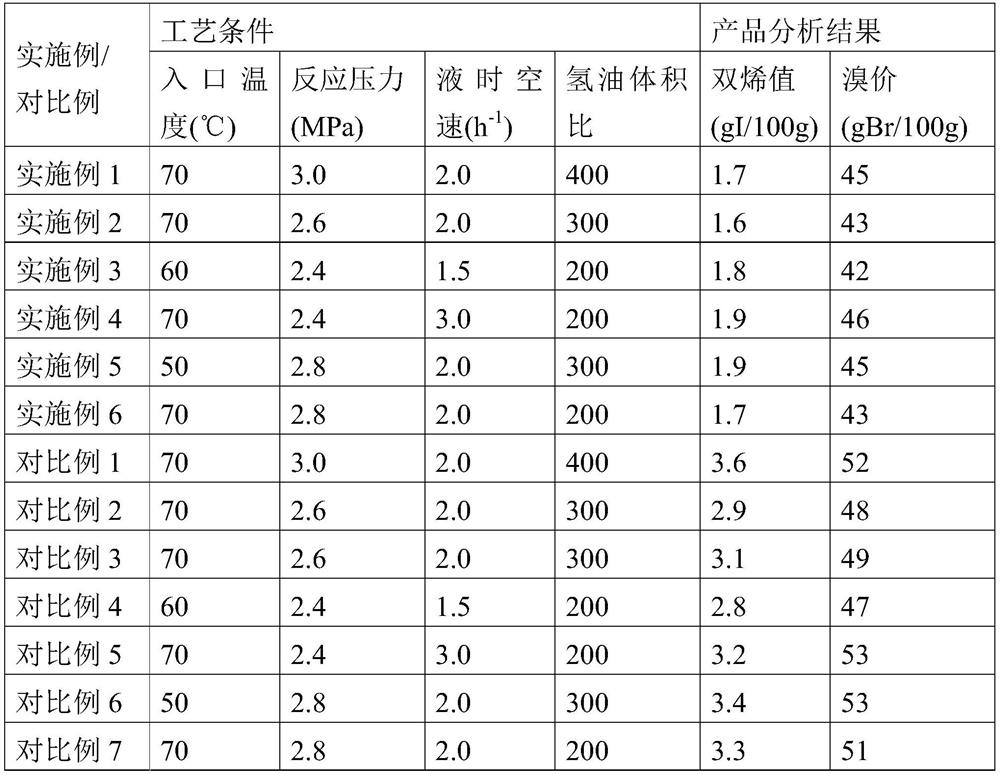

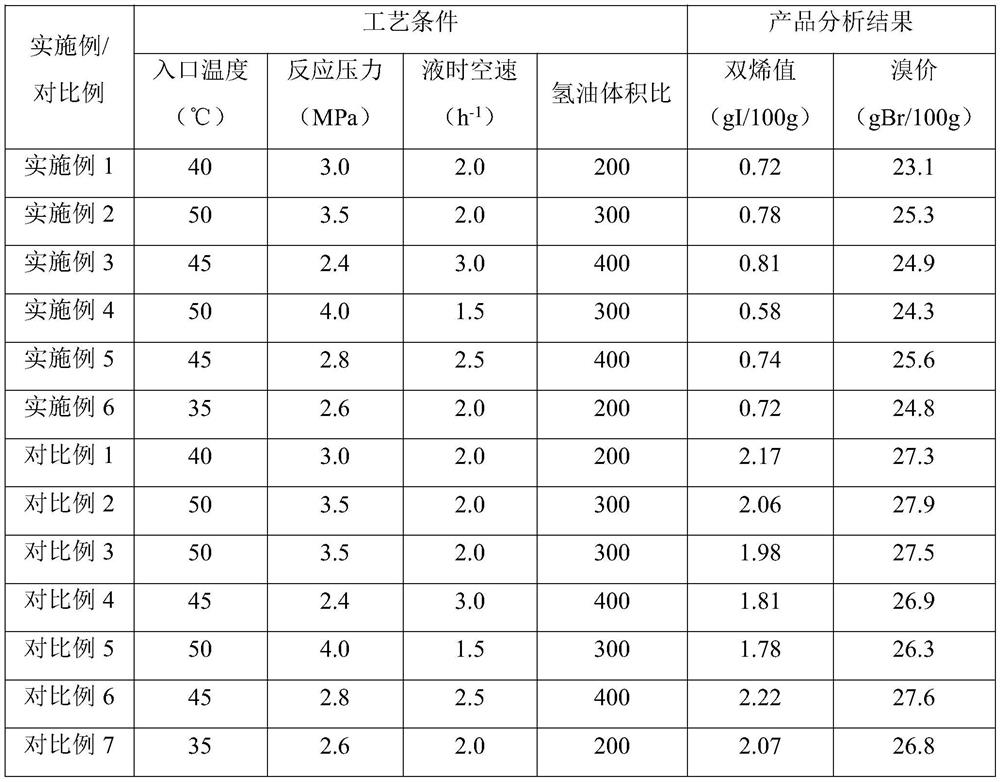

The invention provides a hydrorefining method of distillate oil. In the hydrorefining method, a cobalt molybdenum nickel hydrogenation catalyst is used; hydrogenation process conditions are as follows: the inlet temperature is 200-320 DEG C, the operation pressure is larger than or equal to 2.4MPa, the volume space velocity of a liquid is 1-5h<-1>, and the volume ratio of hydrogen to oil is 100-500; in the cobalt molybdenum nickel hydrogenation catalyst, silicon-containing alumina is used as a carrier, cobalt, molybdenum and nickel are used as active components, and phosphorus and alkali metal are added to be used as auxiliaries; and the precursor of the silicon-containing alumina carrier is pseudo boehmite containing amorphous silica-alumina and is obtained by the steps of firstly preparing an amorphous silica-alumina slurry and a pseudo boehmite slurry, mixing the two slurries, ageing, and then carrying out posttreatment processes such as filtering, washing and drying. According to the invention, hydrorefining is carried out on a first-stage hydrogenation product of full-fraction cracked gasoline by using the hydrorefining method, wherein the bromine value in the hydrogenation product is less than 1.0*10<-2>g / g and the content of sulfur in the hydrogenation product is less than 1.0mu g / g, thereby meeting the second-stage hydrogenation requirements of the cracked gasoline.

Owner:PETROCHINA CO LTD

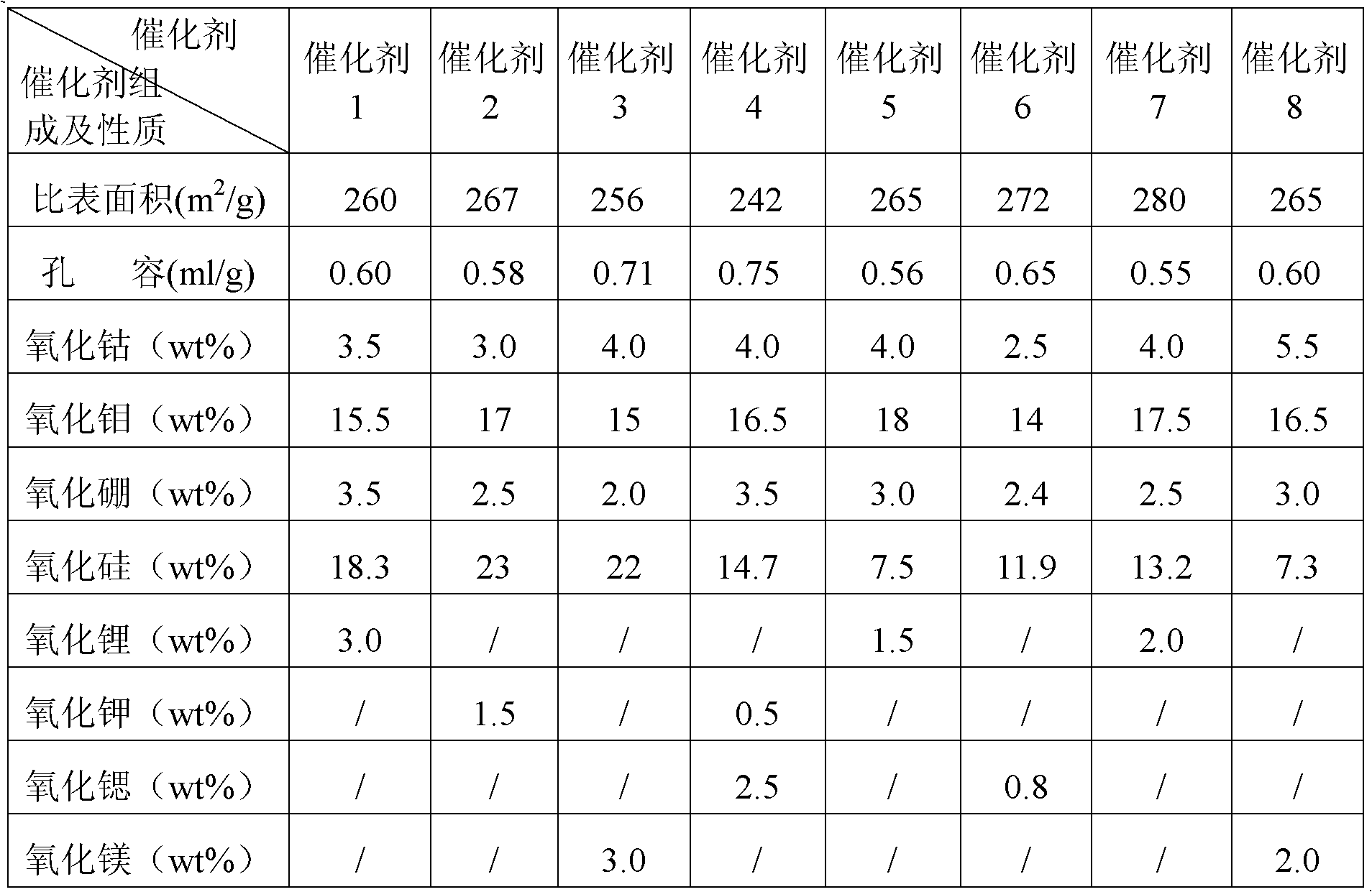

Hydrofining catalyst and preparation method thereof

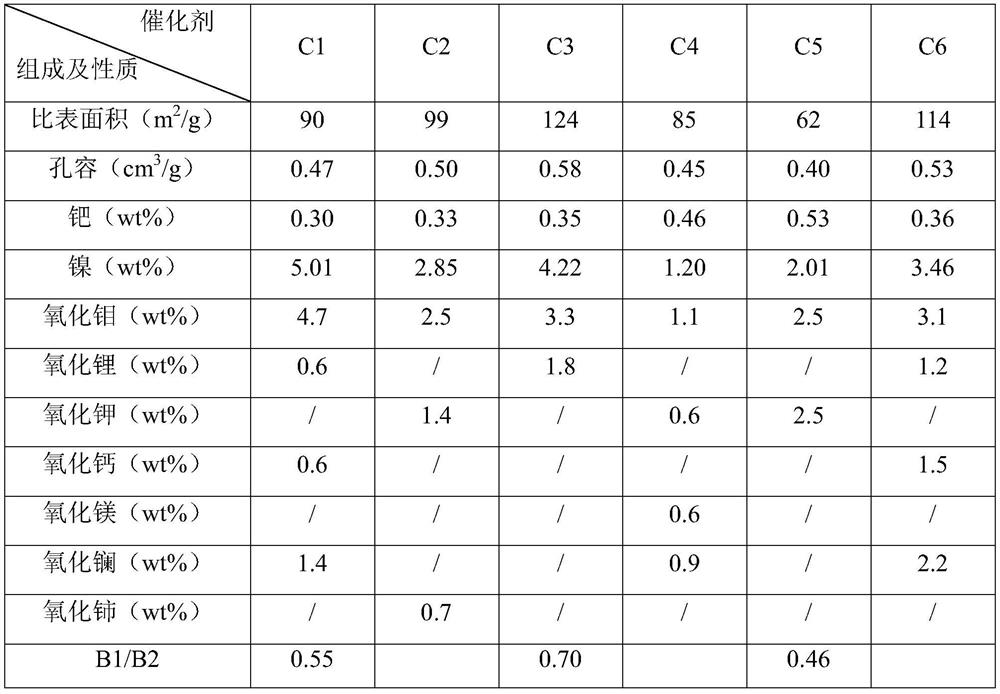

ActiveCN102319579ALarge specific surface areaOvercoming the problem of poor moldingPhysical/chemical process catalystsRefining to eliminate hetero atomsAlkaline earth metalSilicon oxide

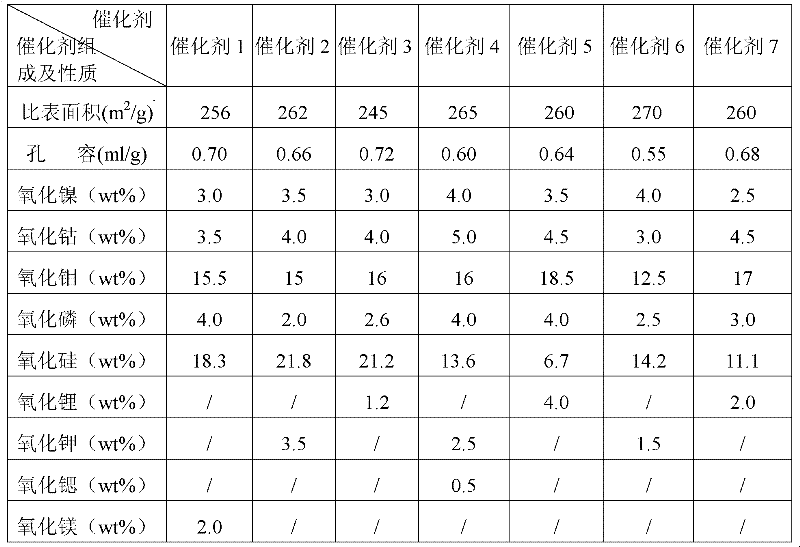

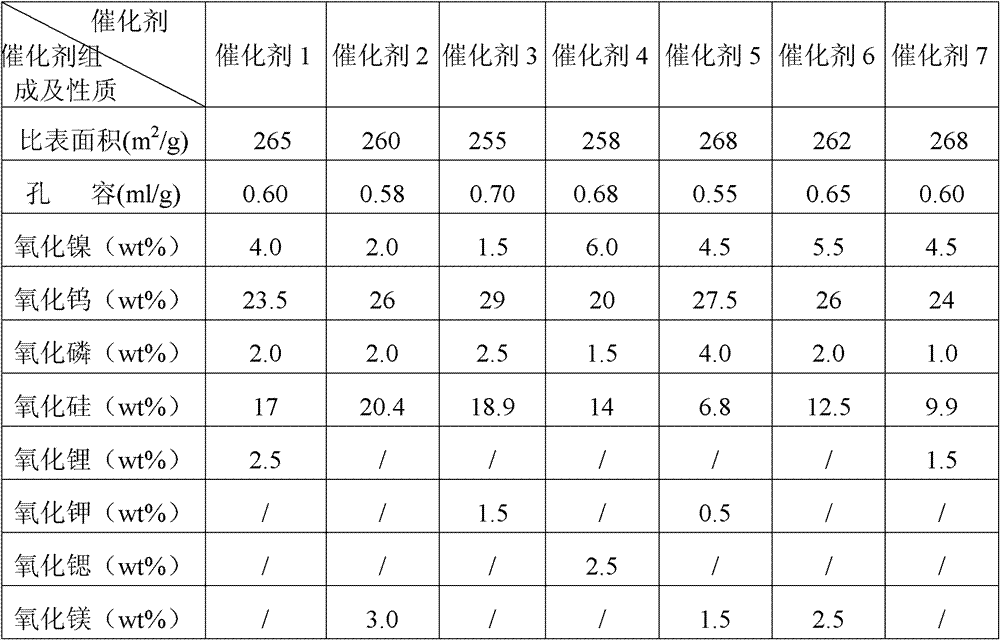

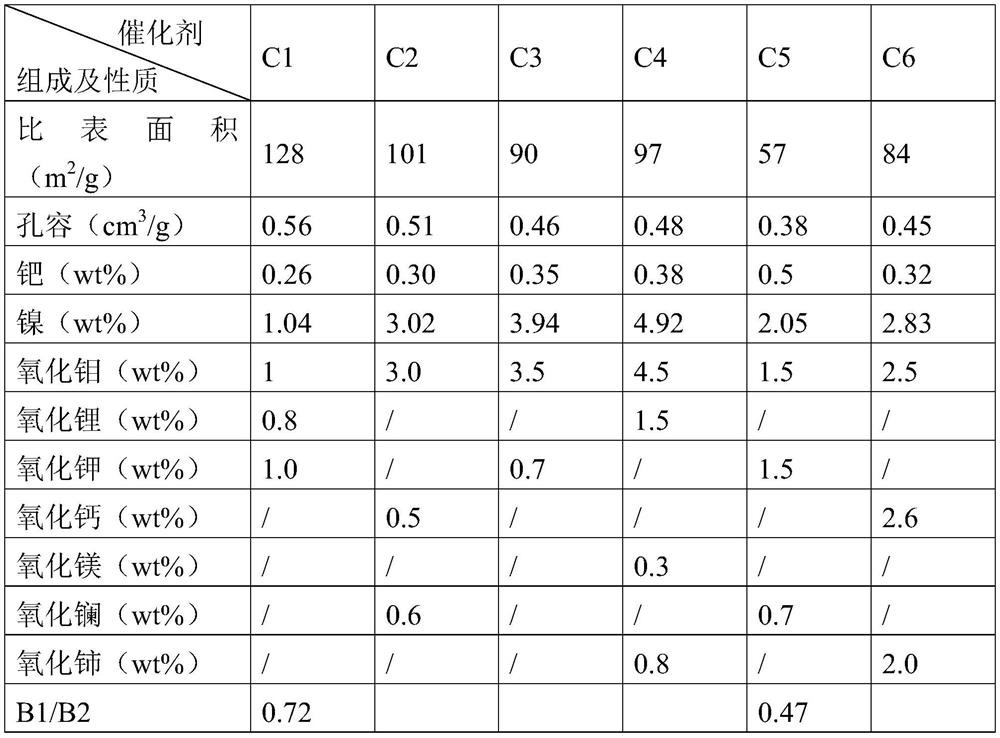

The invention relates to a hydrofining catalyst and a preparation method thereof. The invention is characterized in that: in the catalyst, silicon-containing alumina is taken as a carrier, cobalt, molybdenum and nickel are taken as active ingredients, and phosphorus and alkali metals and / or alkali earth metals are taken aids; the catalyst comprises the following components in percentage by weight: 1-4 percent of nickel oxide, 14-20 percent of molybdenum oxide, 1-6 percent of cobalt oxide, 0-5 percent of phosphorus oxide, 0-4 percent of alkali metal and / or alkali earth metal oxide and 3.1-33.6percent of silicon oxide; the specific surface area of the catalyst is 210-290 m<2> / g; and the pore volume is 0.55-0.78 ml / g. A silicon-containing alumina carrier precursor is pseudoboehmite which contains amorphous silica-alumina, and is obtained by preparing amorphous silica-alumina slurry and pseudoboehmite slurry, mixing the two types of slurry, aging, filtering, drying and the like. The catalyst has high hydrogenation activity and high stability, and is suitable for hydrofining of distillate oil.

Owner:PETROCHINA CO LTD

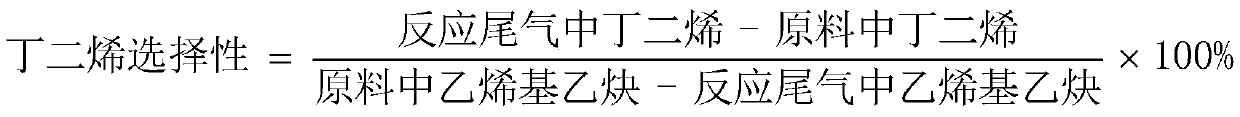

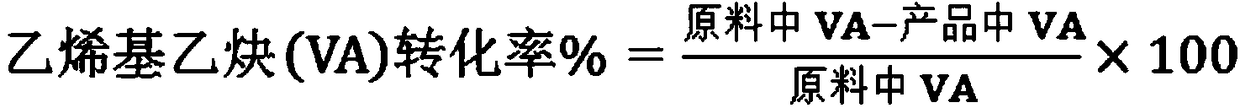

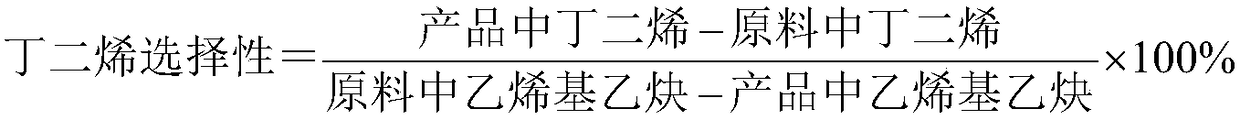

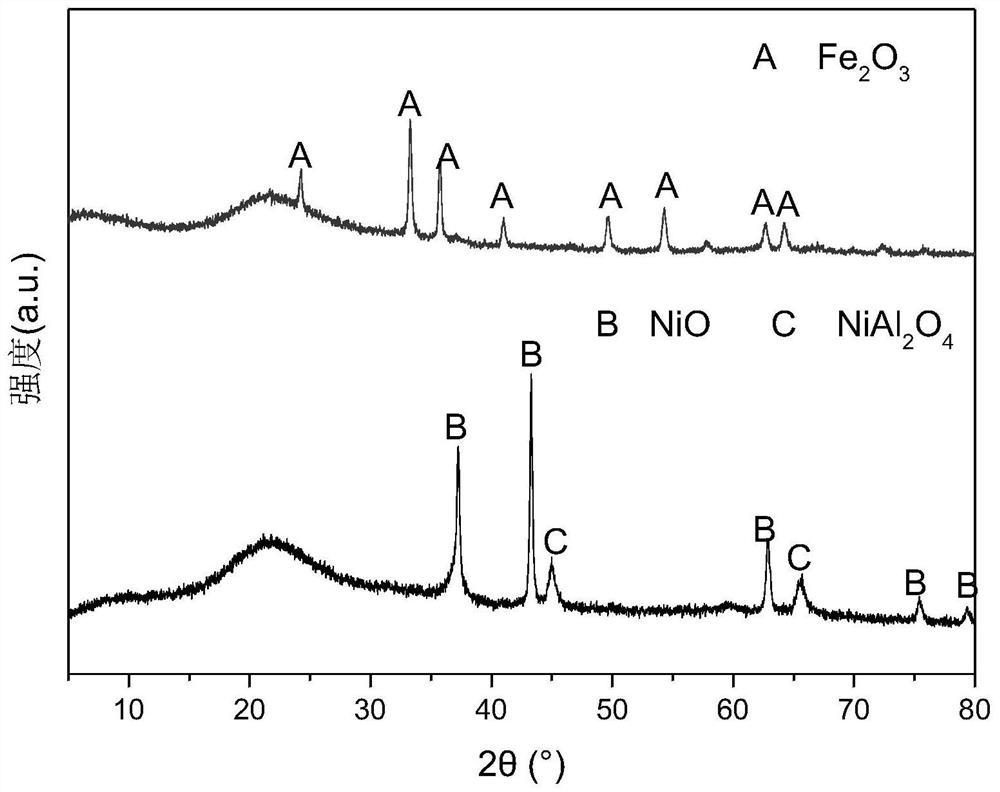

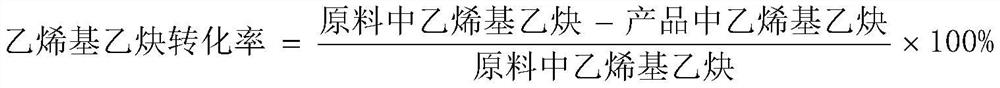

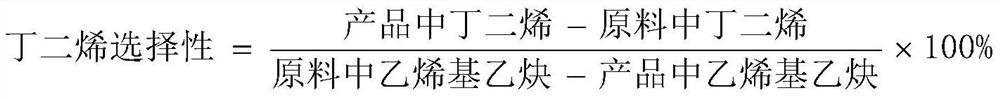

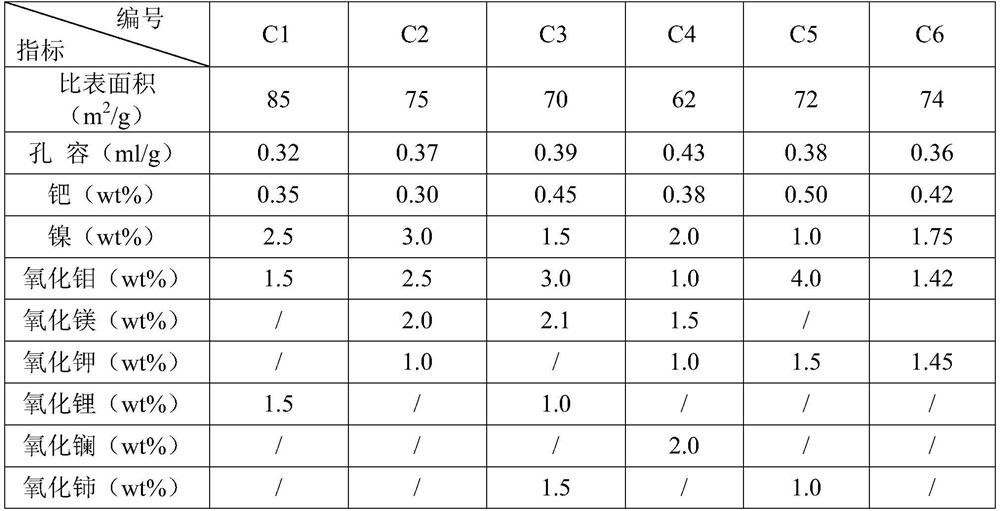

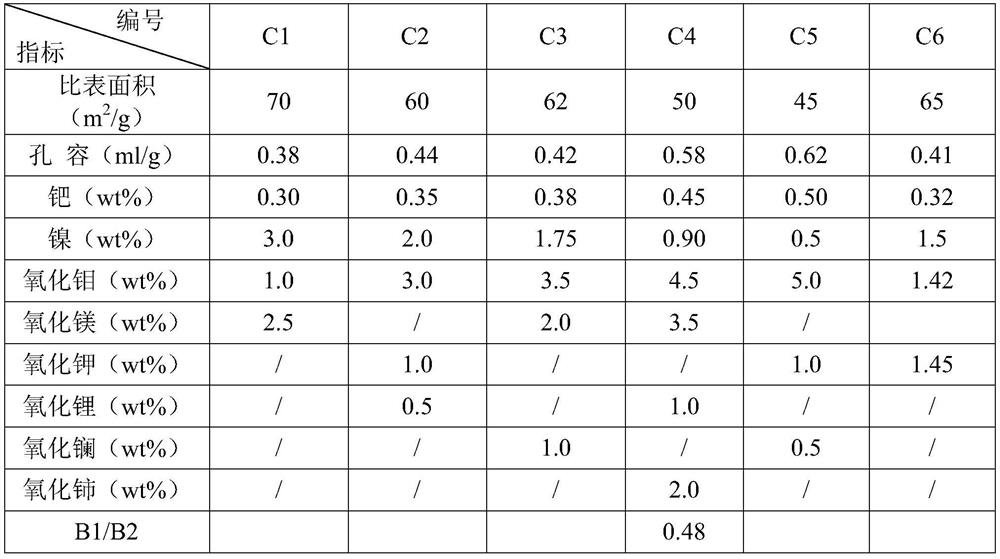

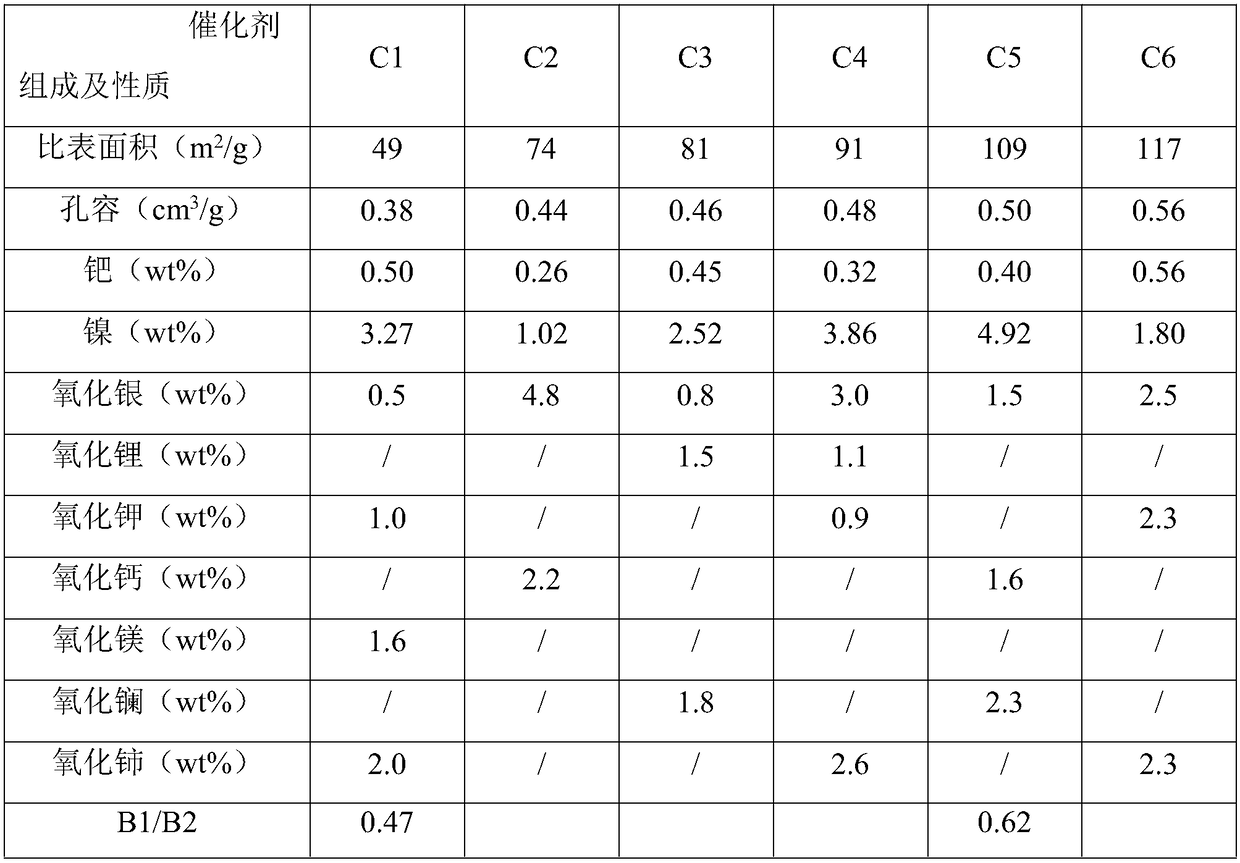

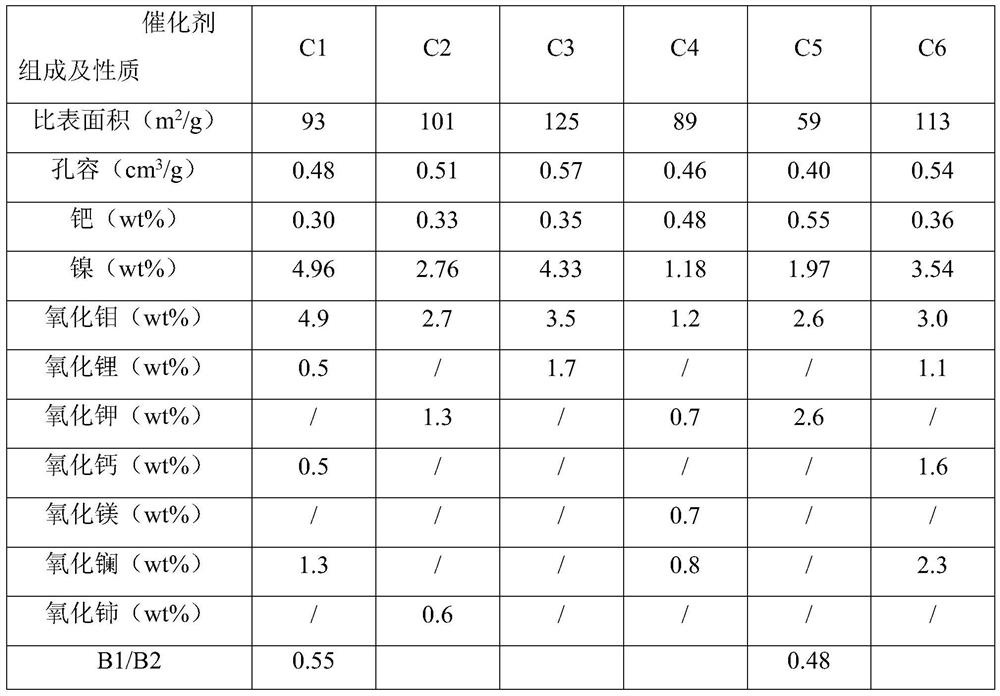

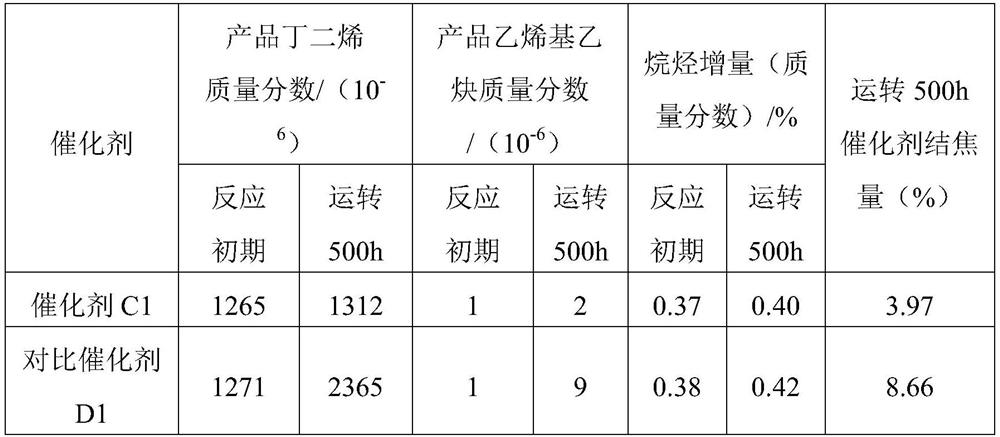

Catalyst for preparing butadiene through selective hydrogenation of C4 alkyne, preparation method and applications thereof

ActiveCN110813288AHigh selectivityStrong anti-coking performanceHydrocarbon by hydrogenationChemical recyclingButadiene DioxidePtru catalyst

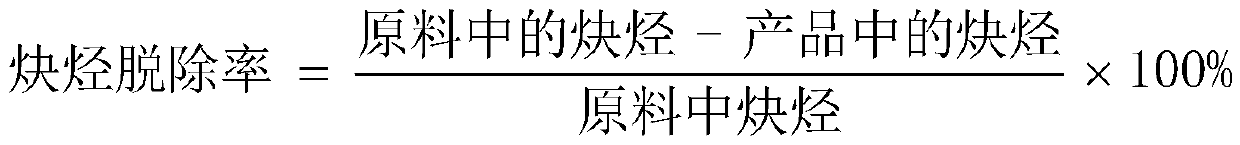

The invention relates to a catalyst for preparing butadiene through selective hydrogenation of C4 alkyne, a preparation method and applications thereof, wherein the catalyst comprises a ZrO2 / CdO / Bi2O3composite carrier and an active component, and the active component comprises: Pd or an oxide thereof, at least one selected from a VIIB metal or an oxide thereof, and La or an oxide thereof. According to the invention, the catalyst can be applied to selective hydrogenation of C4 alkyne to recover butadiene, and mainly solves the problems of poor stability, short service life, poor alkyne selectivity and overhigh butadiene loss of the catalyst in the prior art.

Owner:WANHUA CHEM GRP CO LTD

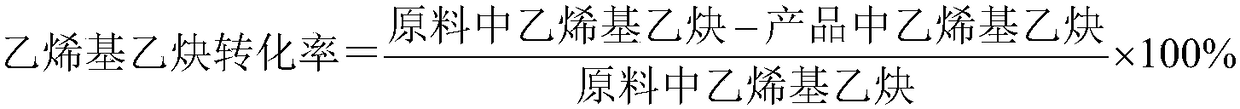

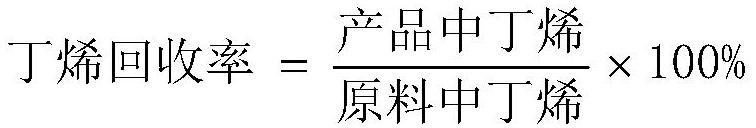

Method for increasing butadiene yield

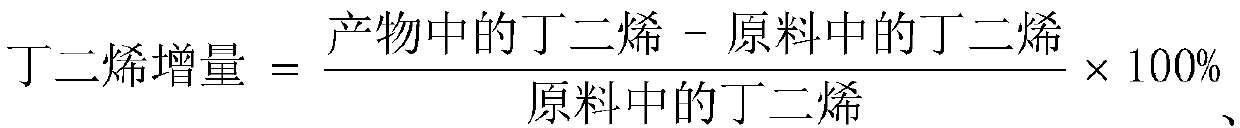

ActiveCN108863697ASuitable for acidityIncrease productionHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsDispersityAlkyne

The invention discloses a method for increasing butadiene yield. According to the method, carbon-4 cut fraction rich in alkyne after butadiene extraction is utilized as a raw material; under the existence of a catalyst, an adiabatic reactor is utilized, and selective hydrogenation is performed to obtain 1,3-butadiene; utilized hydrogenation operation conditions are that an inlet temperature of thereactor is 20 to 70 DEG C, reaction pressure is 0.8 to 3.0 MPa, and a liquid space velocity is 10 to 30 h<-1>. The catalyst is a palladium-silver-lead series catalyst which is prepared from a nickel-containing aluminum oxide carrier with a specific crystal form, so that dispersity and a utilization rate of active metal can be greatly improved, and hydrogenation performance of the catalyst is improved. The method disclosed by the invention has very obvious good effects on effectively utilizing carbon-4 cut fraction rich in alkyne after butadiene extraction, reducing resource waste and improving economical benefits.

Owner:PETROCHINA CO LTD

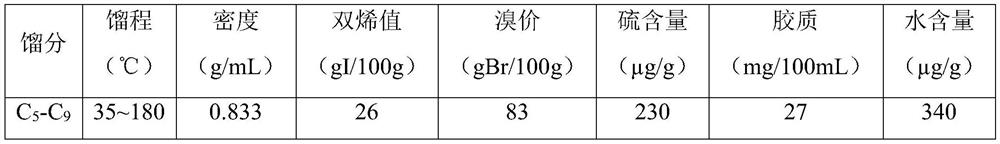

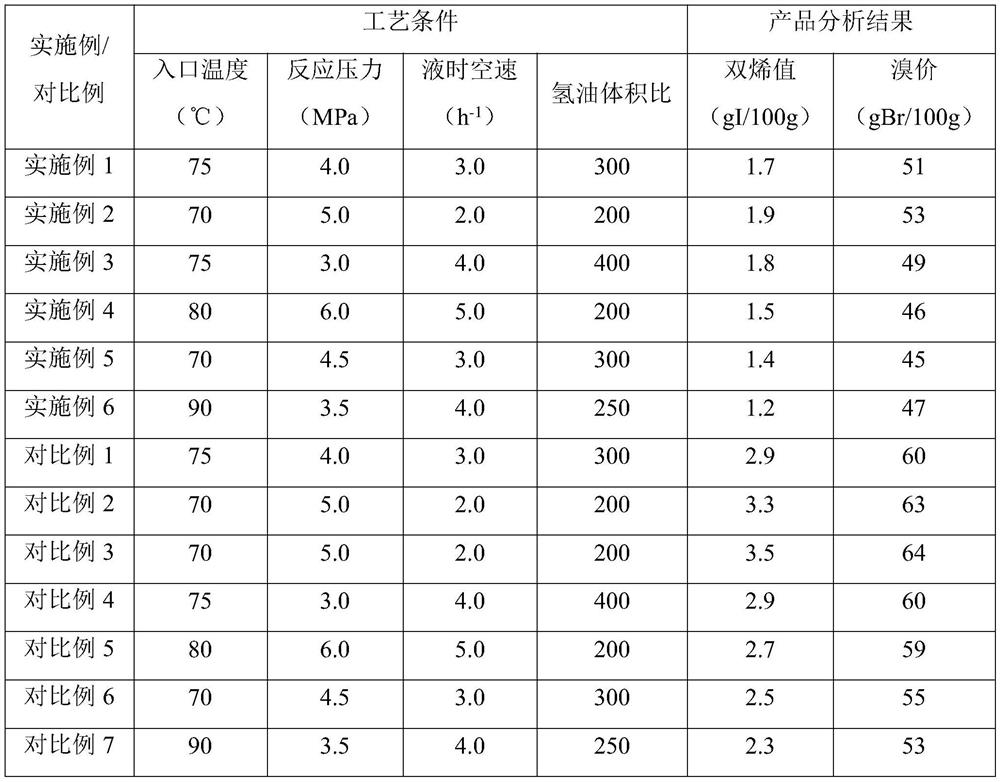

A sSelective hydrogenation method for pyrolysis gasoline

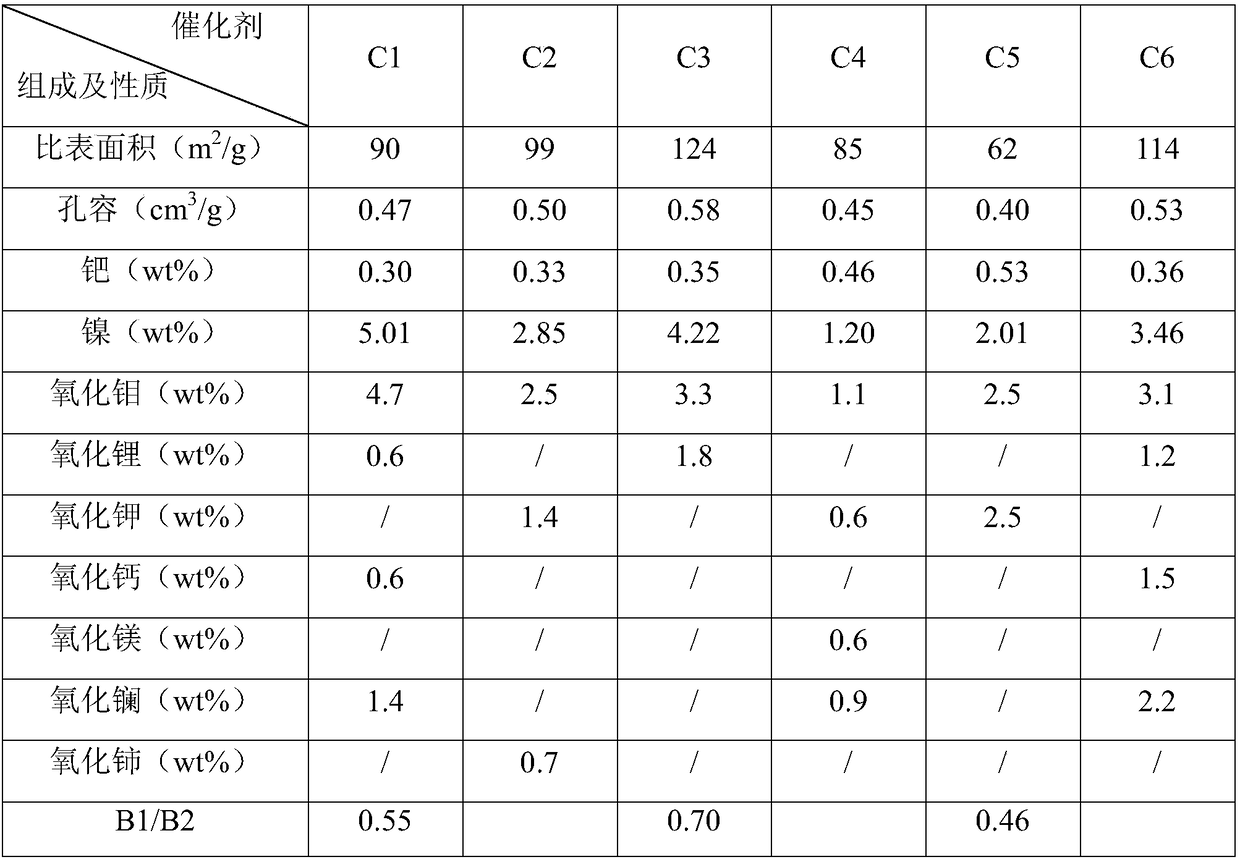

ActiveCN108865239AAppropriate pore size distributionSimple structureHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsDispersitySingle stage

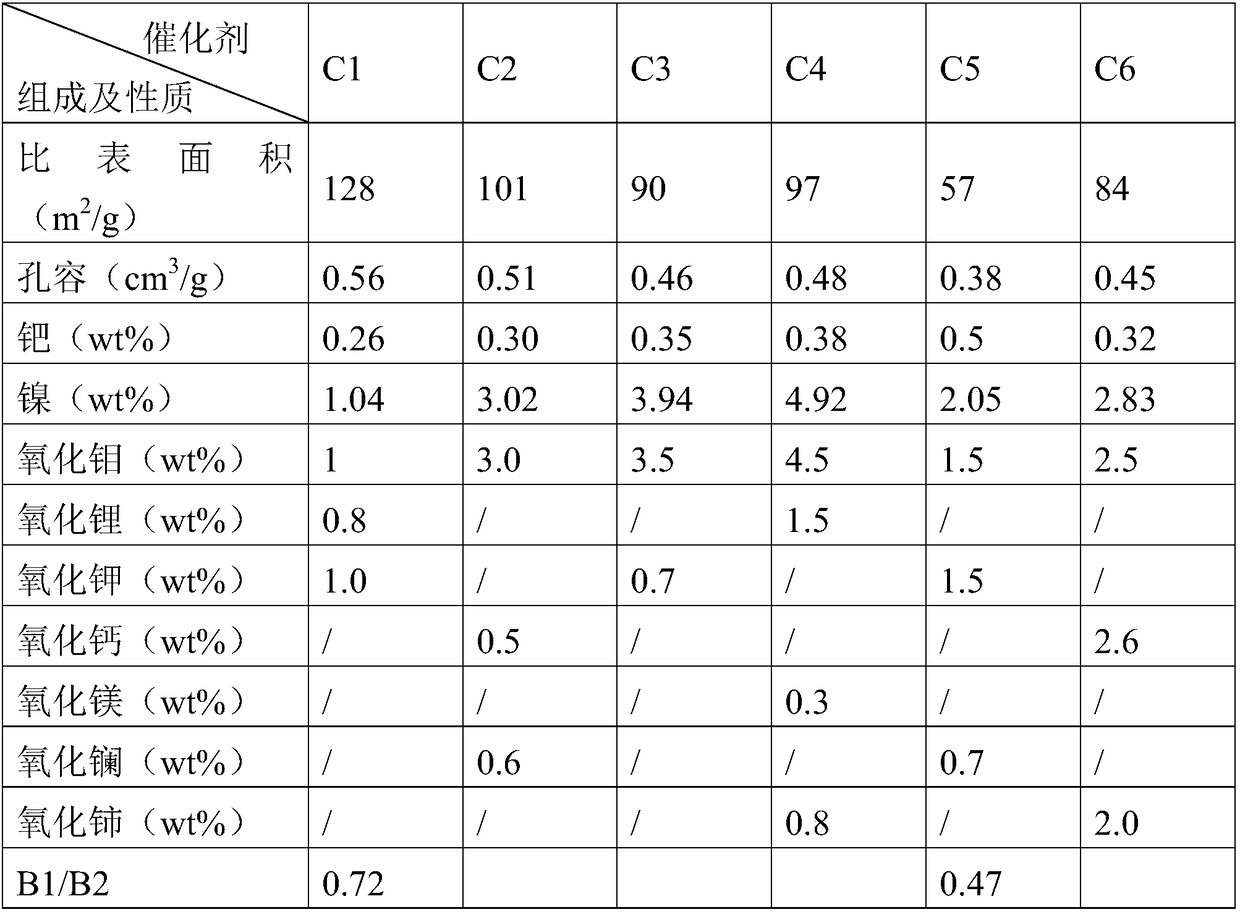

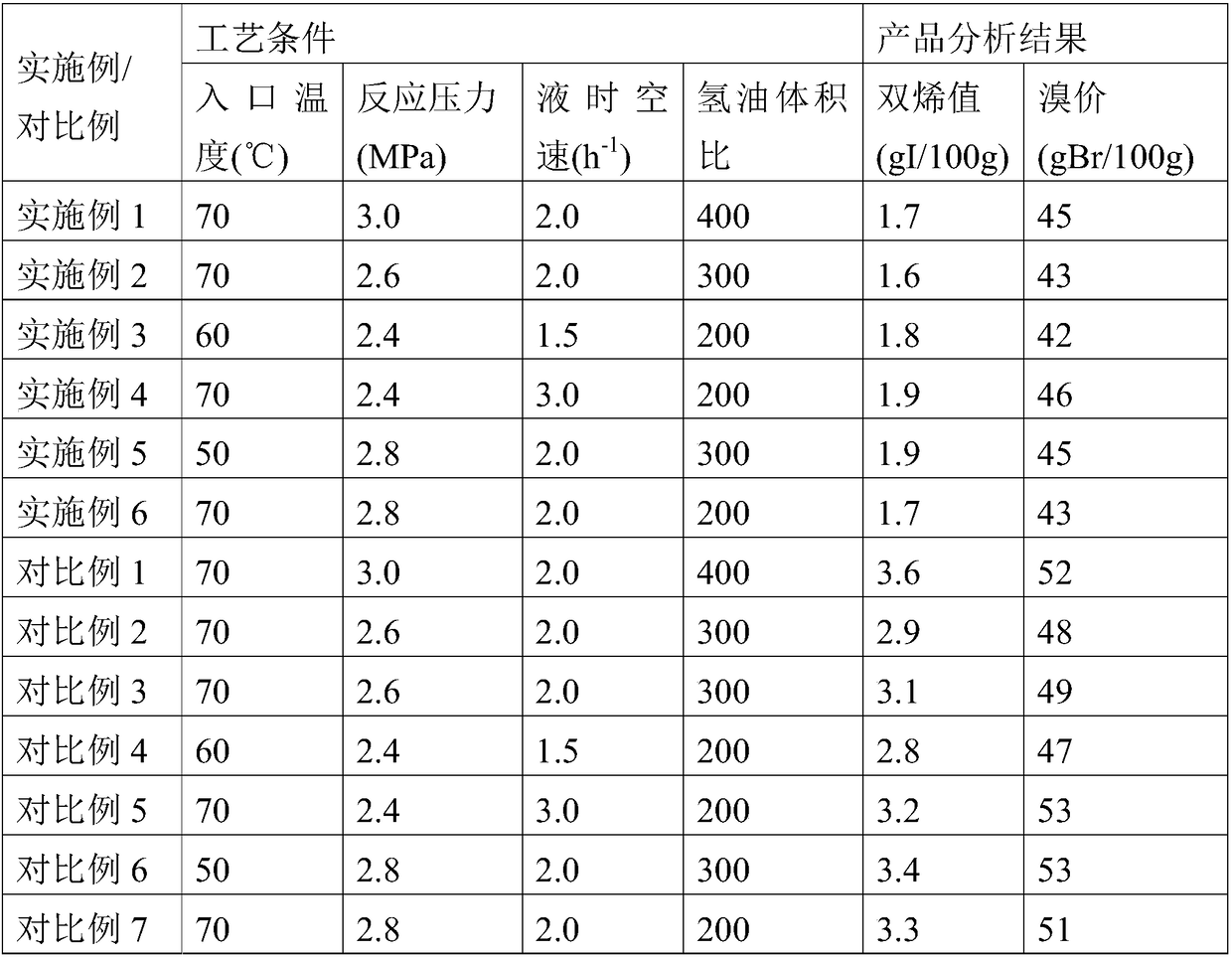

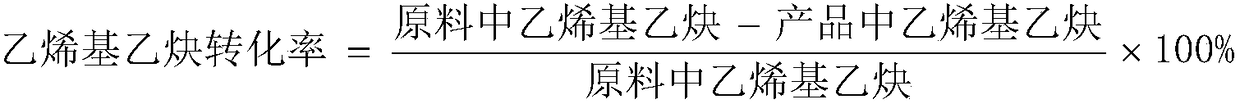

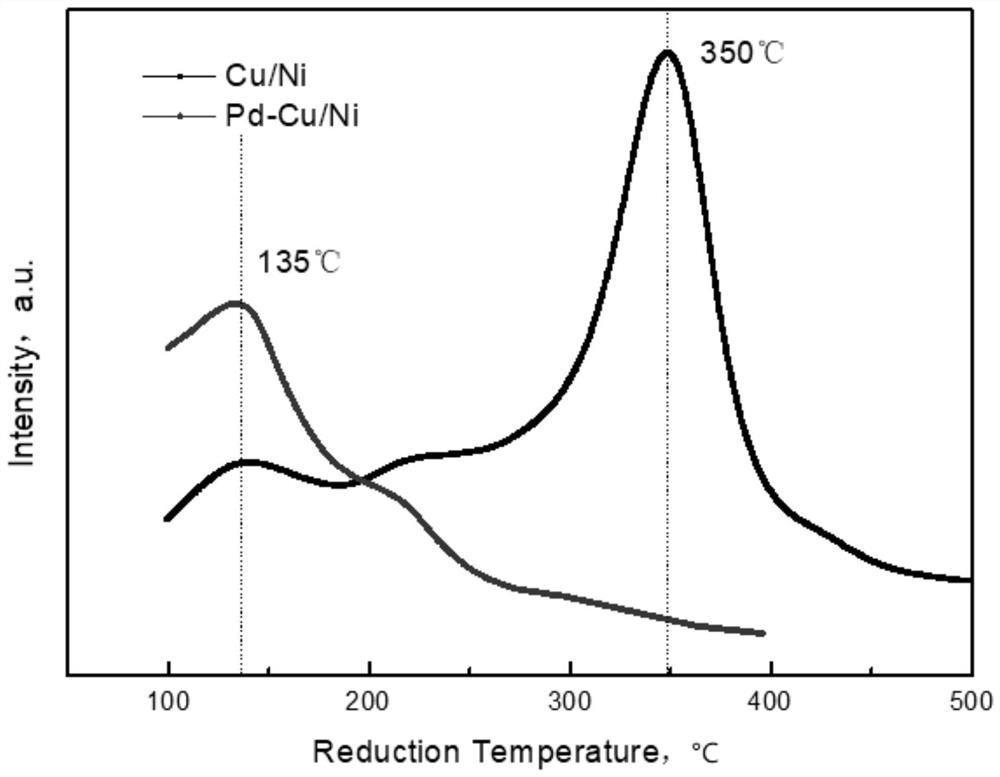

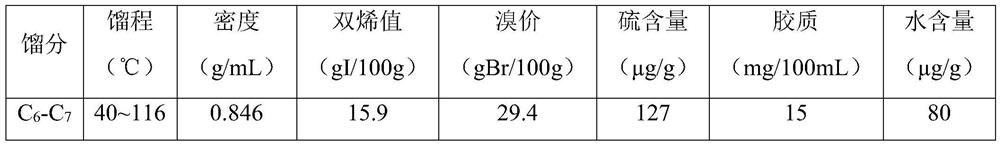

The invention provides a selective hydrogenation method for pyrolysis gasoline. A single-stage adiabatic fixed-bed reactor is adopted, and the reactor is provided with a Pd-Mo-based hydrogenation catalyst. The hydrogenation process conditions are as follows: reaction temperature 30-120 DEG C, reaction pressure 2-6 MPa, airspeed 0.5-4h-1, hydrogen-to-oil volume ratio (100-600):1. One part of the hydrogenation product is used as the inner cycle of a one-stage hydrogenation reaction, and the other part is sent to a second-stage hydrogenation reactor for hydrorefining. The catalyst having a specific crystal form prepared by using a nickel-containing alumina carrier in the invention can greatly improve the dispersion and utilization rate of active metals, and the addition of selected auxiliaryactive components which are added plays a synergistic role to improve the hydrogenation activity and stability of the catalyst.

Owner:PETROCHINA CO LTD

Method of recycling butadiene by alkyne selective hydrogenation

ActiveCN108863699ASuitable for acidityIncrease productionHydrocarbon by hydrogenationHydrocarbon purification/separationDispersityEconomic benefits

A method of recycling butadiene by alkyne selective hydrogenation, C-4 fraction rich in alkyne after butadiene extraction is taken as material to carry out selective hydrogenation to obtain 1,3-butadiene in an adiabatic reactor under the existence of a catalyst, with the process operation conditions: reaction inlet temperature is 20-60 DEG C, reaction pressure is 0.6-2.5 MPa, space velocity of liquid is 10-25h-1, wherein the catalyst is a palladium-molybdenum catalyst prepared with alumina supporter containing nickel and with specific crystal form that can greatly improve the dispersion and utilization of reactive metal and the hydrogenation performance of the catalyst. The method of recycling butadiene by the alkyne selective hydrogenation has extremely significant good effect on effectively utilization for C-4 fraction rich in alkyne after butadiene extraction, resource waste reduction and economic benefit improvement.

Owner:PETROCHINA CO LTD

Prehydrogenation treatment method for carbon-4 alkylation raw material

ActiveCN108865243AImprove thermal stabilityAperture ConcentrationHeterogenous catalyst chemical elementsCatalyst activation/preparationChemistryAlkyl transfer

The invention relates to a prehydrogenation treatment for a carbon-4 alkylation raw material. According to the prehydrogenation treatment method, a palladium-molybdenum series catalyst and a fixed bedreactor are utilized; hydrogenation process conditions are that a reaction temperature is 30 to 75 DEG C, reaction pressure is 1 to 3MPa, a liquid space velocity is 2 to 10h<-1>, and a molar ratio ofhydrogen to butadiene is 1 to 10; the palladium-molybdenum series catalyst is prepared from an aluminum oxide carrier containing nickel with a specific crystal form, so that the catalyst has appropriate acidity and a higher reactive metal utilization rate, and butadiene hydrogenation activity and selectivity of the catalyst are remarkably improved. By means of the hydrogenation treatment method disclosed by the invention, a carbon-4 alkylation raw material pretreatment device can effectively remove impurity butadiene at a higher feeding space velocity under the situation that monoolefine in ahydrogenation product is fundamentally not lost; thus, very obvious and good effects of improving environmental benefits and economic benefits of a follow-up alkylation device are achieved.

Owner:PETROCHINA CO LTD

Alkyne-containing C4 fraction selective hydrogenation method

ActiveCN108863706ASuitable for acidityImprove hydrogenation activityHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsDispersityReaction temperature

The invention relates to an alkyne-containing C4 fraction selective hydrogenation method. According to the method, rich-alkyne C4 fractions after butadiene extraction are used as raw materials; underthe existence of catalysts, an isothermal reactor is used; selective hydrogenation is performed to obtain 1,3-butadiene; the used process operation conditions are as followings: the reaction temperature is 30 to 75 DEG C, the reaction pressure is 1.0 to 3.0 MPa, and the liquid space velocity is 7 to 18h<-1>. The catalyst is a palladium-molybdenum series catalyst which is prepared from nickel-containing alumina carriers and has a specific crystal form; the dispersity and the utilization rate of active metal can be greatly improved; the hydrogenation performance of the catalyst is improved. Whenbeing used, the method has good effects that the rich-alkyne C4 fractions after butadiene extraction are effectively utilized; the resource waste is reduced; the economic benefits are greatly improved.

Owner:PETROCHINA CO LTD

Method of recycling butene by alkyne selective hydrogenation

ActiveCN108863696ASuitable for acidityImprove hydrogenation activityHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsDispersityChemistry

The invention discloses a method of recycling butene by alkyne selective hydrogenation, wherein the method takes C-4 fraction rich in alkynes after butadiene extraction as raw material to carry out alkynes and akadiene selective hydrogenation to obtain butene an adiabatic reactor under the action of catalyst, with the process operation conditions: reactor inlet temperature is 25-100 DEG C, reaction pressure is 0.6-2.5 MPa, space velocity of liquid to be 15-25h<-1>, wherein the catalyst is palladium-molybdenum-silver selective hydrogenation catalyst prepared with alumina supporter containing nickel and with specific crystal form that can greatly improve the dispersion and utilization of reactive metal and the hydrogenation performance of the catalyst. The method of recycling butene by the alkyne selective hydrogenation has extremely significant good effect on effectively utilization for C-4 fraction with rich alkynes after butadiene extraction, resource waste reduction and economic benefit improvement.

Owner:PETROCHINA CO LTD

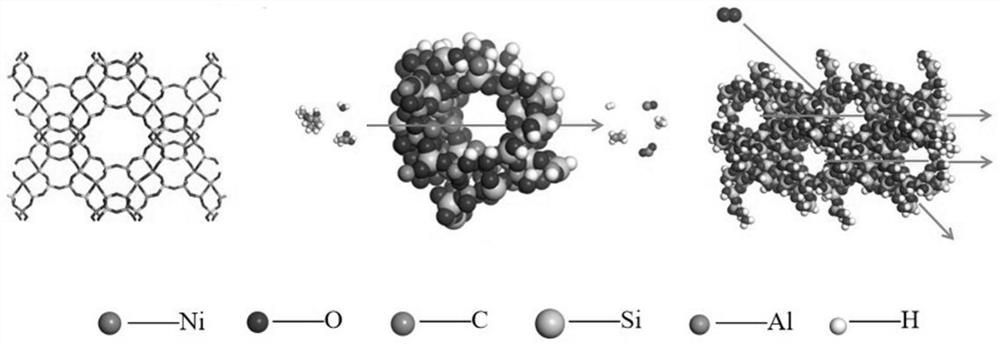

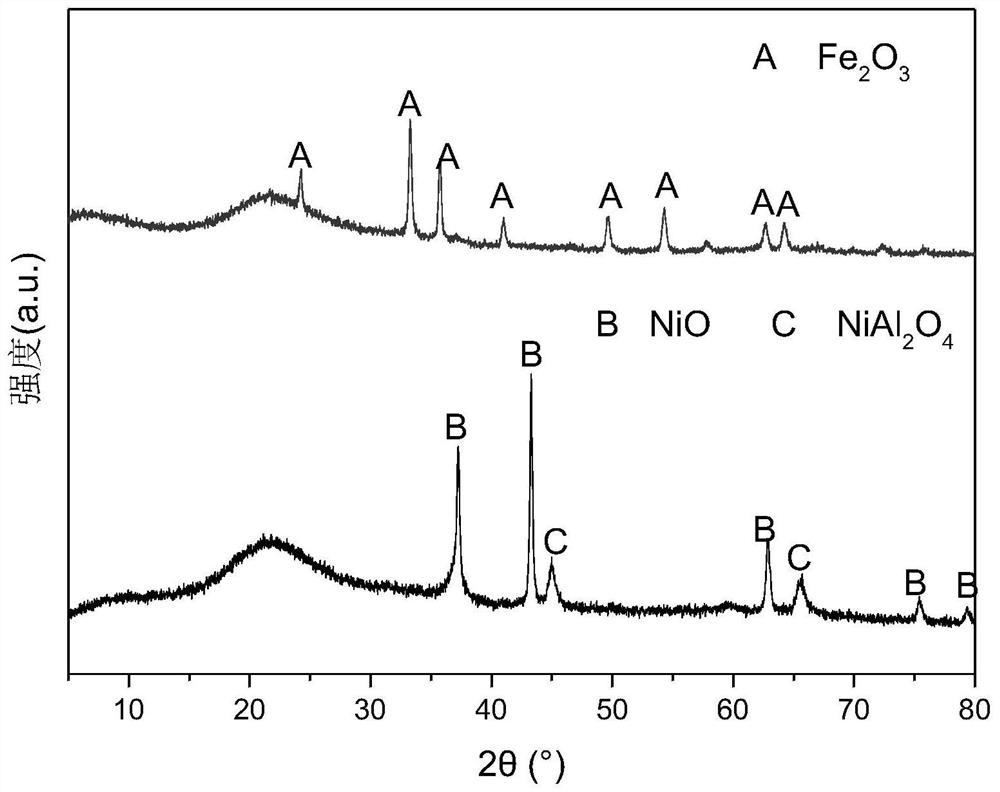

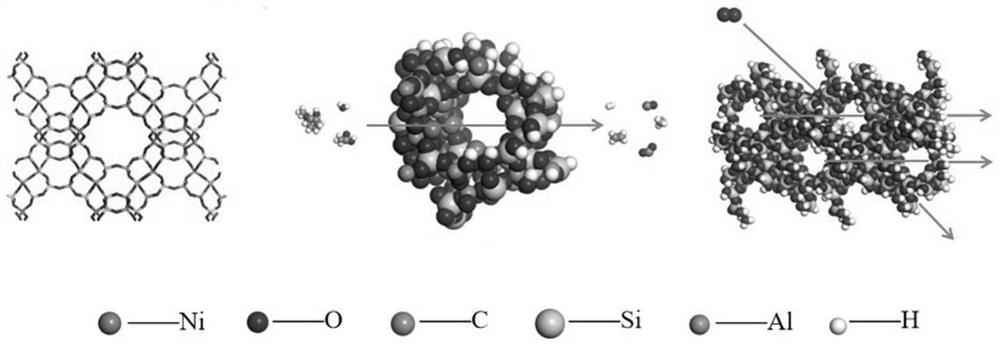

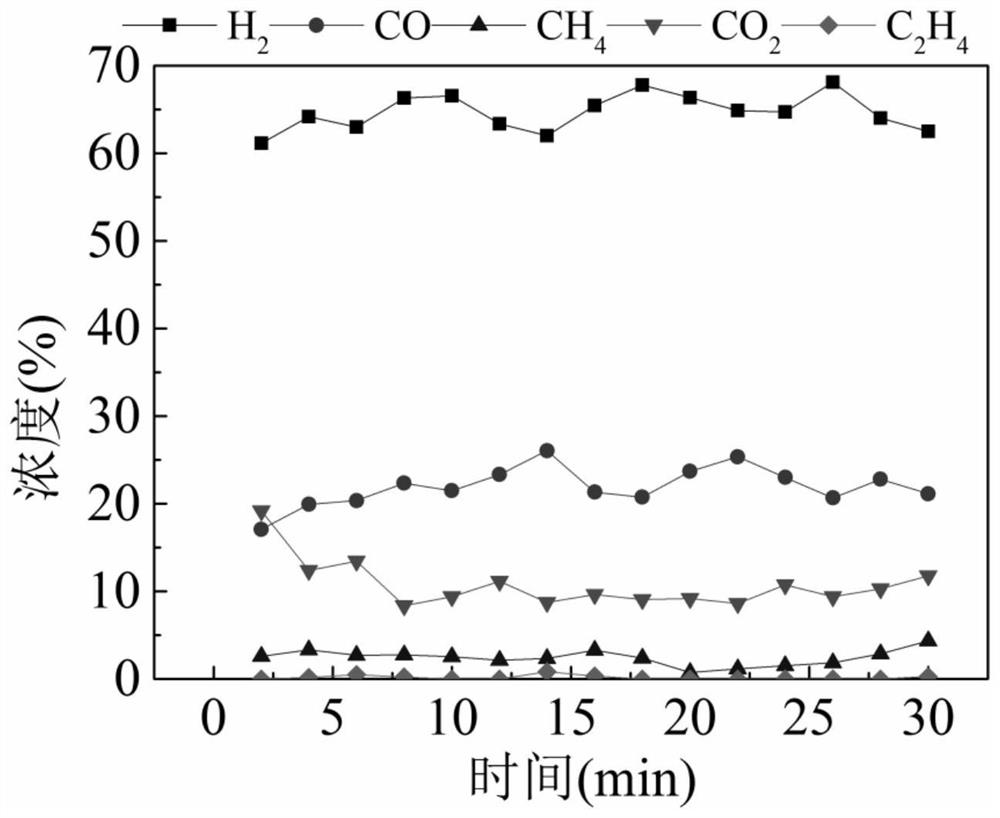

Nickel modified HY molecular sieve oxygen carrier with three-dimensional porous structure as well as preparation and application thereof

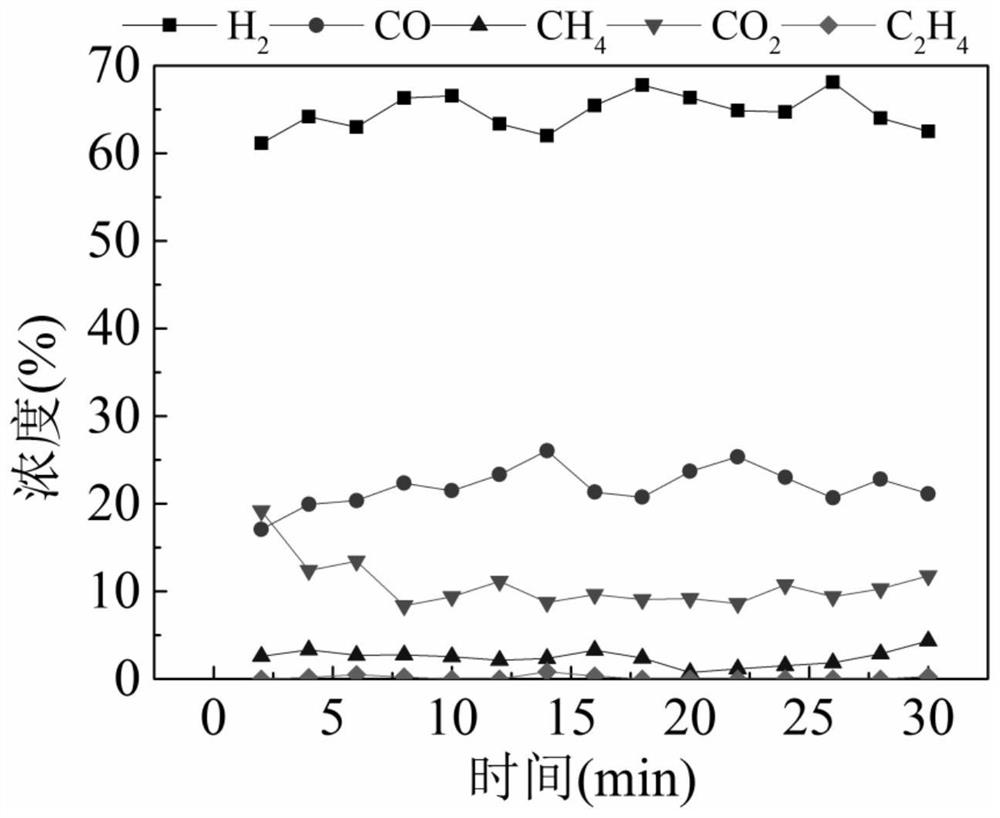

ActiveCN111974441AImprove catalysisImprove oxygen carrying capacityHydrogenMolecular sieve catalystsMolecular sieveFluid phase

The invention discloses a nickel modified HY molecular sieve oxygen carrier with a three-dimensional porous structure as well as preparation and application thereof. An HY molecular sieve is used as acarrier, transition metal is introduced to modify the molecular sieve, and the loading amount of the transition metal in the obtained metal modified HY oxygen carrier is 5-25%, thereby enhancing thecatalytic and oxygen-carrying capacities of the three-dimensional porous HY molecular sieve; a pyrolysis liquid phase product can be converted into hydrogen-rich synthesis gas under a certain reactioncondition; and the ratio of H2 to CO in the synthesis gas can be regulated and controlled to be about 0.5-3.0 by adjusting the reaction working condition, so that further Fischer-Tropsch synthesis isfacilitated.

Owner:SOUTH CHINA AGRI UNIV

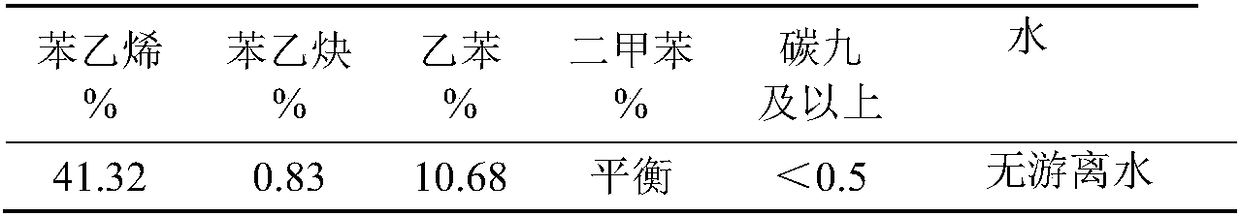

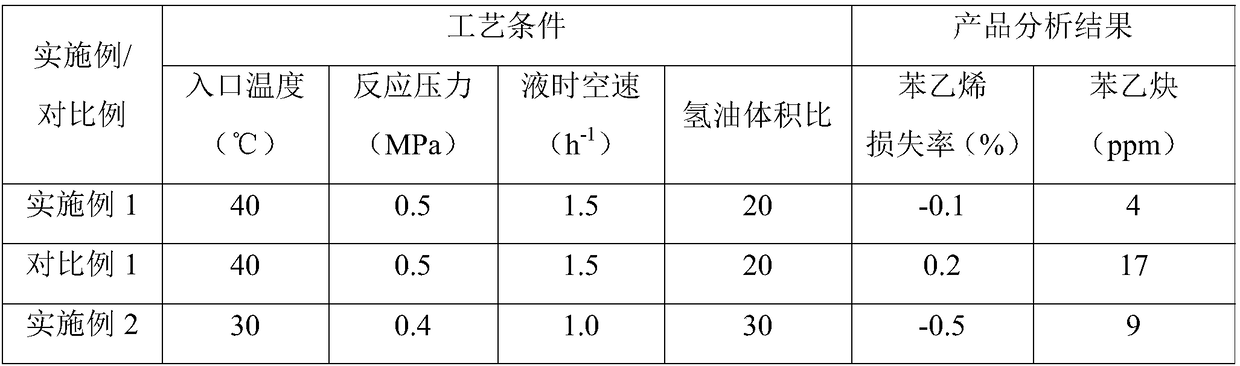

Selective hydrogenation method for pyrolysis gasoline C8 fraction

ActiveCN108865241AAppropriate pore size distributionImprove hydrogenation performanceMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationFixed bedRaw material

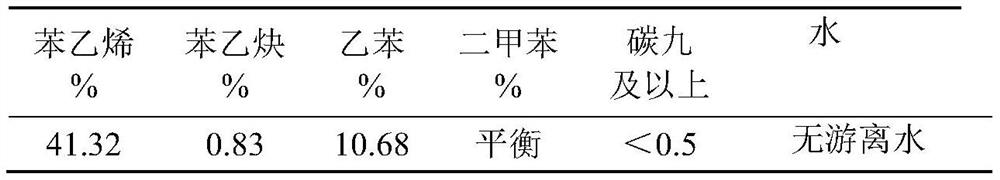

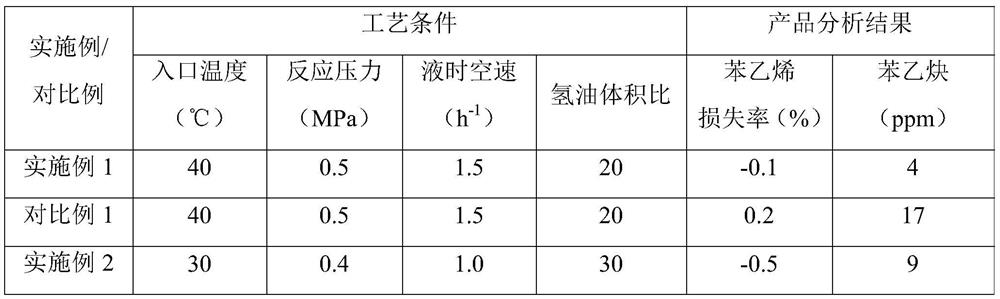

The invention provides a method for selective hydrogenation for phenylacetylene removal by using a raw material of pyrolysis gasoline C8 fraction, wherein the C8 fraction is preheated and enters a fixed bed hydrogenation reactor, a lower feeding mode is adopted, and the reactor is filled with a catalyst; hydrogenation process conditions are: inlet temperature is 10-70 DEG C, space velocity is 0.1-6.0h<-1>, pressure is between 0.1 and 2.0 MPa, the volume ratio of hydrogen to fresh oil is (1-100):1, and a hydrogenation product is a raw material for extracting styrene; Pd-Mo series catalysts prepared by using a nickel-containing alumina carrier having a specific crystalline form prepared by the selective hydrogenation method for the pyrolysis gasoline C8 fraction can greatly improve the dispersion and utilization ratio of active metal, and active components are added to play synergistic effects to improve hydrogenation activity and selectivity of the catalyst.

Owner:PETROCHINA CO LTD

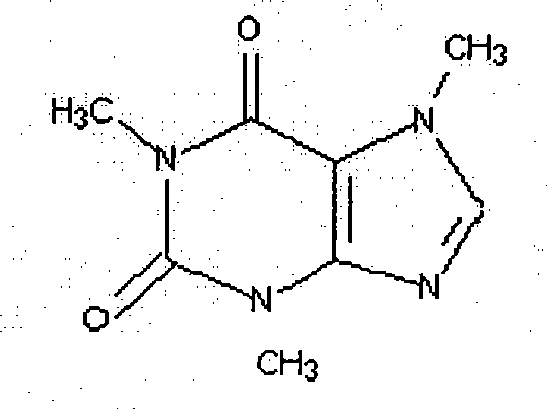

Catalyst system used for synthesizing acetic acid and acetic anhydride and application thereof

InactiveCN101143339ASmall areaLittle change in pore volumeOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic acid anhydrides preparationAcetic anhydrideProtein carbonyl

The present invention discloses a catalyst system used for acetic acid and acetic anhydride synthesis and the application. Halide of rhodium is used for active specie of a catalyst and alkyl halide, alkali metal iodine and organic solvent are used as the catalyst. Caffeine is used as a ligand. The mass proportion of the caffeine and the halide of the rhodium is one till thirty to one. The catalyst system provided by the present invention has the advantage of good compatibility. The hard removing problems of the wall attachment, the falling to the bottom and the coking of the catalyst are not easy to happen in carbonylation reaction equipment. And the present invention has the advantages of high catalytic activity, high selectivity, high thermal stability and strong anti-coking performance. Any complex pretreatment before the catalysis is not needed. The formation of the catalyst system is simple and rapid. The catalyst process is simple and easy to be implemented. And the present invention also has the advantages of high catalytic activity, high stability, good compatibility, low cost, etc.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

A three-dimensional porous structure nickel-modified hy molecular sieve oxygen carrier and its preparation and application

ActiveCN111974441BImprove oxygen carrying capacityEasy to synthesizeHydrogenMolecular sieve catalystsMolecular sieveFluid phase

The invention discloses a nickel-modified HY molecular sieve oxygen carrier with a three-dimensional porous structure and its preparation and application. In the present invention, HY molecular sieve is used as a carrier, and transition metals are introduced to modify the molecular sieve at the same time. The loading capacity of the transition metal in the obtained metal-modified HY oxygen carrier is 5-25%, which improves the catalytic and oxygen-carrying capacity of the three-dimensional porous HY molecular sieve. It can realize the conversion of pyrolysis liquid phase products into hydrogen-rich synthesis gas under certain reaction conditions. By adjusting the reaction conditions, the H in the synthesis gas can be 2 The ratio of / CO is regulated at about 0.5-3.0, which is beneficial to further Fischer-Tropsch synthesis.

Owner:SOUTH CHINA AGRI UNIV

A method for selective hydrogenation of alkyne-containing carbon tetrafraction

ActiveCN108863706BSuitable for acidityImprove hydrogenation activityHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsPtru catalystButadiene Dioxide

A method for selective hydrogenation of alkyne-containing carbon tetrafraction, using butadiene-rich alkyne-rich carbon tetrafraction as a raw material, in the presence of a catalyst, using an isothermal reactor, selective hydrogenation to obtain 1,3- For butadiene, the operating conditions of the process are as follows: the reaction temperature is 30-75°C, the reaction pressure is 1.0-3.0MPa, and the liquid space velocity is 7-18h ‑1 . The catalyst is a palladium-molybdenum catalyst prepared on a nickel-containing alumina carrier with a specific crystal form, which can greatly improve the dispersion and utilization of active metals, and improve the hydrogenation performance of the catalyst. Adopting the method of the invention has very obvious good effects on the effective utilization of the C4 fraction rich in alkynes after the extraction of butadiene, reduction of waste of resources and improvement of economic benefits.

Owner:PETROCHINA CO LTD

A kind of method of alkyne selective hydrogenation recovery butadiene

ActiveCN108863699BSuitable for acidityIncrease productionHydrocarbon by hydrogenationHydrocarbon purification/separationPtru catalystButadiene Dioxide

A method for recovering butadiene by selective hydrogenation of alkynes, using the C4 fraction rich in alkynes after extraction of butadiene as a raw material, in the presence of a catalyst, using an adiabatic reactor, selective hydrogenation to obtain 1,3 ‑Butadiene, the operating conditions of the process are as follows: the reaction inlet temperature is 20-60°C, the reaction pressure is 0.6-2.5MPa, and the liquid space velocity is 10-25h ‑1 . The catalyst is a palladium-molybdenum catalyst prepared on a nickel-containing alumina carrier with a specific crystal form, which can greatly improve the dispersion and utilization of active metals, and improve the hydrogenation performance of the catalyst. Adopting the method of the invention has very obvious good effects on the effective utilization of the C4 fraction rich in alkynes after the extraction of butadiene, the reduction of waste of resources and the improvement of economic benefits.

Owner:PETROCHINA CO LTD

A kind of carbon tetrayne selective hydrogenation to butadiene catalyst and preparation method and application

ActiveCN110813288BHigh selectivityStrong anti-coking performanceHydrocarbon by hydrogenationChemical recyclingButadiene DioxidePtru catalyst

The invention relates to a catalyst for preparing butadiene by selective hydrogenation of carbon tetrayne and a preparation method and application. The catalyst includes ZrO 2 / CdO / Bi 2 O 3 A composite carrier and an active component, the active component consists of: at least one of Pd or its oxide, VIIB metal or its oxide, La or its oxide. The catalyst of the invention can be used in the application of the selective hydrogenation of carbon tetraacetylene to recover butadiene, and mainly solves the problems of poor catalyst stability, short life, poor alkyne selectivity and excessive butadiene loss in the prior art.

Owner:WANHUA CHEM GRP CO LTD

Selective hydrogenation method

ActiveCN108865242AAppropriate pore size distributionImprove hydrogenation performanceHeterogenous catalyst chemical elementsRefining by selective hydrogenationDispersityHydrogenation reaction

The invention provides a selective hydrogenation method. According to the selective hydrogenation method, a fixed bed reactor is utilized, a Pd-Ag series hydrogenation catalyst is put into the reactor, and pyrolysis gasoline and hydrogen enter the reactor after being mixed and preheated; the hydrogenation technological conditions are that a reaction temperature is 30 to 120 DEG C, reaction pressure is 2 to 6MPa, a space velocity is 0.5 to 4h<-1>, and a volume ration of hydrogen to oil is (100 to 600) to 1; one part of a hydrogenated product serve as internal circulation of a one-stage hydrogenation reaction, and the other part of the hydrogenated product is sent into a two-stage hydrogenation reactor to be hydrogenated and refined. By means of the catalyst which is prepared from the specific crystal form nickel-containing aluminum oxide carrier prepared by the selective hydrogenation method disclosed by the invention, dispersity and a utilization rate of reactive metal are greatly improved; meanwhile, selected activity assisting ingredients are added to achieve a synergistic effect, and hydrogenation performance and selectivity of the catalyst are improved.

Owner:PETROCHINA CO LTD

Catalyst system used for synthesizing acetic acid and acetic anhydride and application thereof

InactiveCN101143339BImprove stabilityLow preparation costOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic acid anhydrides preparationAcetic anhydrideProtein carbonyl

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

Method of producing catalytic reforming raw materials

ActiveCN102352265BReduce energy consumptionEasy to operateCatalyst carriersCatalyst activation/preparationCatalytic reformingAlkaline earth metal

The invention provides a method of producing catalytic reforming raw materials. According to the method, hydrotreatment is carried out on the raw materials once and for all. Conditions for a hydrotreatment process are as follows: temperature of a reaction inlet is 200 to 320 DEG C; operational pressure is greater than 2.4 MPa; volume space velocity of fresh raw oil is 4 to 12 / h; a volume ratio of hydrogen to oil is 50 to 300. A hydrotreatment catalyst employed in the invention uses silicon-containing alumina as a carrier, nickel and tungsten as active components, and phosphor and alkali metals and / or alkaline earth metals as auxiliary agents. The method provided in the invention can treat high sulfur- and nitrogen-containing catalytic reforming raw materials which contain a great amount of alkene at the condition of low pressure, and provides qualified raw materials in which sulfur content and nitrogen content are both less than 0.5 mu g / g for a catalytic reforming unit.

Owner:PETROCHINA CO LTD

Hydrorefining method of middle and low distillate oil

ActiveCN102268284BImprove hydrogenation activityImprove stabilityPhysical/chemical process catalystsHydrocarbon oils treatmentSlurryAlkali metal

The invention provides a hydrorefining method of middle and low distillate oil. The hydrorefining method is characterized in that a used catalyst is a molybdenum nickel hydrogenation catalyst; hydrogenation process conditions are as follows: an inlet temperature is 200-300 DEG C, an operation pressure is larger than or equal to 2.4MPa, the volume space speed of a liquid is 1-5 h<-1>, and the volume ratio of hydrogen to oil is 100-500; in the molybdenum nickel catalyst, silicon-containing alumina is a carrier, molybdenum and nickel are active components, and phosphorus and alkali metals are auxiliaries; and the precursor of the silicon-containing alumina carrier is pseudoboehmite containing amorphous silicon and aluminum and is obtained by the steps of firstly preparing an amorphous silicon and aluminum slurry and a pseudoboehmite slurry, mixing the slurries and then ageing, and then carrying out post-treatment processes such as filtering, washing and drying. By using the method, hydrorefining is carried out on a first-section hydrogenation product of cracked gasoline containing middle and low distillates, wherein the bromine value of the hydrogenation product is less than 1.0*10<-2>g / g, and the sulfur content of the hydrogenation product is less than 1.0mu g / g, thereby meeting the second-section hydrogenation requirement of cracked gasoline.

Owner:PETROCHINA CO LTD

Selective hydrogenation method

PendingCN114075451ASimple structureIncrease production capacityHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystFixed bed

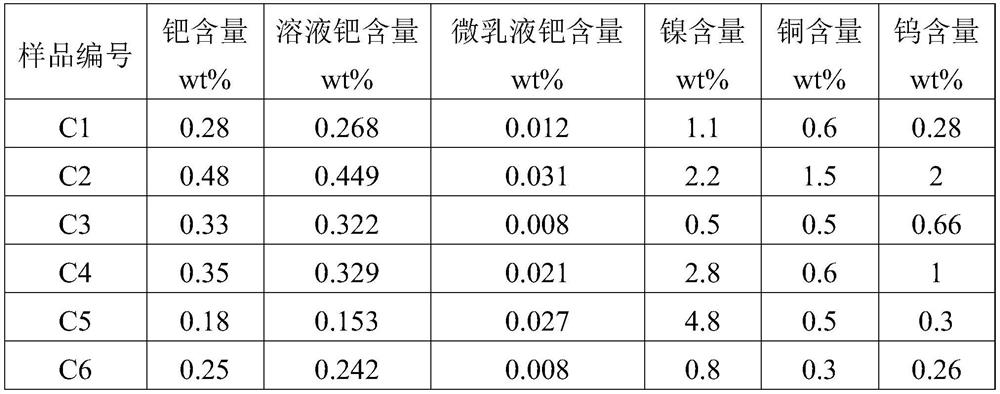

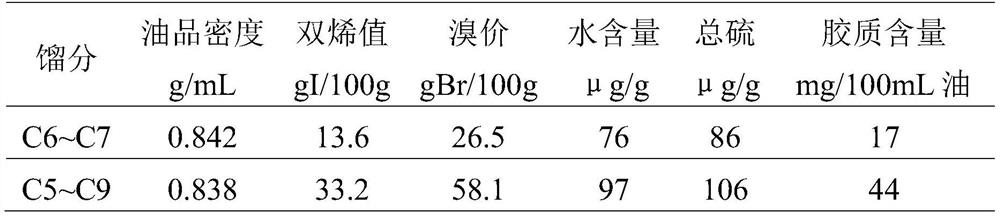

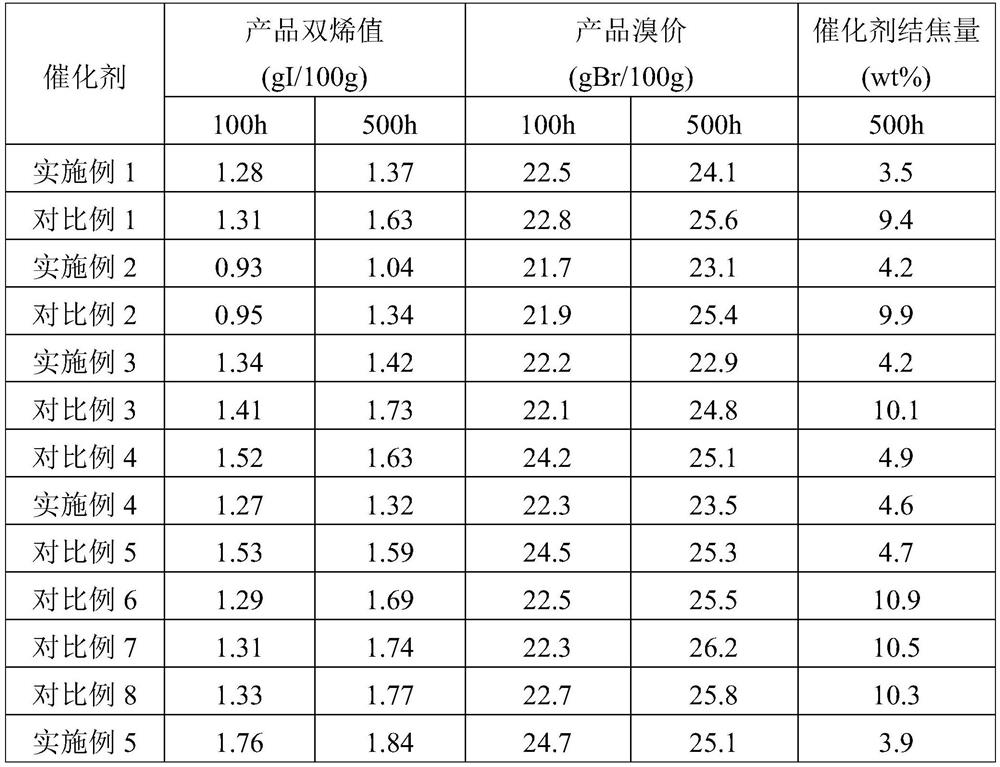

The invention provides a selective hydrogenation method, which adopts a fixed bed reactor, wherein the reactor is filled with a hydrogenation catalyst which has a bimodal pore distribution structure and at least contains Pd, W, Ni and Cu, pyrolysis gasoline and hydrogen are mixed and preheated and then enter the reactor, and the hydrogenation process conditions are that the reaction temperature is 30-120 DEG C, the reaction pressure is 2-6 MPa, the air speed is 0.5-4 h<-1>, and the volume ratio of hydrogen to oil is (100-600):1. According to the invention, a catalyst carrier used in the hydrogenation method is alumina or mainly alumina and has a bimodal pore distribution structure, active components of the catalyst at least contain Pd, W, Ni and Cu, and the hydrogenation method is characterized in that Ni and Cu are loaded in a microemulsion manner, so that Ni and Cu are mainly distributed in the macropores of the carrier; W is loaded by a solution method, Pd is loaded by a solution method and a microemulsion method, most of Pd is loaded by the solution method, and a small part of Pd is loaded by the microemulsion method; and the hydrogenation method has the characteristics of high hydrogenation activity, good selectivity and strong operation stability.

Owner:PETROCHINA CO LTD

A kind of method of alkyne selective hydrogenation recovery butene

ActiveCN108863696BSuitable for acidityImprove hydrogenation activityHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsPtru catalystAlkyne

A method for the selective hydrogenation of alkynes to recover butenes, using the C4 fraction rich in alkynes after the extraction of butadiene as a raw material, in the presence of a catalyst, using an adiabatic reactor to selectively hydrogenate alkynes and dienes The hydrogen is butene, and the operating conditions of the process are as follows: the reactor inlet temperature is 25-100°C, the reaction pressure is 0.6-2.5MPa, and the liquid space velocity is 15-25h ‑1 . The catalyst is a palladium-molybdenum-silver selective hydrogenation catalyst prepared on a nickel-containing alumina carrier with a specific crystal form, which can greatly improve the dispersion and utilization of active metals and improve the hydrogenation performance of the catalyst. Adopting the method of the invention has very obvious good effects on the effective utilization of the C4 fraction rich in alkynes after the extraction of butadiene, reduction of waste of resources and improvement of economic benefits.

Owner:PETROCHINA CO LTD

A method for increasing production of butadiene

ActiveCN108863697BSuitable for acidityIncrease productionHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsPtru catalystButadiene Dioxide

A method for increasing the production of butadiene, using the alkyne-rich C4 fraction after the extraction of butadiene as a raw material, in the presence of a catalyst, using an adiabatic reactor, selective hydrogenation to obtain 1,3-butadiene, The operating conditions for hydrogenation are as follows: the reactor inlet temperature is 20-70°C, the reaction pressure is 0.8-3.0MPa, and the liquid space velocity is 10-30h ‑1 . The catalyst is a palladium-silver-lead catalyst prepared on a nickel-containing alumina carrier with a specific crystal form, which can greatly improve the dispersion and utilization of active metals and improve the hydrogenation performance of the catalyst. Adopting the method of the invention has very obvious good effects on the effective utilization of the C4 fraction rich in alkynes after the extraction of butadiene, the reduction of waste of resources and the improvement of economic benefits.

Owner:PETROCHINA CO LTD

A method for selective hydrogenation of pyrolysis gasoline

ActiveCN108865240BImprove hydrogenation performanceImprove stabilityHeterogenous catalyst chemical elementsRefining by selective hydrogenationPtru catalystHydrogenation reaction

The invention provides a method for selective hydrogenation of pyrolysis gasoline, which adopts an isothermal fixed-bed reactor. The reactor is equipped with a Pd-Mo series hydrogenation catalyst. The hydrogenation process conditions are: reaction temperature 50-100°C, reaction pressure 3 ~7MPa, airspeed 1~5h ‑1 , the volume ratio of hydrogen to oil is 100~600:1; the hydrogenated product is sent to the two-stage hydrogenation reactor for hydrogenation and refinement. The Pd-Mo series hydrogenation catalyst prepared by using the nickel-containing alumina carrier with a specific crystal form prepared by the present invention can greatly improve the dispersion and utilization rate of active metals, and at the same time, the addition of selected auxiliary active components can Synergistic effect to improve the hydrogenation activity and stability of the catalyst.

Owner:PETROCHINA CO LTD

Selective Hydrogenation Method of Pyrolysis Gasoline

ActiveCN108865239BSimple structureIncrease production capacityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogenation reaction

The invention provides a method for selective hydrogenation of pyrolysis gasoline, which adopts a single-stage adiabatic fixed-bed reactor. The reactor is equipped with a Pd-Mo series hydrogenation catalyst. The hydrogenation process conditions are: reaction temperature 30-120°C, reaction Pressure 2~6MPa, airspeed 0.5~4h ‑1 , the volume ratio of hydrogen to oil is 100~600:1; part of the hydrogenation product is used as an internal cycle of the first-stage hydrogenation reaction, and the other part is sent to the second-stage hydrogenation reactor for hydrogenation and refining. The catalyst prepared by using the nickel-containing alumina carrier with a specific crystal form prepared by the present invention can greatly improve the dispersion and utilization rate of active metals. At the same time, the addition of selected co-active components has a synergistic effect and improves the performance of the catalyst. Hydrogenation activity and stability.

Owner:PETROCHINA CO LTD

Alkyne-rich C4 fraction selective hydrogenation method

PendingCN114315498AHigh selectivityImprove hydrogenation activityHydrocarbon by hydrogenationHydrocarbon purification/separationAlkadieneButene

The invention relates to an alkyne-rich C4 fraction selective hydrogenation method, which comprises the following steps: by taking alkyne-rich C4 fraction after butadiene extraction as a raw material, under the action of a catalyst, carrying out selective hydrogenation on alkyne and alkadiene to obtain butene by adopting an adiabatic fixed bed reactor, and under the adopted process operation conditions, the molar ratio of hydrogen at the inlet of the reactor to the sum of the content of total alkyne and alkadiene is 1.5-2.5; the reaction inlet temperature is 30-80 DEG C, the reaction pressure is 1.0-3.0 MPa, and the liquid volume space velocity is 10-25 h <-1 >. The catalyst at least contains four components of Pd, Bi, Ni and Cu, and Ni, Cu and a small amount of Pd are loaded by adopting a microemulsion method and are distributed in macropores of the carrier. Bi and most Pd are loaded by adopting a traditional solution impregnation method and are distributed in small holes of the carrier. By adopting the method disclosed by the invention, the C4 fraction rich in alkyne after butadiene extraction can be effectively utilized, the resource waste is reduced, and meanwhile, the hydrogenation method disclosed by the invention has the characteristics of high anti-coking performance and good operation stability.

Owner:PETROCHINA CO LTD

Pre-hydrotreatment method of reforming feedstocks

ActiveCN102268285BReduce energy consumptionEasy to operateMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentCatalytic reformingAlkaline earth metal

The invention provides a pre-hydrotreatment method of reforming feedstocks. The pre-hydrotreatment process undergoes in the conditions that: the reaction inlet is at a temperature of 200-320DEG C, the operation pressure is over 2.4MPa, the volume space velocity of fresh raw oil is 4-12h<-1>, and the volume ratio of hydrogen to oil is 50-300; the hydrotreatment catalyst employed takes silicon-containing alumina as the carrier, cobalt and molybdenum as the active constituents, boron and alkali metal and / or alkaline earth metal as the auxiliary agents, and the precursor of the silicon-containing alumina carrier is amorphous silica-alumina containing pseudo-boehmite, which is obtained by preparation of an amorphous silica-alumina slurry and a pseudo-boehmite slurry first, followed by mixing and ageing of the two slurries, and the post-treatments of filtering, washing and drying. The method of the invention can be used to treat catalytic reforming feedstocks of high sulfur and nitrogen content as well as high olefin content in a low pressure condition, and can provide qualified feedstocks with sulfur and nitrogen content both less than 0.5 microgram / gram for catalytic reforming units.

Owner:PETROCHINA CO LTD

A kind of pre-hydrogenation treatment method of C4 alkylation raw material

ActiveCN108865243BHigh selectivitySuitable for acidityHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystAlkylation unit

The invention relates to a method for pre-hydrogenation of carbon tetraalkylation raw materials, which adopts a palladium-molybdenum series catalyst and a fixed-bed reactor. The hydrogenation process conditions are: reaction temperature is 30-75°C, and reaction pressure is 1-3MPa. , liquid airspeed is 2~10h ‑1 , the molar ratio of hydrogen to butadiene is 1 to 10; the palladium-molybdenum catalyst used is prepared with a nickel-containing alumina carrier with a specific crystal form, which can make the catalyst have suitable acidity and high active metal utilization rate, and can Significantly improve the butadiene hydrogenation activity and selectivity of the catalyst. By adopting the hydrogenation treatment method of the present invention, the carbon tetraalkylation raw material pretreatment device can effectively remove the impurity butadiene at a relatively high feed space velocity and with basically no loss of monoolefins in the hydrogenation product. , which has a very obvious and good effect on improving the environmental and economic benefits of subsequent alkylation units.

Owner:PETROCHINA CO LTD

A kind of selective hydrogenation method

ActiveCN108865242BImprove hydrogenation performanceImprove stabilityHeterogenous catalyst chemical elementsRefining by selective hydrogenationPtru catalystHydrogenation reaction

The invention provides a selective hydrogenation method, which adopts a fixed-bed reactor. The reactor is equipped with a Pd-Ag series hydrogenation catalyst. The cracked gasoline and hydrogen are mixed and preheated before entering the reactor. The hydrogenation process conditions are: reaction Temperature 30~120℃, reaction pressure 2~6MPa, space speed 0.5~4h ‑1 , the volume ratio of hydrogen to oil is 100~600:1; part of the hydrogenation product is used as an internal cycle of the first-stage hydrogenation reaction, and the other part is sent to the second-stage hydrogenation reactor for hydrogenation and refining. The catalyst prepared by using the nickel-containing alumina carrier with a specific crystal form prepared by the present invention can greatly improve the dispersion and utilization rate of active metals. At the same time, the addition of selected co-active components has a synergistic effect and improves the performance of the catalyst. Hydrogenation performance and selectivity.

Owner:PETROCHINA CO LTD

A method for selective hydrogenation of carbon eight fractions of pyrolysis gasoline

ActiveCN108865241BImprove hydrogenation performanceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationPtru catalystFixed bed

The invention provides a method for removing phenylacetylene by selective hydrogenation using the C8 fraction of cracked gasoline as raw material. The C8 fraction is preheated and then enters a fixed bed hydrogenation reactor. A lower feeding mode is adopted. The reactor is loaded with There is a catalyst, and the hydrogenation process conditions are: inlet temperature 10~70℃, space velocity 0.1~6.0h ‑1 , the pressure ranges from 0.1 to 2.0MPa, and the volume ratio of hydrogen to fresh oil is 1 to 100:1; the hydrogenated product is used as the raw material for extracting styrene. The Pd-Mo catalyst prepared by using the nickel-containing alumina carrier with a specific crystal form prepared by the present invention can greatly improve the dispersion and utilization rate of active metals. At the same time, the addition of selected active components has a synergistic effect. Improve the hydrogenation activity and selectivity of the catalyst.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com